InfraTec GmbH Infrarotsensorik und Messtechnik

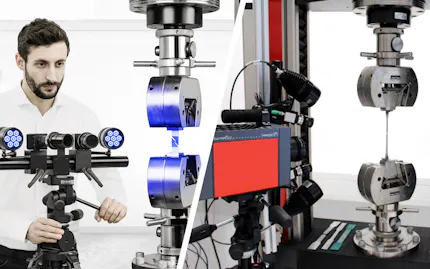

Founded in 1991, the Dresden-based company InfraTec that ever since has been managed by its owners, offers a wide range of high-quality, innovative products and services in the field of infrared technology. About 240 staff members are facing the market’s demands as a challenge that they meet with detailed expertise, daily commitment and a high degree of quality awareness. A best possible consultation, an exemplary service and tailored product design, all by in-house development and production capacities, are used in order to fulfil the customer’s demands at the highest possible level. Therewith, InfraTec contributes considerably to the sustained success of its customers.

About InfraTec GmbH Infrarotsensorik und Messtechnik

Certificate ISO 9001:2015

The high product quality of all InfraTec products is based on both a sound and permanent development process as well as on an optimised production. The focus of all processes concentrates on the satisfaction of our customers. A process definition is made by ISO 9001, the certified quality management system.

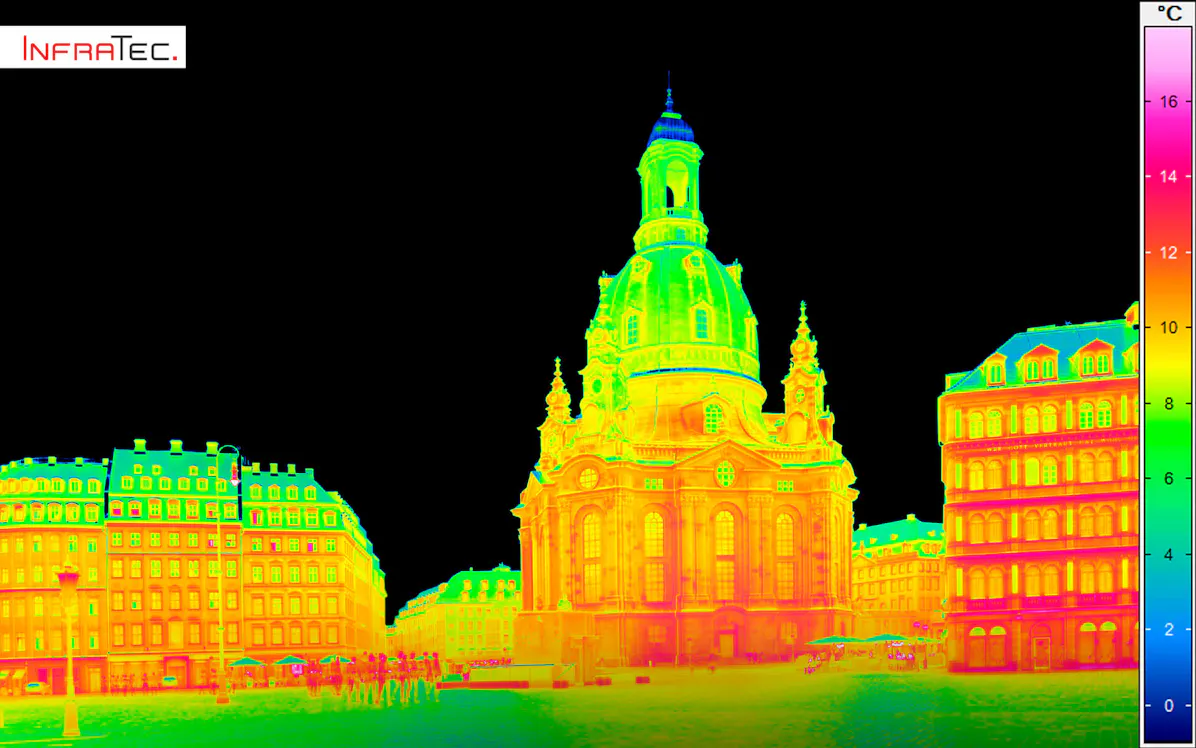

