Topics of the Current Issue

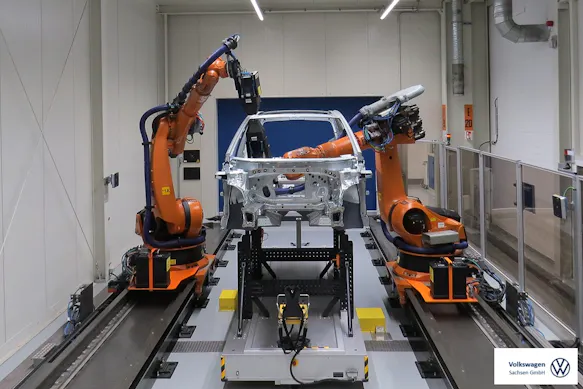

For 35 years, InfraTec has been synonymous with precise infrared thermography. The latest edition of our newsletter provides a brief review of our company history and introduces our new LWIR camera for highly dynamic processes. It also offers insights into automated quality assurance, flexible OEM solutions, and proven applications in industry and research. You can also find out how thermography, AI, and innovative system solutions create measurable benefits.

35 Years of InfraTec: From Engineering Consultancy to Global Company

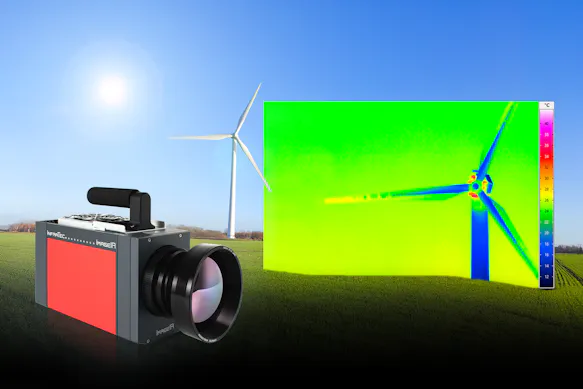

Precision Meets Perfection: Innovative Functions of the ImageIR® Series

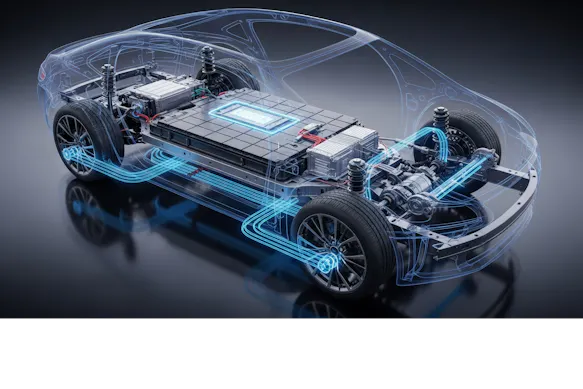

InfraTec OEM Cameras: Thermography-based Solutions for Industrial Applications

Research and Development: Thermography Forms the Basis for Reliable Forecasts

Knowledge: Request the Lock-in Thermography White Paper Today

We hope you enjoy reading our Infrared Reflexions and that we can continue to inspire your enthusiasm for the world of thermography.