Antarctic Building Thermography

Building thermography is a popular and established application for thermal cameras. Today the related services are frequently provided with simple “pistol” style cameras and from low-cost service providers. But when it comes to perform precision thermography you definitely need serious equipment and professional users!

The U.S. Army´s Cold Regions Research and Engineering Laboratory (CRREL) is a research facility that provides both scientific and engineering support to U.S. government organizations and its military. In addition, technical support to non-government customers is given as well. Nowadays, CRREL solves interdisciplinary problems by advancing science and engineering to complex environments, materials and processes mainly related to Earth´s cold regions. This also applies to civilian non-military applications, environmental changes and climate-change effects are an important part of the related studies as well.

InfraTec Solution

U.S. Army Corps of Engineers

Cold Regions Research & Engineering Laboratory (CRREL)

www.erdc.usace.army.mil/Locations/CRREL/

Adam LeWinter

Thermographic System

VarioCAM® HD head 800

Buildings Under Stress

The U.S. Antarctic Program is a research program that currently operates three permanent stations on the Antarctic continent:

McMurdo Station

Amundsen-Scott South Pole Station

Palmer Station

All of them are obviously subject to one of the most extreme climates on Earth: Extremely low temperatures, strong winds and heavy snowfalls continuously nag on the structures set up at those stations. Operating them needs a deep understanding of the related building engineering. Keeping the operational cost at a reasonable level is important as well. The energy-efficient design of buildings plays a major role here, which in turn can be achieved with the help of thermography.

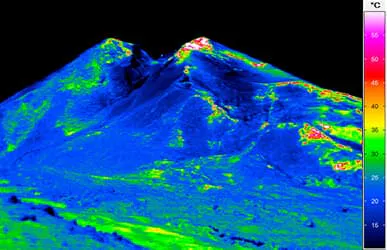

As part of a program on behalf of the National Science Foundation, the initial thermography data had been gathered at Palmer Station. The focus then was set on Amundsen-Scott South Pole Station.

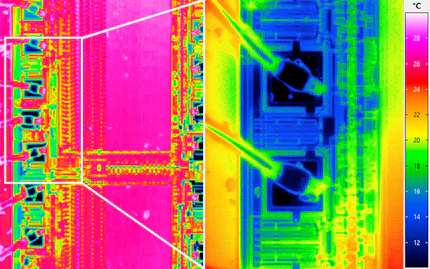

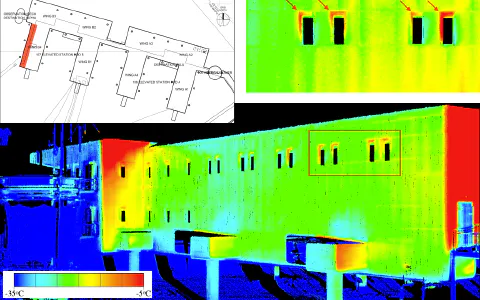

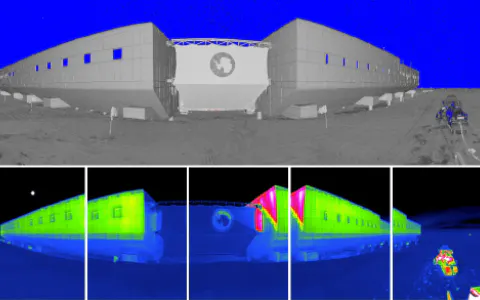

There, not only the climate is more extreme; due to the moving ice sheet underneath, the building structure is heavily stressed by this mechanical load. To establish a link between thermography data and mechanical changes CRREL combined their VarioCAM® HD head 880 with a RIEGL Laser Lidar system. The final goal of this project was the production of a thermal infrared point cloud that culminates in a full 3D model of the monitored building shell.

Amundsen-Scott´s Elevated Station is placed on supporting columns that allow individual adjustments in the order of up to 7 cm from an average level. As the station is placed on a slowly moving ice sheet it needs regular readjustments to keep its structure safe and stable. Accumulating snow amplifies this dynamic ground behaviour and the load to which the building is exposed.

Thermal Camera Meets Lidar System

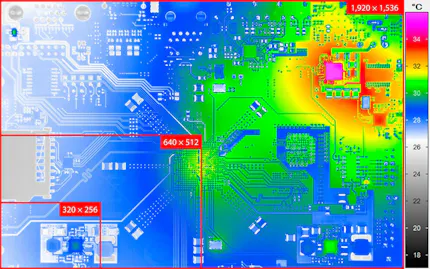

In order to combine high-resolution position data and thermographic measurements, a powerful set of instruments is required. A VarioCAM® HD 880 has been chosen because of its ruggedized design and thermographic performance. The Lidar system being used is a RIEGL VZ-1000 laser scanner. Both had been placed on a common X-Y platform. The devices can be operated down to temperatures of

-20° C, nevertheless the Amundson-Scott campaign required an additional housing since the air temperatures went down to -30 °C during the measuring period.

The actual data collection had been achieved via individual software tools: IRBIS® 3 professional with its thermography data export functionality on the camera side, RIEGL RiScan for the scanner´s part. VarioCAM® High Definition proved to be the right choice for a thermography system used in polar climates. Its all-metal IP54 housing with internal focusing and the push-pull plugs allowed seamless thermography measurements even at -30 °C, the thermal accuracy was just as good as expected, data handling via the IRBIS® software was easy to accomplish.

Overall, the elevated station’s design and construction provides a tight thermal shell with little significant heat loss observed by the LIDAR/thermography system. Adam LeWinter and his colleagues located minor SIP trim-fit issues and variations in the performance of the station’s windows and identified thermal bridging where heat was being transferred through the building’s frame. Future design and construction techniques may avoid this by ensuring there is overlapping insulation between the exterior wall and internal frame. The entrance doorways displayed little to no heat loss, validating the use of the cold store doors.

Literature and Pictures

Deeb, E.J. and A. LeWinter, 2018: Building Envelope Assessment Using Thermal Infrared and Lidar Scanning: Palmer Station, Antarctica. ERDC/CRREL TR-18-9, Hanover, NH: U.S. Army Engineer Research and Development Center.

LeWinter, A. and D.C. Finnegan, E.J. Deeb, P.J. Gadomski: Building Envelope and Infrastructure Assessment Using an Integrated Thermal Imaging and Lidar Scanning System, Amundsen-Scott South Pole Station, Antarctica. ERDC/CRREL TR-18-10, Hanover, NH: U.S. Army Engineer Research and Development Center

Technical Report (Engineer Research and Development Center (U.S.))

https://erdc-library.erdc.dren.mil/jspui/handle/11681/27385

RIEGL Laser Measurement Systems GmbH

http://www.RIEGL.com/nc/products/mobile-scanning/

Pictures: ©Cold Regions Research and Engineering Laboratory (CRREL), Adam LeWinter