Inspection of District Heating Pipelines Using Thermography

District heating is generally regarded as an extremely efficient and environmentally friendly form of energy supply. Based on industrial waste heat or renewable energy sources, it offers the possibility of heating water and thus supplying private, commercial and industrial customers. Netze Duisburg GmbH is doing to control the city's entire district heating network supported by InfraTec infrared cameras.

Several Hundred Kilometres of Pipelines in Focus

Peter Becker, working at the district heating service department at Netze Duisburg GmbH, is one of the experts in handling these cameras. He and his team use InfraTec thermography systems to regularly inspect the district heating network for possible leaks and check the sleeves of plastic-coated pipes for perfect thermal insulation. "The network covers almost 465 kilometres," says Becker. "So we have to monitor several kilometres for water leakage."

InfraTec Solution

Netze Duisburg GmbH

www.netze-duisburg.de

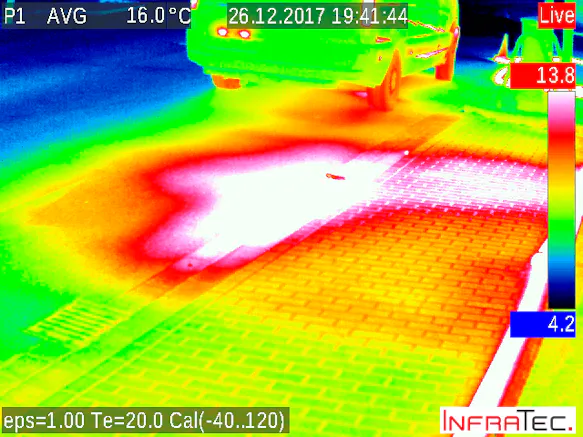

Infrared camera

VarioCAM® HDx research

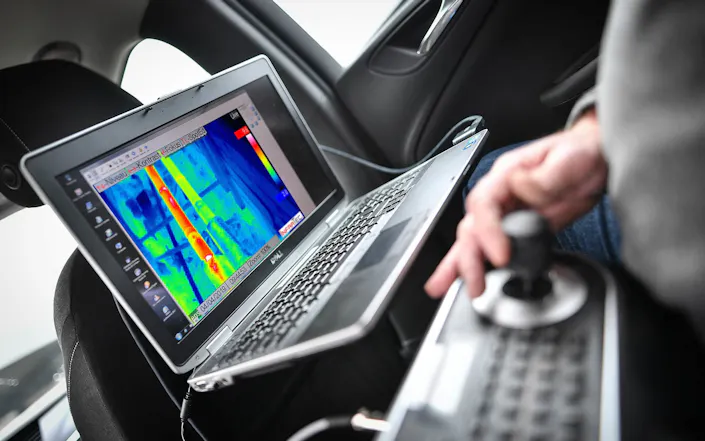

Not a job to be accomplished on foot. Therefore, an infrared camera of the VarioCAM® HDx research 600 series is mounted on the roof rack of a car with a pan/tilt head. Its robust light metal housing, combined with the LEMO® plug connections that maintain the degree of protection, ensures that the system is not affected by any weather conditions. The custom-built design includes a cable entry into the vehicle interior. Here, Peter Becker and his colleagues can monitor and evaluate the recordings live on the monitor of their notebooks. „Wherever a leak has formed, even small temperature differences can be clearly seen on the road surface. In this way, we can inspect a large area of the district heating network within a short period of time," explains Peter Becker. The consumer will not notice any of this. The monitoring is basically carried out during regular network operation and proves to be extremely accurate.

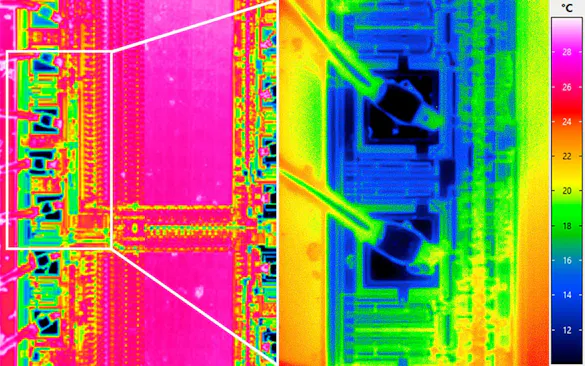

Thermal images can be viewed and evaluated live while driving, for example to inspect joints. The excellent technical characteristics of this thermographic camera enable reliable leakage location instantly even if leaks are only distinguished from the environment by small temperature gradients. The road to success: Its high-quality microbolometer detector in the format (640 × 480) IR pixels and the capability to detect smallest thermal differences up to 30 mK.

Thermography Enabling Fast Maintenance

Once a leak has been identified, Peter Becker notifies his colleagues responsible and repairs may commence. Efficiency and promptness are therefore the decisive advantages he sees in the use of infrared cameras for his work. This is complemented by a high degree of flexibility. Finally, if desired, the camera can also be removed from the pan/tilt head and simply used as a hand-held device. The 5.6 inch extremely large and very bright colour TFT display allows the immediate evaluation of recordings, even if the camera is not live connected to a computer. This considerably expands the range of applications for the thermography system. Within the Netze Duisburg GmbH, this technology is an extremely effective element of leak detection, which complements other leak detection methods such as monitoring of synthetic jacket pipe systems based on moisture indicators and pressure tests in network areas.

About 70,000 households and companies of the Ruhr metropolis are supplied via the predominantly buried district heating network. These are about 35% of the almost 500,000 inhabitants of the city. The high-pressure supply lines of the network, in which water as a heat transfer medium at temperatures of up to 125 degrees Celsius reaches the consumers, are very well insulated. Thus, only 5 degrees of cooling can be seen as a loss on the way. District heating of Duisburg not only heats residential and commercial premises, but also generates hot water via a domestic water heater.