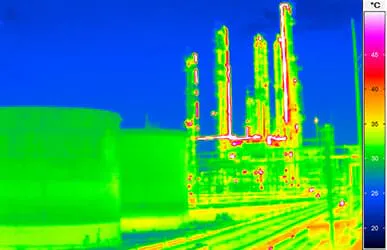

Infrared Cameras for Plant Inspection

The use of Thermal imaging for preventive maintenance pays off. Continuous monitoring of technical equipment increases capital productivity, occupational safety and product quality.

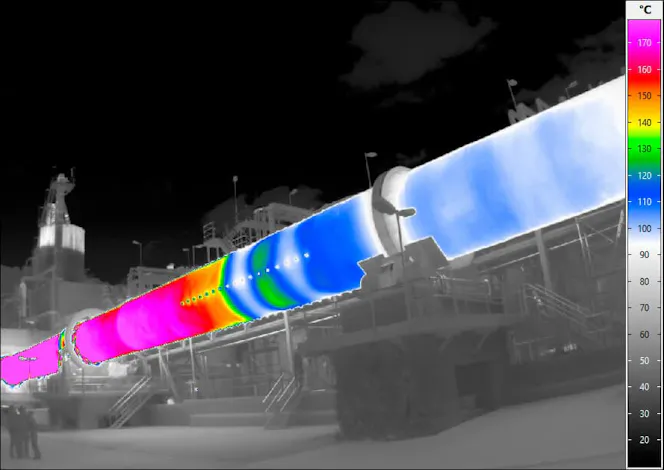

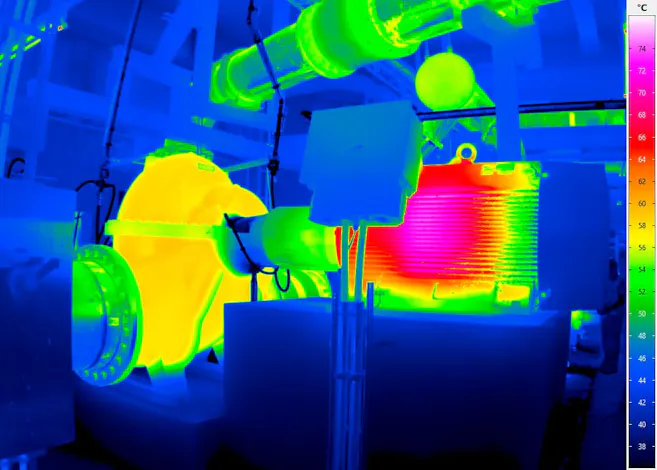

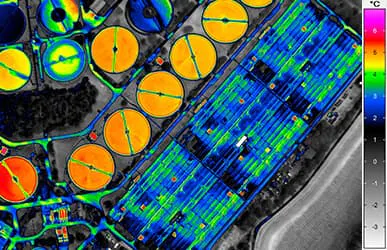

Thermal imaging allows inspection of a wide range of plant parameters during operation.

Efficient, 24/7 fully automated monitoring of plant technology and temperature-dependent processes

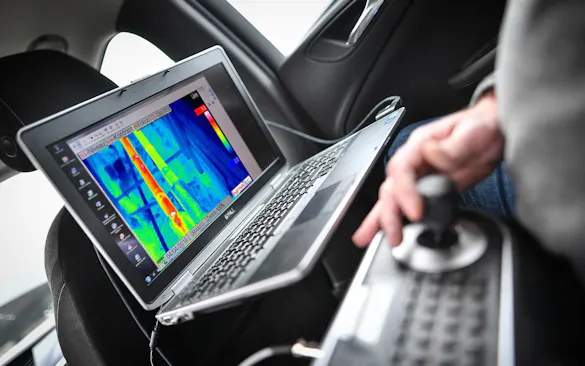

Imaging solution provides initial indications at the inspection site

Automatic warning and alarm when critical temperatures are reached

Simple and reliable tracking of plant status over time using stored data

Reduction in maintenance costs

Thermography: Reliable and Flexible for Inspection Systems of Plants in Continuous Operation

Increasing investment costs and the growing interconnection of production facilities place high demands on the reliability and service life of technical equipment. Condition-based maintenance based on continuous monitoring of the plant makes a decisive contribution towards that. Early detection of deviations and critical conditions also ensures high product quality and higher production throughput. Last but not least, permanent monitoring contributes to lower energy consumption and greater occupational safety.