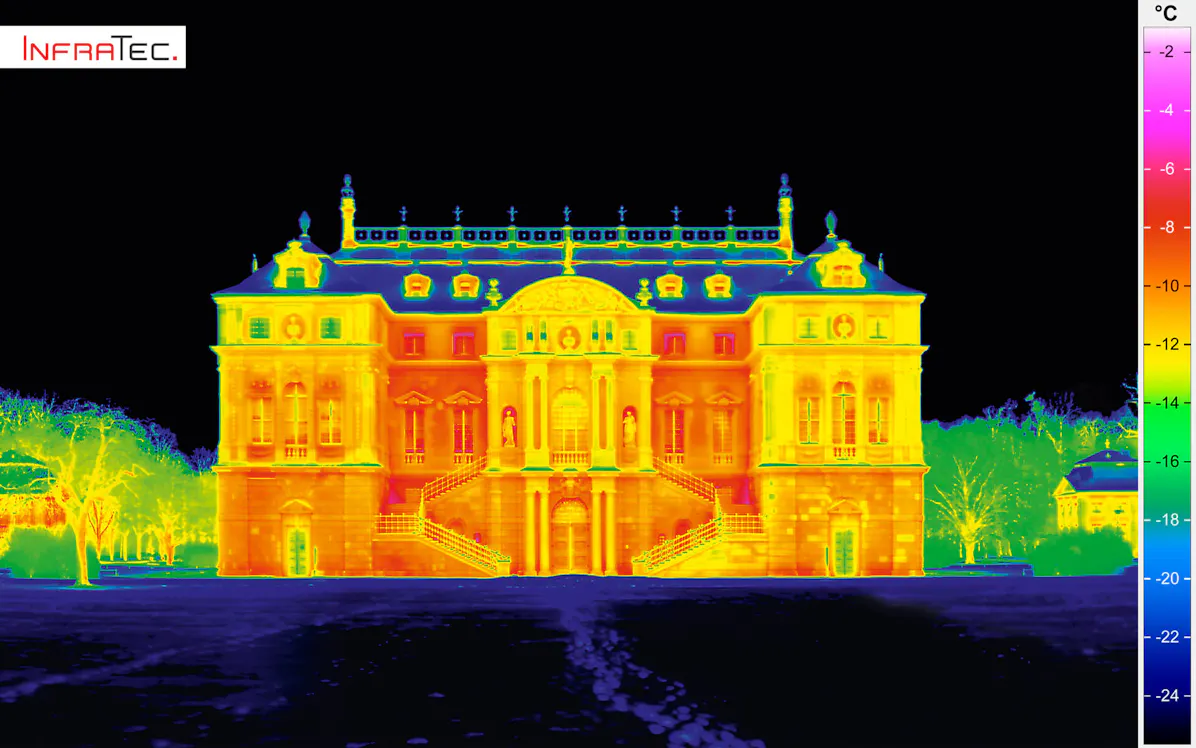

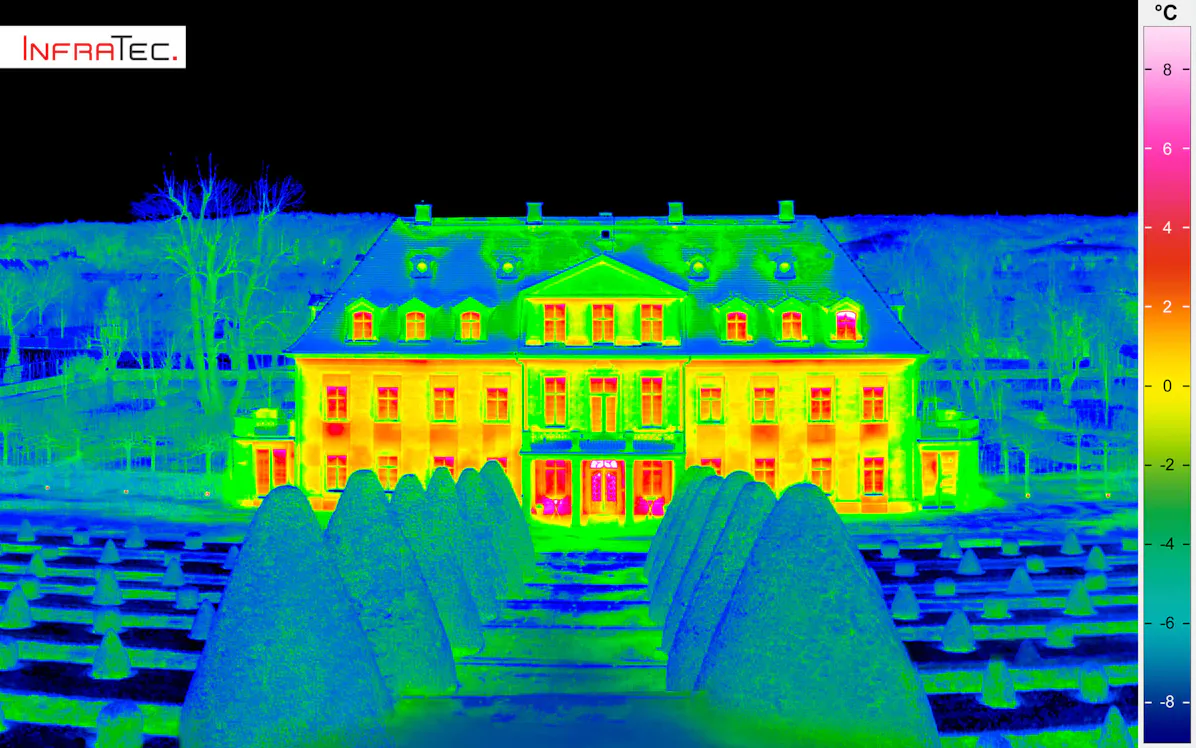

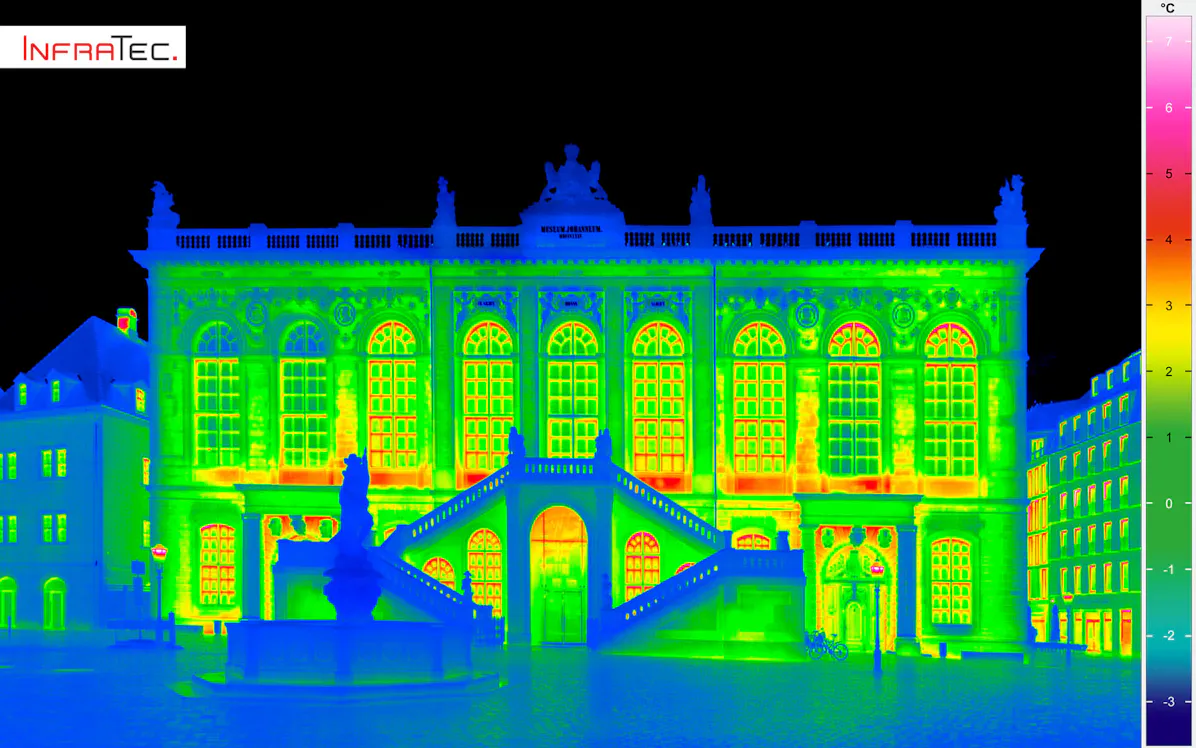

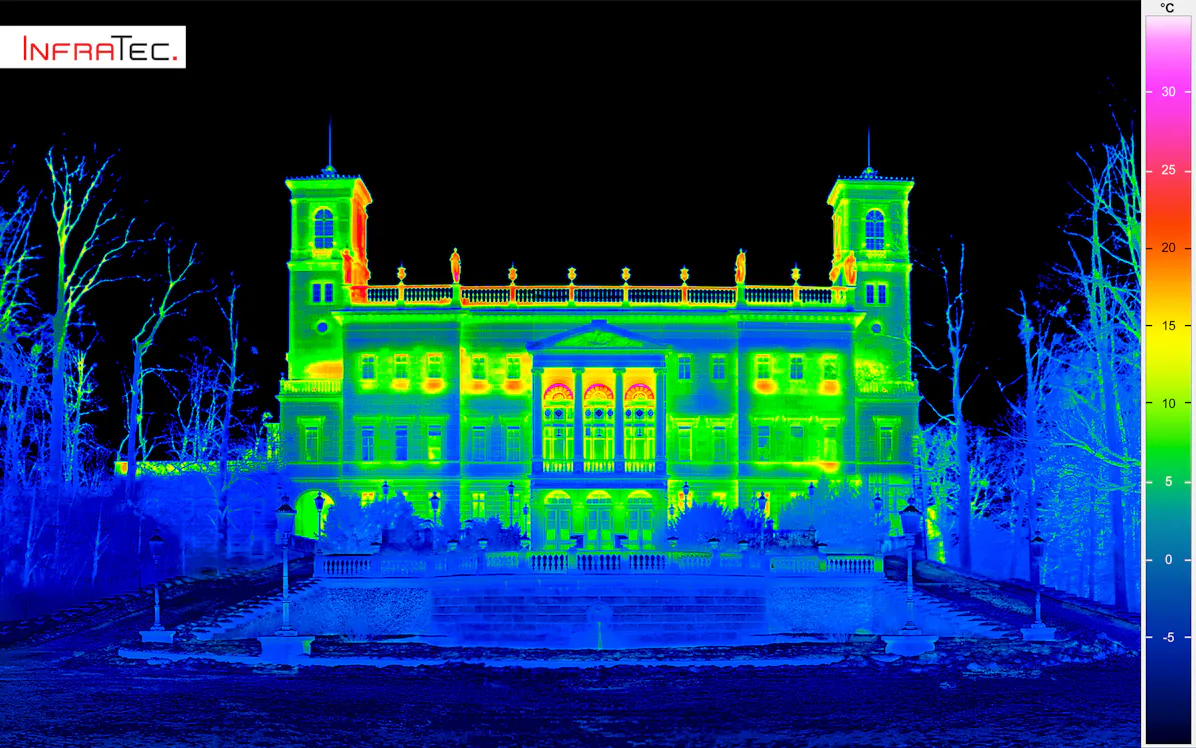

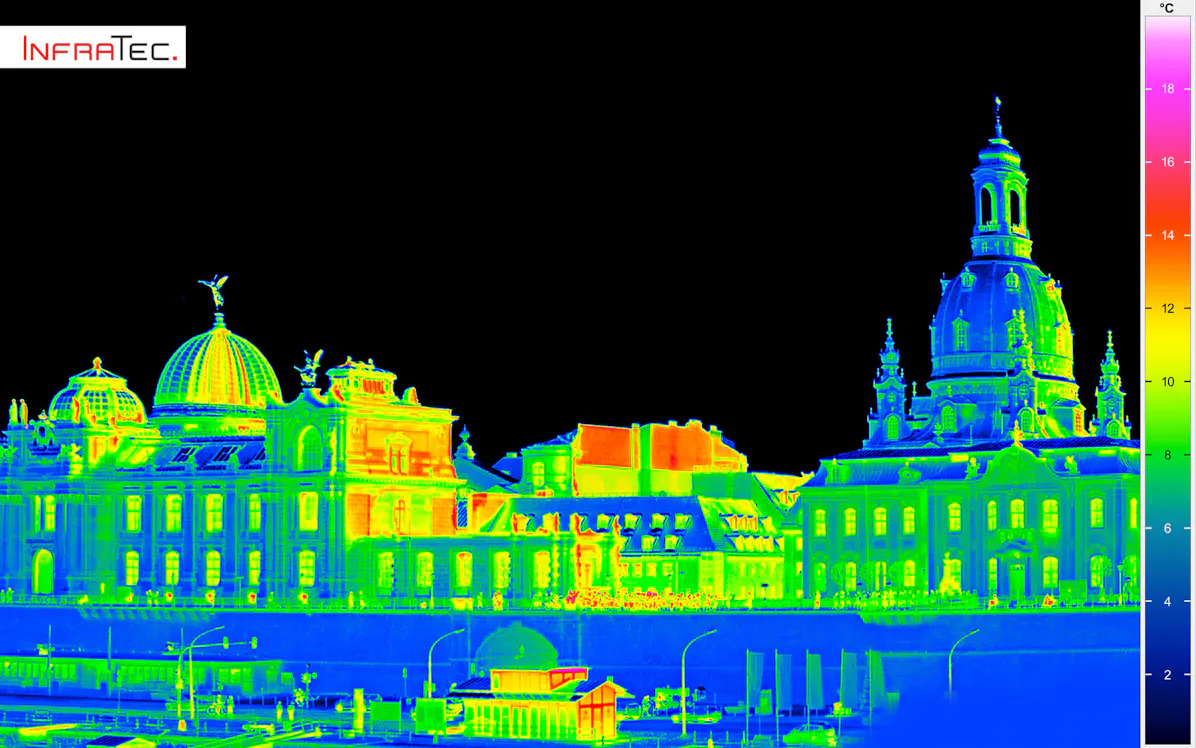

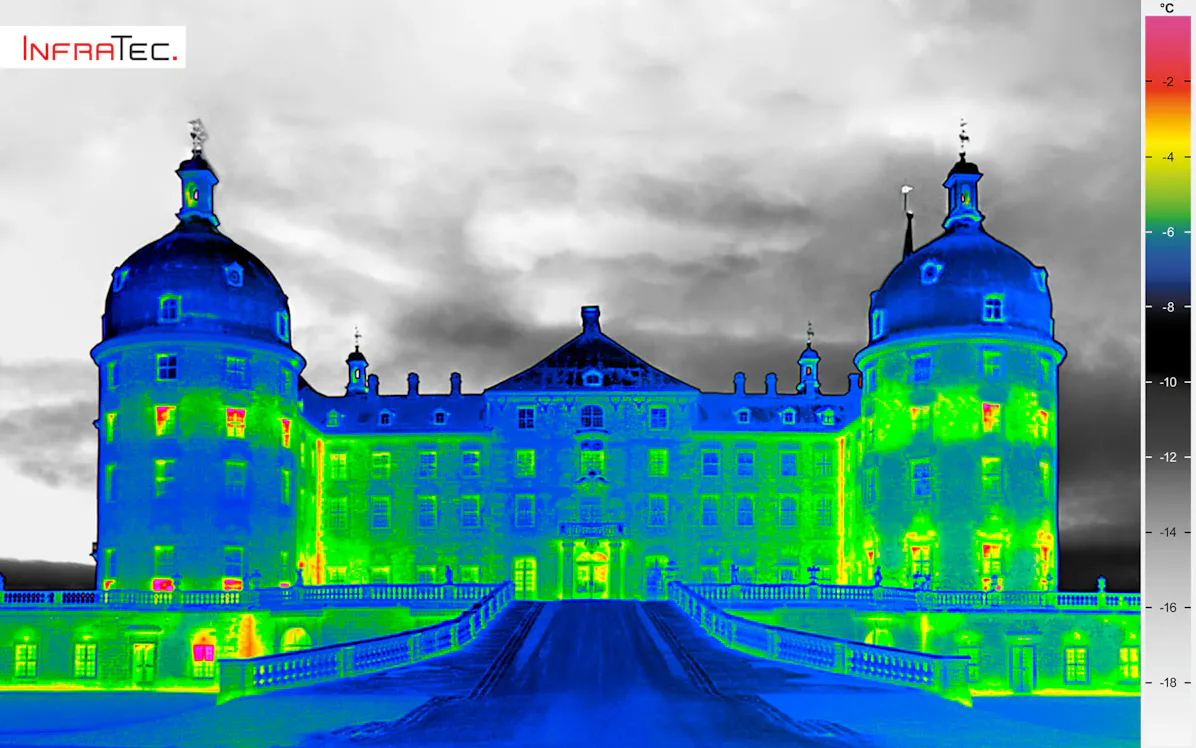

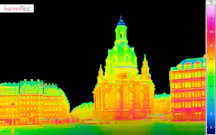

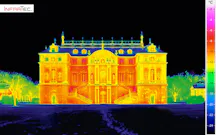

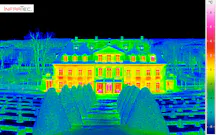

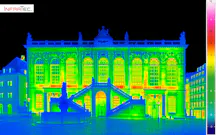

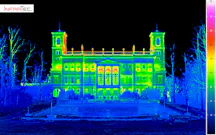

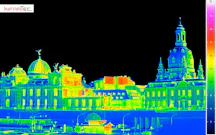

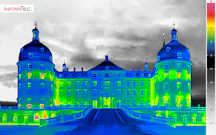

Dresden and its Surroundings in Infrared Light

InfraTec Image Brochure

As Europe’s leading specialist for infrared sensors and infrared measurement technology, we develop, manufacture and distribute sensor components and camera systems in business divisions of the same name.