Power Electronics – Efficient Control of the Futures Energy

The energy efficiency of electronic components is becoming increasingly important in numerous fields of application. And that is not all: in our electronic and high-tech age, the demand is for even faster active components, higher power densities of miniaturised systems as well as absolute reliability. Along with this, there is the request for environmentally conscious resource procurement and the requirement that the increase in performance of modules should run parallel to lower energy consumption.

Silicon-based microelectronics have repeatedly reached new performance peaks in recent years. The number of transistors on a chip doubled almost every two years and so did the computing power of processors. But the limits have almost been reached, which is why the Institute of Electrical Engineering and Information Technology (ET&IT) and the Institute of Materials Science are working on new semiconductor materials. These are two of the three institutes of the Faculty of Technology at Christian-Albrechts-Universität zu Kiel (CAU Kiel). Research topics of this faculty include renewable energy, sensor technology and electromobility.

InfraTec Solution

Christian-Albrechts-Universität zu Kiel

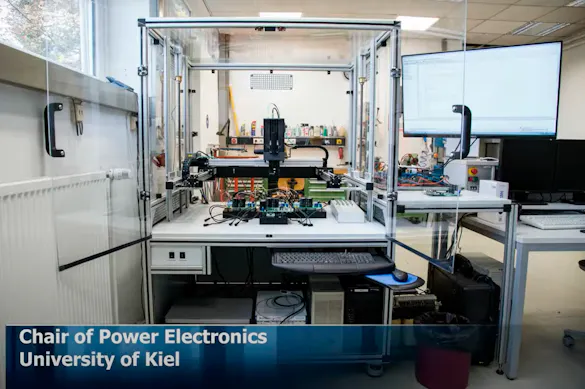

Faculty of Technology, Chair of Power Electronics

https://www.uni-kiel.de/en/

M. Sc. Johannes Kuprat

Prof. Dr.-Ing. Marco Liserre

Thermal imaging system:

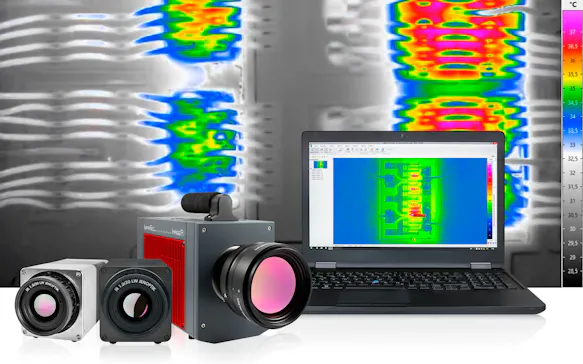

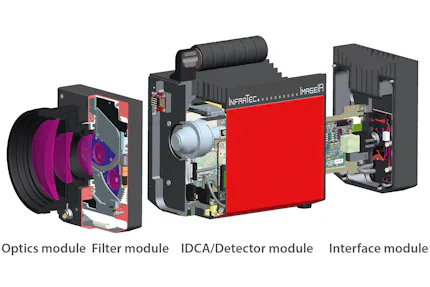

ImageIR® 8300 infrared camera

Future Semiconductor Materials – New Opportunities and Challenges

More powerful semiconductor materials are the prerequisite for the electronics market of the future in general and for power electronics in particular. Electronic systems should perform better and at the same time require less energy. This is a goal that manufacturers of electric cars, for example, have defined for themselves. The procurement of the resources used should be as environmentally friendly as possible and their use as efficient as possible.

What is required now are more powerful semiconductor materials for significantly smaller components. For this reason, power semiconductors such as gallium nitride (GaN) and silicon carbide (SiC) are overtaking silicon (Si), which has been used up to now. GaN transistors in particular enable a smaller size and potentially generate lower costs. They have a significantly lower conductive resistance for the same size of electronic components and achieve faster commutations, which in turn results in lower switching losses. The lack of reverse recovery charging also allows for higher frequency and power density. All of the above factors offer significantly higher energy efficiency than silicon-based technologies.

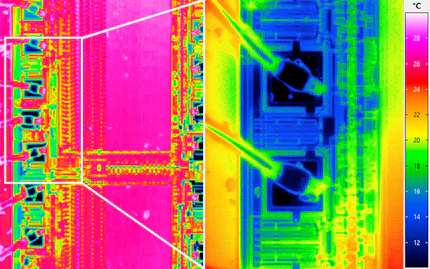

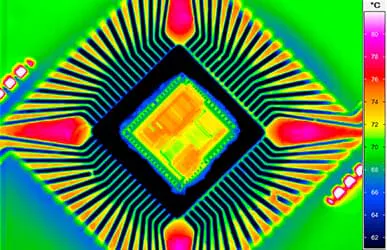

However, with this increase in performance and parallel to advancing miniaturisation, the requirements in the field of research and development of power electronics are changing. Above all, temperature is becoming an even more critical parameter for all power systems. GaN-based power modules, for example, operate at temperatures of up to 600 °C - higher than other silicon-based electronics. To ensure that the individual elements withstand the high thermal stress and do not fail prematurely, thermal management is extremely important. The GaN transistors operate with very high switching frequencies, resulting in equally rapidly cycling temperatures. This places high demands on the technology used for monitoring and/or process optimisation.