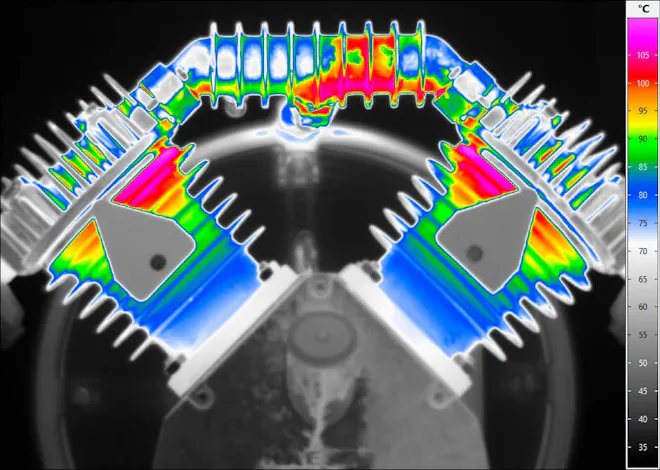

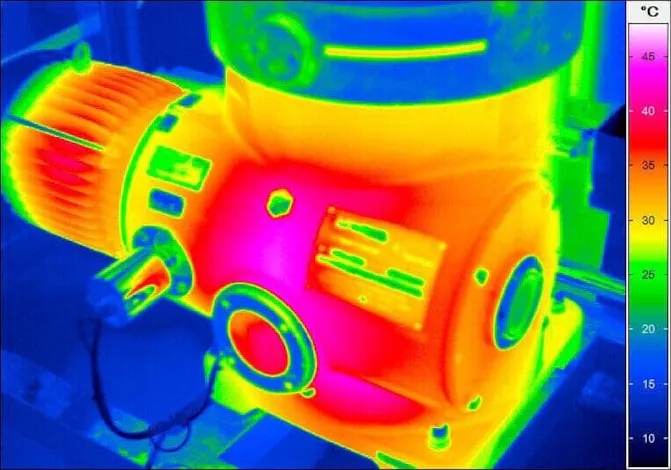

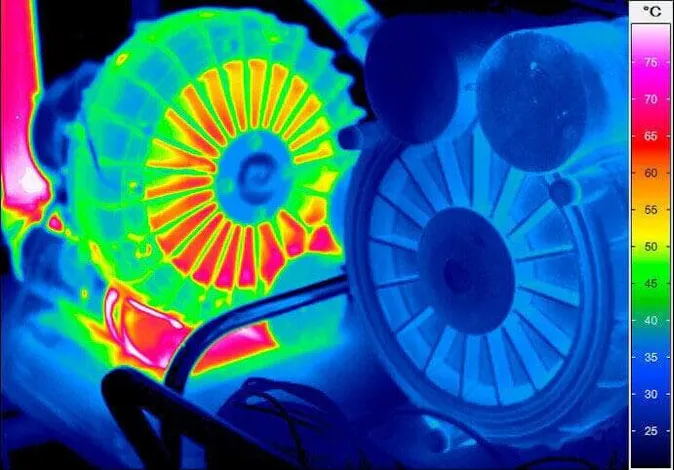

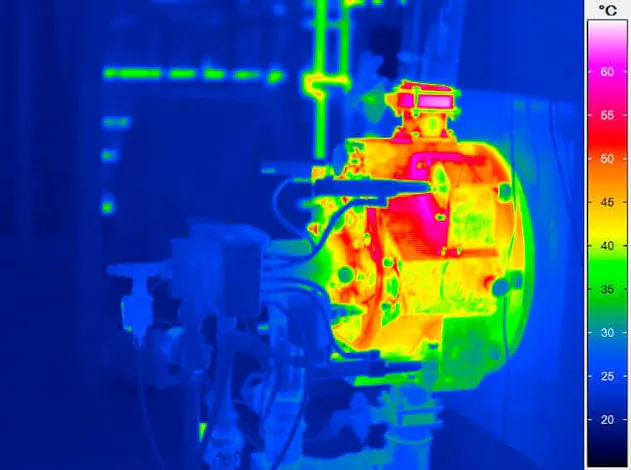

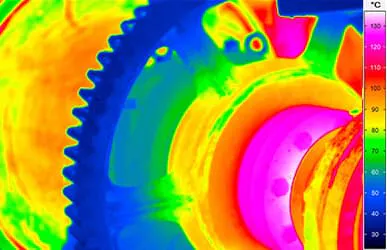

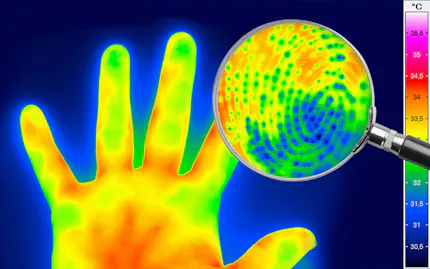

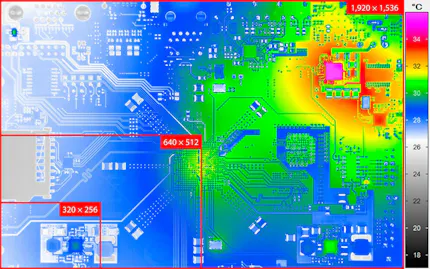

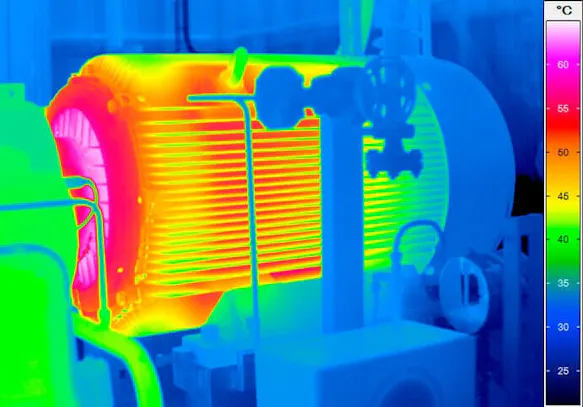

Thermal imaging as a method of preventive maintenance detects a wide range of fault sources associated with thermal changes:

increased resistance due to defects in electronics,

excessive friction on moving machine parts or

leaks in heat exchangers.

The measurement method thus makes a major contribution to the success of manufacturing company.

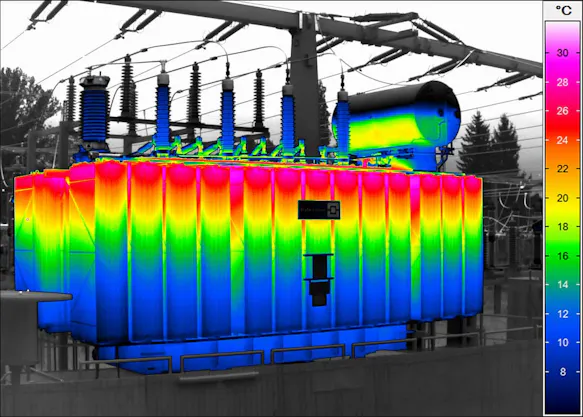

An Infrared Camera Allows Efficient Plant Inspection During Operation

A key advantage of preventive maintenance with an infrared camera systems is the ability to perform contactless temperature measurement. This means that thermographic inspections can be carried out during operation because they do not affect the performance of the system and do not require any interruption to the production process. In addition, the personnel responsible for monitoring are not exposed to any risks during the inspection, as they do not have to be in the vicinity of the system.

The visual representation of the temperature distribution provides a quick overview of the current system status at any time. If temperature thresholds are exceeded, an alarm is automatically triggered, enabling rapid intervention. Stored thermography data also allows the system status to be continuously monitored without any problems, enabling maintenance to be carried out at the best possible time.

