Waste Bunker Fire Detection System – WASTE-SCAN

Thermographic Fire Detection and Prevention in Waste Bunkers

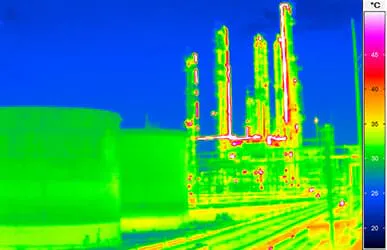

Monitoring of waste bunkers in waste-to-energy plants, warehouses and open areas for early fire detection

Timely detection identification and localization of critical temperature conditions

Contactless, high-resolution temperature measurement at great distances for the required early fire detection in waste bunkers

Automatic early detection of bunker fires

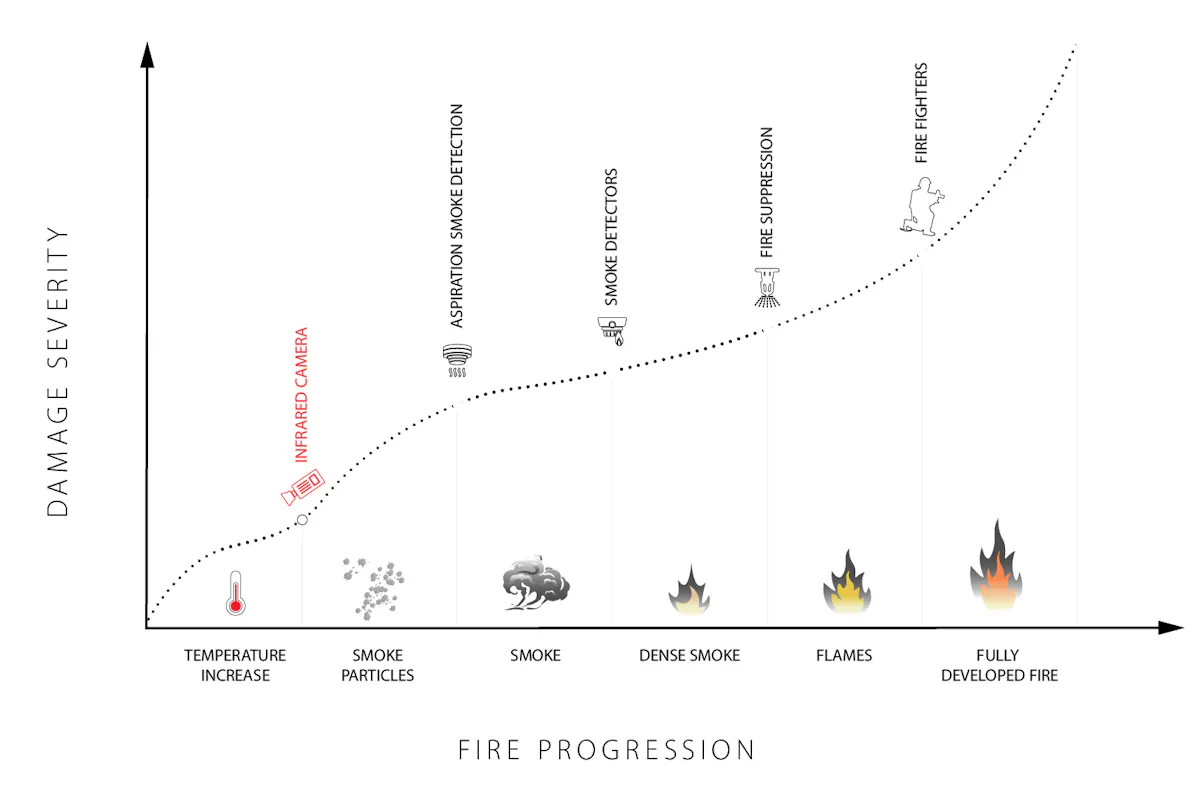

Early Fire Detection Systems

WASTE-SCAN Supports Fire Detection and Protection in Waste Bunkers

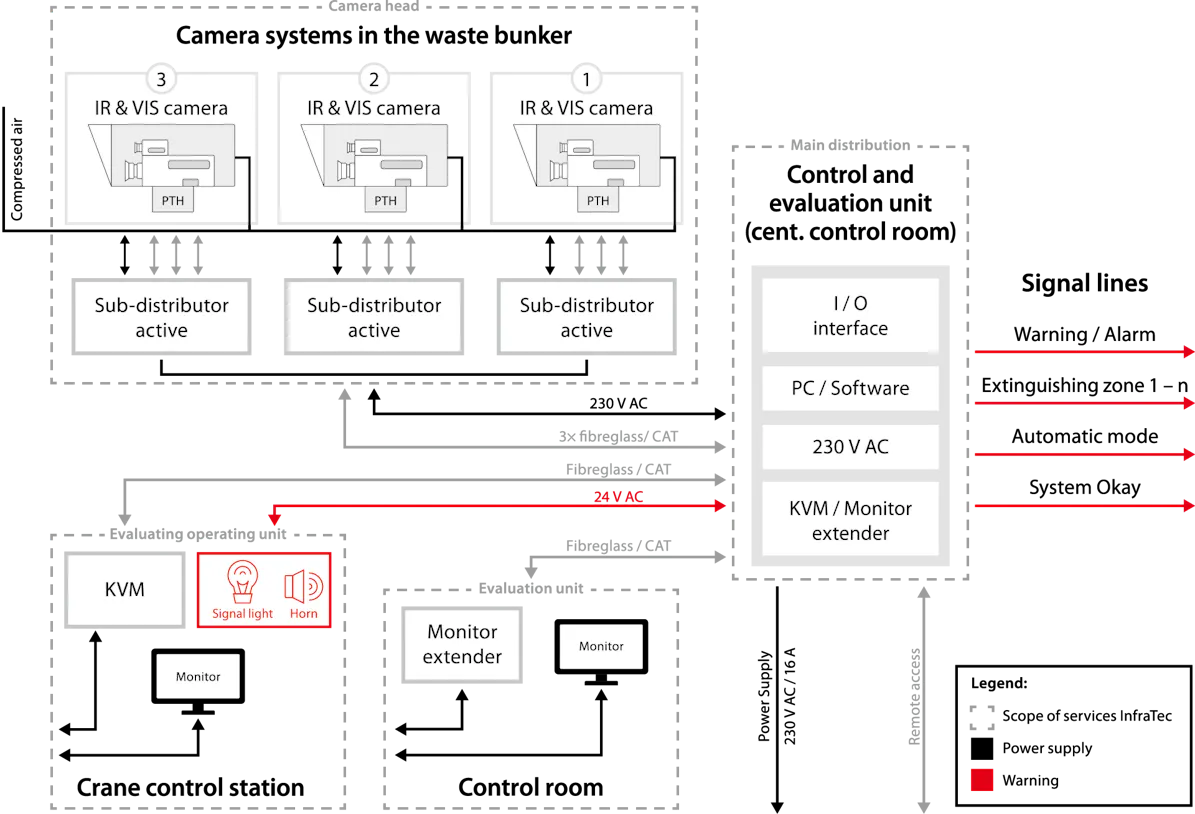

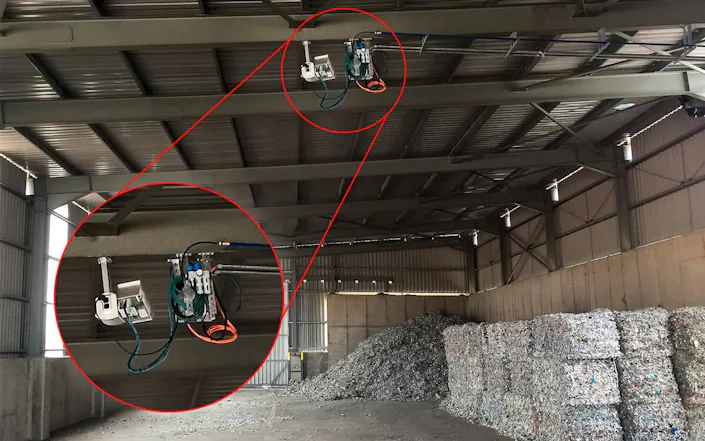

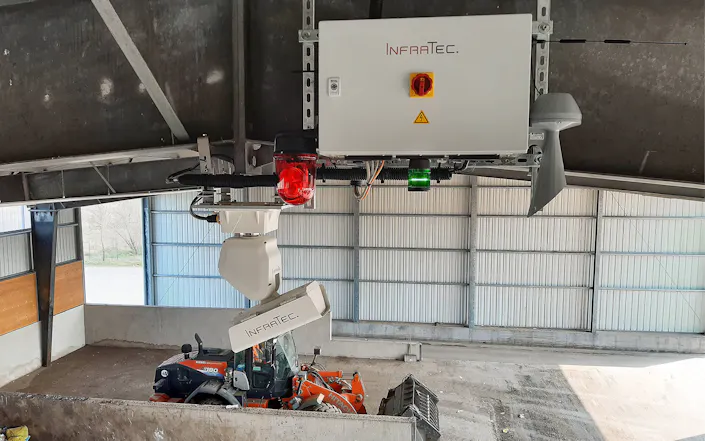

Waste incineration plants are subject to fire safety regulations since it can cause danger to environment and its local residents. Thus, InfraTec offers its thermographic solution WASTE-SCAN in particular with regard to the 17th German federal immission protection ordinance for early fire detection and fire fighting. It is a consistent further development of the early fire detection system FIRE-SCAN for the special needs in the waste and power industry on the operation of waste bunkers. The application of WASTE-SCAN reduces the danger of fire in waste bunkers and, therefore, the escape of toxic gases. A fully remote-controlled solution from the bunker control room or the crane cockpit enables a flexible work for plant operators. When necessary, they are additionally supported by a visual camera