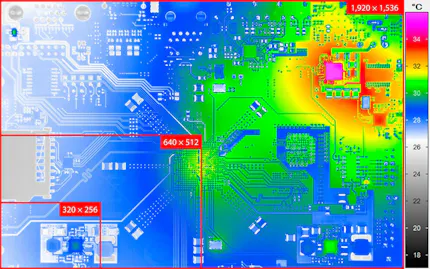

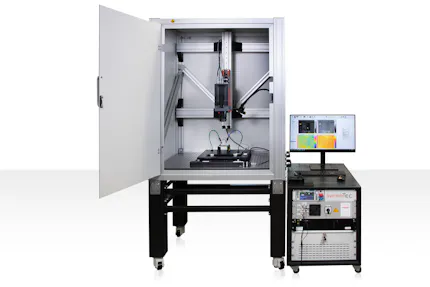

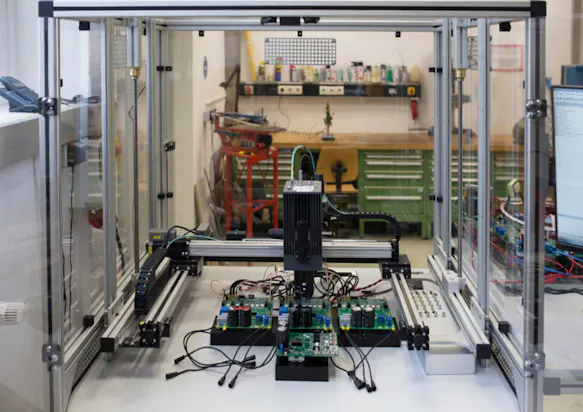

Thermography in Use for Power Electronics

Since both, the electronic components and the transistors, are very small, the infrared camera to be used must meet certain requirements. For this reason, a measurement set-up suitable for this purpose was designed for the CAU, in which a cooled thermography system of the ImageIR® infrared camera series from InfraTec is used. With its high thermal resolution, it detects even the smallest temperature changes and, due to its excellent geometric resolution, resolves structures of less than 50 µm in size in this application even with standard lenses. The ImageIR® infrared camera used has a cooled photon detector enabling the imaging of particularly fast processes. Switching peaks can thus be analysed without any problems. The non-contact measurement is non-destructive and enables the detection of several critical points, as the complete object is imaged. A further advantage is the non-complicated MATLAB interface via the IRBIS® Software Development Kit (SDK) from InfraTec.

Scientists at the Faculty of Technology at Christian Albrechts University (CAU) in Kiel are making use of these advantages. The changes and developments of temperatures and their distribution in various semiconductor materials in the field of power electronics are being researched here in order to optimise processes and techniques. In particular, it is about U-Heart: a new concept of isolated DC-DC converters with multiple connections, which were developed to achieve the highest reliability together with high energy efficiency with minimal redundancy. It is equipped with a fault detection circuit that excludes a detected faulty cell from power transmission. "Self-healing" approaches are actually under development to maintain the operation of all cells and to continue operating at full power. Thus, U-Heart is a ERC grant for a proof of concept for a maintenance-friendly power converter and can be used as a multi-port converter connecting multiple voltage grids, e.g. energy storage systems (batteries, supercapacitors), renewable energy sources (solar PV modules, fuel cells, etc.) and DC loads. The development of this energy superstar also benefited from insights gained through thermography from the predecessor project Heart (ERC grant).

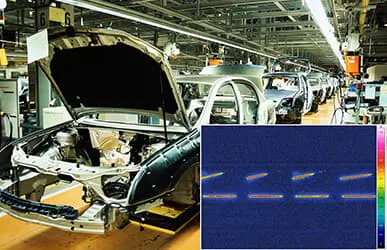

In general, it is reasonable to use thermographic cameras already in the development and creation process of new electronic components. Valid and meaningful data about the heat development in the components is obtained. This again allows, among other things, conclusions to be drawn about the performance and energy efficiency of a module, and faults are reliably detected at an early stage and can be rectified.

Thermography Solutions for Power Electronics – Precise, Non-contact and High-speed

Challenges of electronics testing

Improvement of electronics design and thermal management by understanding heat

Thermography in the various phases of electronics development and production

Important and relevant selection criteria