FLIR – Forward Looking InfraRed

Infrared Solutions from InfraTec

The term FLIR stands for the abbreviation Forward Looking InfraRed. The abbreviation FLIR originated in the course of the further development of the infrared camera at the beginning of the 1960s. Originally a one-dimensional downward or sideways looking system on aircraft, it was then replaced by forward looking scanner cameras that no longer relied on movement of the carrier system for imaging.

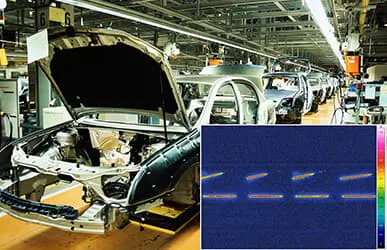

Modern FLIR are equipped with different cooled and uncooled two-dimensional imaging detector systems that reproduce thermal images in the wavelength ranges of (2 ... 14) µm. This makes FLIR ideal for people and vehicle detection in government applications, other applications include industrial and construction thermography.

FLIR Infrared Cameras for Everyday Work

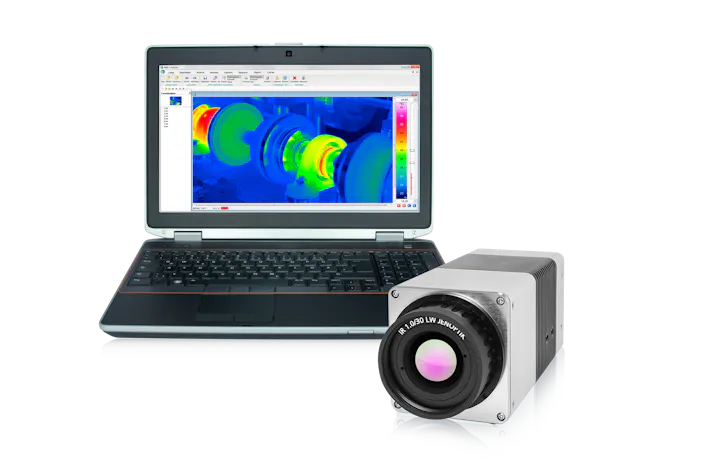

InfraTec's product range includes more than 30 thermal imaging camera models. The product range includes entry-level devices, professional and universal thermal imaging cameras, high-end solutions as well as industrial thermal imaging cameras and infrared imagers. Together we will find the right package of FLIR infrared camera, software, accessories and service for your specific application.

A Cooperation with InfraTec Offers you the Following Advantages:

Wide variety of cooled and uncooled FLIR thermal imaging cameras for stationary use

Application-specific software packages enable precise and efficient data evaluation

Turnkey thermographic automation solutions

Professional feasibility studies

Comprehensive range of services from 24-hour service hotline to extended warranties

In-house service department, e.g. for on-site support, remote maintenance and recalibration

German designed, developed and manufactured

Choose Your Infrared Camera

Choose from more than 30 infrared camera models. Our product range includes entry-level and zoom cameras as well as high-end and industrial systems.

Measuring in Different Wavelength Ranges

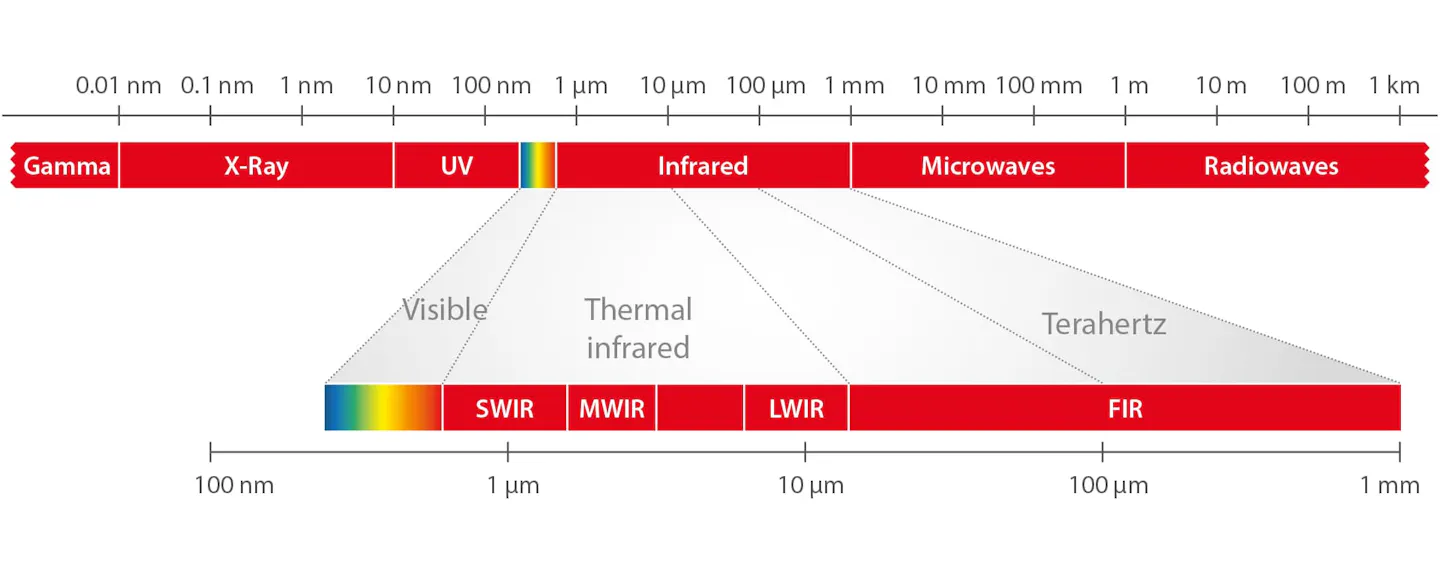

FLIR cameras are suitable for detecting infrared radiation in three main wavelength ranges: The short-wave, the mid-wave and the long-wave infrared.