for a better orientation. Critical temperature areas can be displayed directly in the visual image. The infrared camera itself is enclosed in a robust housing with a blow-off system for the camera lens and, therefore, can also operate under adverse ambient conditions.

Complete Storage Space Monitoring

Works even with one single thermographic camera by application of pan-tilt head

Automated scanning of several inspection sections

Maximum cycle time two minutes

Sector position accuracy < 0.2°

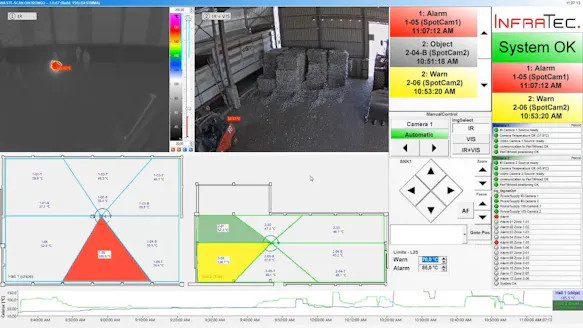

Switch to manual control for observing suspect spots and evacuating critical objects

Pilot control of extinguishing zones according to a pre-defined zone table

Support of multiple recipes (day and night time operation)

Detect automatically sources of interference

High-resolution Thermographic Camera

Quality made in Germany

Uncooled FPA-Microbolometer detectors of various formats

High geometrical resolution and thermal sensitivity

High-contrast, low-noise thermal image

Localisation of hot spots even under dusty or smoky conditions

Spectral range (7.5 … 14) μm; frame rate 50 / 60 Hz

Real-time data acquisition (Gigabit Ethernet)

Internal automatic calibration

Rugged housing for industrial applications IP65 (stainless steel*)

Extremely high level of system availability

Additional digital colour video CCD camera*

Product Flyer

Get all the information you need at a glance in our product flyers

Would You Like to Know More?

