![Online Event - Thermography and Digital Image Correlation Online Event - Thermography and Digital Image Correlation]() 2023-07-27Online Event: Thermography and Digital Image CorrelationA winning team in the materials and components testing fieldRead onDownload ZIP-File (1492 kB)

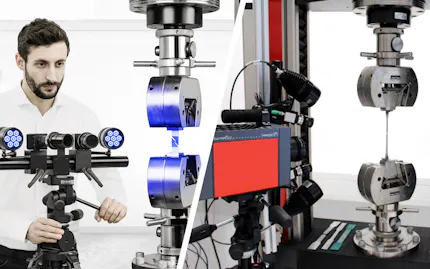

2023-07-27Online Event: Thermography and Digital Image CorrelationA winning team in the materials and components testing fieldRead onDownload ZIP-File (1492 kB)In the field of materials testing, numerous methods have been established including infrared thermography. Often, it is the combination of different methods that enables the desired results for component characterisation. For example, you can analyse displacements and mechanical deformations of material samples and components parallel with its thermal reaction.

![InfraTec Webinar: High-Resolution Aerial Thermography InfraTec Webinar: High-Resolution Aerial Thermography]() 2023-07-05Online Event: High-Resolution Aerial Thermography (September 2023)The Infrared Eye in the Sky – Aerial Thermography with InfraTecRead onDownload ZIP-File (1827 kB)

2023-07-05Online Event: High-Resolution Aerial Thermography (September 2023)The Infrared Eye in the Sky – Aerial Thermography with InfraTecRead onDownload ZIP-File (1827 kB)In the upcoming free of charge InfraTec online event you learn more about the benefits, types and challenges of aerial thermography and get more information on applications for thermography in airborne remote sensing.

![Thermography Compact – Enter the World of Infrared Technology Thermography Compact – Enter the World of Infrared Technology]() 2023-07-04Thermography Compact – Enter the World of Infrared Technology (August 2023)Experience thermography – technical lectures and demonstrations plus professional exchanges.Read onDownload ZIP-File (1827 kB)

2023-07-04Thermography Compact – Enter the World of Infrared Technology (August 2023)Experience thermography – technical lectures and demonstrations plus professional exchanges.Read onDownload ZIP-File (1827 kB)On 30 August 2023,, interested parties and thermographers from science and industry will have the opportunity to learn more about the possibilities of thermography in the demanding field of research and development.

![InfraTec press release online event flow analysis InfraTec press release online event flow analysis]() 2023-05-03Online Event: Flow Analysis Using Thermal ImagingDetermine flow properties with infrared camerasRead onDownload ZIP-File (1539 kB)

2023-05-03Online Event: Flow Analysis Using Thermal ImagingDetermine flow properties with infrared camerasRead onDownload ZIP-File (1539 kB)Thermography enables the analysis of flows by visualising characteristically thermal signatures, which are caused by different heat transfer coefficients. Thus, even the smallest flow-induced temperature gradients can be detected without influencing the flow behaviour.

![Final event of "BeING Inside" project week Final event of "BeING Inside" project week]() 2023-04-12Thermal Imaging Projects Inspire Engineers of the FutureIn the context of the "BeING Inside" project week, pupils and students realised a company projectRead onDownload ZIP-File (15716 kB)

2023-04-12Thermal Imaging Projects Inspire Engineers of the FutureIn the context of the "BeING Inside" project week, pupils and students realised a company projectRead onDownload ZIP-File (15716 kB)Since 2017, the Technical University of Dresden has organised the "BeING Inside" practical project week for A-level pupils and students in semesters 1 to 5 with an enthusiasm for engineering. This year, InfraTec supported the event as a cooperation partner, during which an industrial project was simulated under close-to-reality conditions.