Thermographic Warehouse Monitoring for Fire Prevention

Warehouses, waste bunkers, or areas storing lithium-ion batteries are at high fire risk. With FIRE-SCAN, InfraTec offers a fully automated thermographic solution for early fire detection – non-contact, reliable, and continuous. In our online event, you’ll learn how the system works, what challenges to expect, and how FIRE-SCAN is already in use in various industrial environments.

Current Appointments

Thermographic Warehouse Monitoring for Fire Prevention

Thermography in early fire detection: challenges, important parameters and their influence

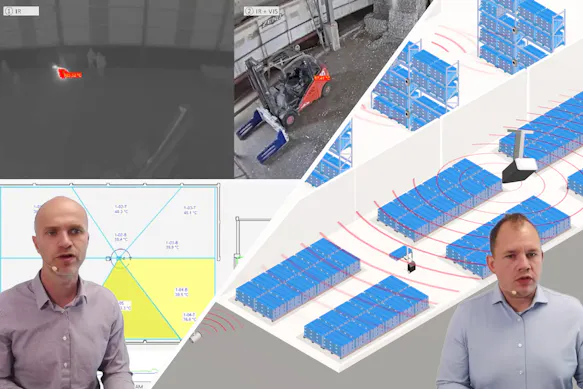

FIRE-SCAN for thermographic warehouse monitoring

FIRE-SCAN for monitoring Lithium-ion batteries

High resolution infrared cameras with pan/tilt heads

Special infrared cameras for stationary installation

Thermographic Solutions Make a Significant Contribution to Safety

Electric vehicles are conquering the world and lithium-ion batteries are finding their way into warehouses and assembly halls. However, the production, storage, recycling and transportation of energy storage systems pose risks if, for example, a fire occurs due to thermal runways. Thermography is one of the methods used to prevent such scenarios.

Learn more about the use of infrared thermography for early fire detection in storage areas and battery applications in our free online event “Thermographic Warehouse Monitoring for Fire Prevention”.

A Glance at the Event

Introduction to the physical basics of thermography

Thermography in early fire detection

Challenges, important parameters and their influence

References from practice

FIRE-SCAN for monitoring lithium-ion-batteries

Thermographic Warehouse Monitoring

At assembly stations

During battery recycling processes

Technical solutions from InfraTec

High resolution infrared cameras with pan/tilt heads

Special infrared cameras for stationary installation

Advantages and disadvantages of these solutions

Possible combinations

Question and answer session