It is not unusual for tasks to be associated with special requirements. Discuss your specific application needs with our specialists, receive further technical information or learn more about our additional services.

Powerful WASTE-SCAN-Software

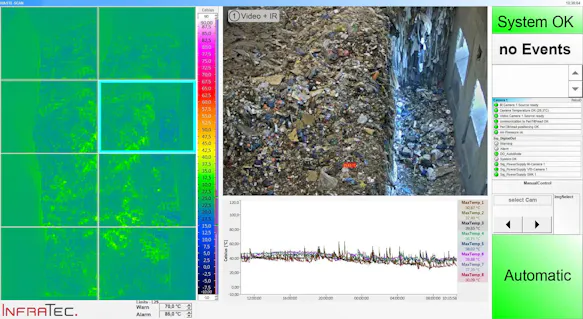

Continious display of current thermal images of all sections (mosaic-overview)

Simultaneous display of live image (thermal image and colour video)

Camera and system status indication

Merging of live images of thermographic and video camera

Recording of maximum, minimum and average temperature of each section

Single or multiple-camera system available

Graphics of temperature-time profile of all sections

Logging of operations

Filing of image data

Detecting and marking of sources of interference, e.g. wheel loaders

Alarm Release

Automatic alarm release when temperature values exceed critical thresholds

Multi-level alarm functions with adjustable warning and alarm threshold values

Analysis of long-term temperature trend with adjustable time basis

Documentation of alarm situations for analysing fire formation

Wide range of system versions due to modular design concept

Customised System Design

Suited for sustained continious operation 24 hours / day

Transfer of thermal images from the camera to a central control room

Flexible wiring technology (copper or fibre optics)

Versatile solution for display and operation in the crane control station, the control room and / or the gate

Uninterruptable power supply*

System maintenance at PC in control cabinet (via remote control*)

Large surface black body reference for atmosphere transmission compensation*