InfraTec Spectral range

Short-wave Infrared (SWIR)

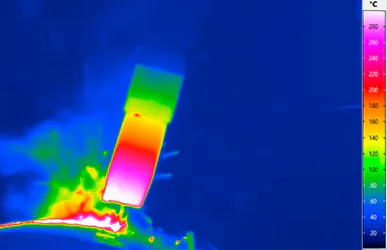

The short-wave infrared (SWIR) covers a wavelength range of (0.9 to 1.7) µm. For thermography, this range is useful for some high temperature applications. There are also SWIR ranges that allow long ranges for surveillance applications due to the low atmospheric attenuation.

Mid Infrared (MWIR)

The mid-infrared (MWIR) ranges from (1.5 to 8) μm. The spectral atmospheric absorption properties of water vapour and carbon dioxide still limit this range for outdoor applications to (2 to 5.5) µm, yet the entire MWIR range is interesting for spectral thermography of various materials. Among others, the infrared camera series ImageIR® developed by InfraTec is used for applications in this range. Models of this series have cooled focal plane array photon detectors with a native geometric resolution of up to (1,920 × 1,586) IR pixels. Solving measurement tasks over long distances is significantly more difficult in the MWIR.

Long-wave Infrared (LWIR)

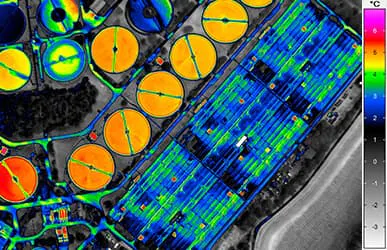

Atmospheric influences play only a minor role in the long-wave infrared (LWIR) of (7 to 14) μm. Therefore, measurement tasks can be carried out over longer distances, even outdoors. LWIR is also a very good option for monitoring solutions that require continuous outdoor use. In this wavelength range, you can choose between FLIR systems that use cooled or uncooled detectors. The latter are usually smaller, lighter and cheaper than infrared cameras with cooled detectors. In addition to the stationary camera series ImageIR®, InfraTec also offers mobile and stationary microbolometer cameras of the VarioCAM® High Definition series.

Further Information about A FLIR Camera from InfraTec

Discuss your specific application needs with our specialists, receive further technical information or learn more about our additional services.

High-end ImageIR® Cameras Series with Cooled Detectors

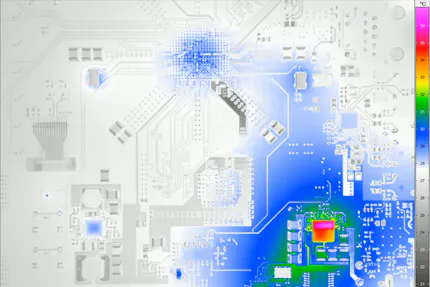

The high-end thermographic cameras of the product series ImageIR® from InfraTec meet the highest demands in research and science, for non-destructive inspection as well as for process control. The modular concept enables excellent adaption to your specific measurement and inspection tasks. Cooled photon detectors of different types (InSb, MCT), spectral sensitivity ranges and formats are used. The numerous equipment options include powerful infrared full optics, filters and rotating aperture wheels, trigger and data transfer interfaces as well as motor focus units suitable for continuous operation.

Spatial resolution with detector formats with up to (1,920 × 1,536) infrared pixels

Integrated into camera, genuine temperature measured values

Thermal resolution as low as 0.015 K

Due to Binning technology increase frame rates and thermal resolution at the same time

Analysis of high-speed dynamic temperature changes and processes

More flexibility for upgrades and changes of components

Flexible filtering by inbuilt two filter- / aperture wheels with up to 25 combinations

Precise triggering with only 10 ns jitter

Professional VarioCAM® Camera Series

More than 30 models of the VarioCAM® High Definition product series include premium infrared cameras as well as entry models to high-level thermography. The equipment versions “research” and “inspect”, which are designed for handheld operation, impress with 5.6" TFT colour displays, integrated 8 Megapixel digital cameras, high-performance uncooled microbolometer detectors and robust light-weight metal housings. The stationary “head” models allow fixed mount installation e.g. in harsh industrial environments.

High-end detectors with up to (1,024 × 768) infrared pixels

Available with unique opto-mechanical micro-scanner for up to (2,048 × 1,536) infrared pixels

Thermal resolution as low as 0.02 K

Frame rate up to 240 Hz

Handheld models utilizing a 5.6" TFT colour display with (1,280 × 800) pixels

Cameras for fixed mount use in harsh process environments as well as for computer-assisted laboratory tasks

Further Information about A FLIR Camera from InfraTec

Discuss your specific application needs with our specialists, receive further technical information or learn more about our additional services.