Ensuring Machine Health

The condition of an individual machine is often described using the term machine health. Various methods are used to reliably assess the health of a machine, that is, to detect wear, malfunctions, or impending failures in a timely manner. For example, vibrations can be measured, the volume and characteristic sound of a machine can be recorded, electrical power consumption can be logged, or temperatures and temperature curves on particularly highly stressed machine parts can be monitored using infrared cameras.

Contactless temperature measurement in particular offers significant and readily exploitable potential when it comes to machine health: if critical temperature trends or overheating are detected at an early stage, preventive countermeasures can be taken before major damage occurs. Targeted cooling measures or the replacement of damaged parts help ensure that machine downtime is minimized.

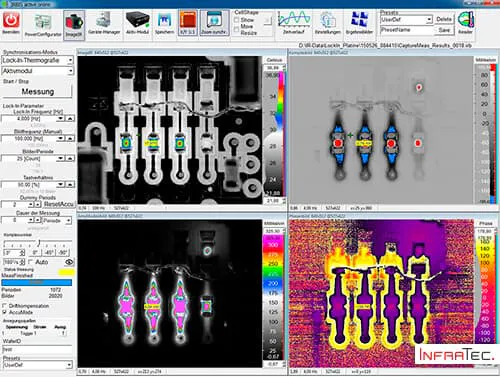

The use of artificial intelligence is particularly well suited to the context of preventive maintenance and machine health: AI-based evaluation of the condition data obtained allows patterns and potential deviations from them to be detected more quickly.

Online Events On Demand

Thermography for Industrial Automation

Efficient quality control through fast, contactless temperature measurement during ongoing production

Flexible system solutions from modular components to fully customized turnkey setups

Integrated software for automated evaluation, documentation, and triggering of follow-up processes

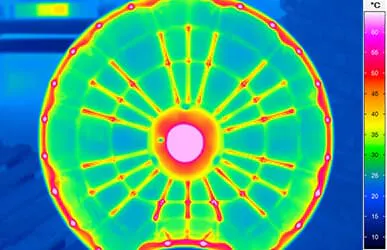

Applications for Thermal Imaging on Wind Power Systems

General information about infrared thermography and presentation of different infrared camera techniques

Monitoring wind turbine power plants by (passive) thermography

Principle & methods of active thermography and examples

Technical Lecture “Inspection of Wind Turbine Blades with Ground-based Passive Thermography” from Michael Stamm, Federal Institute for Materials Research and Testing (BAM)

Would You Like to Know More?

It is not unusual for tasks to be associated with special requirements. Discuss your specific application needs with our specialists, receive further technical information or learn more about our additional services.

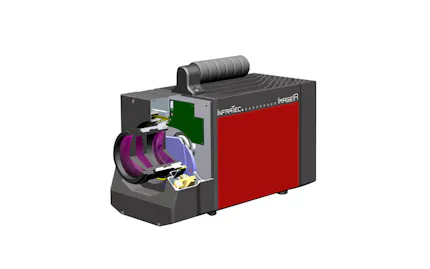

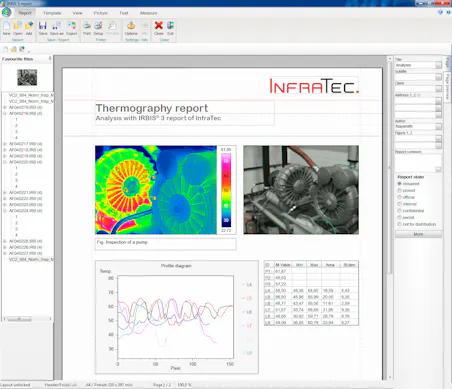

Fast Reporting of Essential Inspection Results

A big advantage of infrared camera systems for companies is the easy handling and the low maintenance needs. Especially the cameras of the VarioCAM® HD series come with a rugged design making them most suitable for usage in rough industrial environments. The thermographic software IRBIS® 3 provides efficient analysis of thermographic data and reporting for the transfer of crucial inspection results.