Thermography in Mechanics

Precise Inspection of Mechanical Components with Infrared Cameras

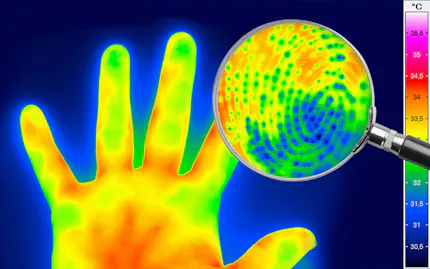

Visualize mechanical stress: Thermography detects friction, tension, and compression through temperature changes

Early fault detection: High-resolution thermal imaging reveals issues before visible damage occurs

Analyze fast-moving processes: High frame rates capture dynamic motion in real time

Engineered for tough environments: IP67-rated cameras with optional protection for extreme conditions

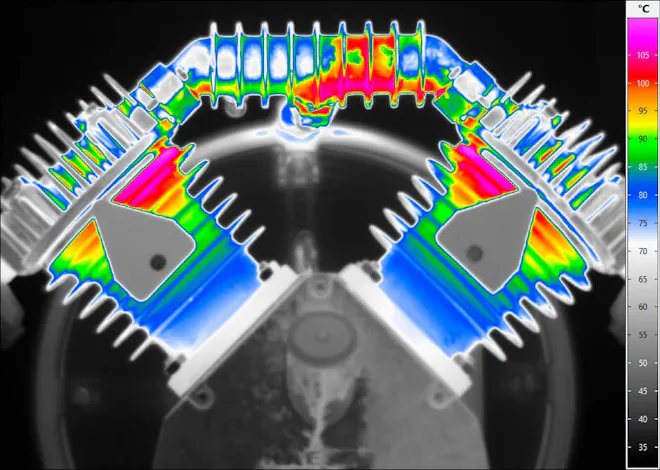

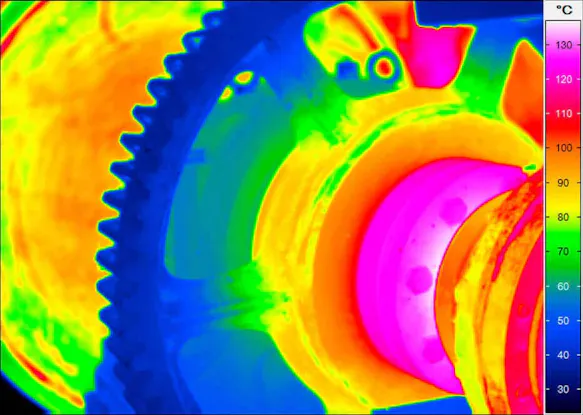

Acquisition of Temperature Changes Caused by Draft, Pressure or Friction During Operation

Mechanical components get loaded by pressure, draft or friction during operations. Those load types will all result in an increased temperature. Like this the running of a spindle will result in friction even though being well lubricated. If the spindle is not well positioned the friction will even increase. Infrared camera systems provide a fast overview of the status of the operation long before indications can be seen without such a device.

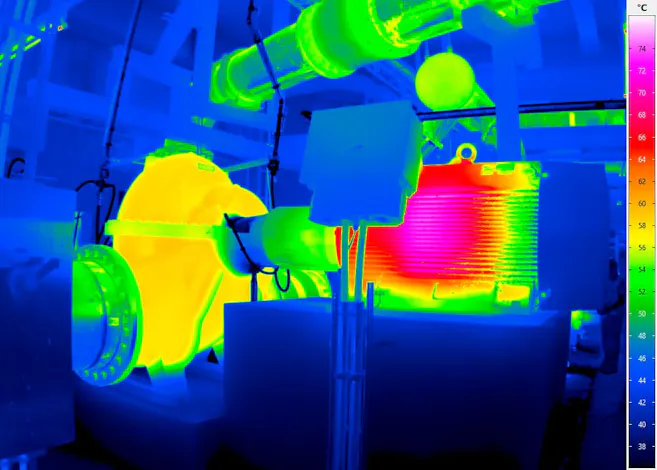

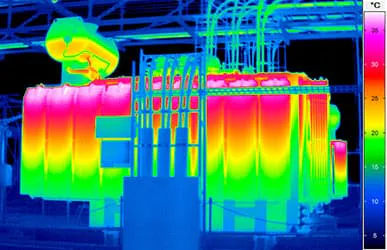

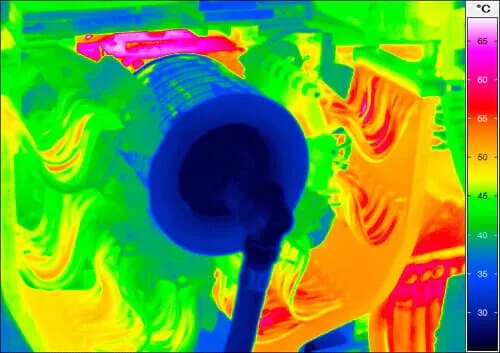

Thermographic Inspections from a Safe Distance

Thermography offers a particular advantage in the preventive maintenance of mechanical systems and plant insepection thanks to its non-contact temperature measurement. In this way, it makes an important contribution to maintaining machine health, enabling continuous monitoring of the machine condition. Maintenance personnel can often carry out inspections from outside the hazard zone of rotating or otherwise rapidly moving machine parts.

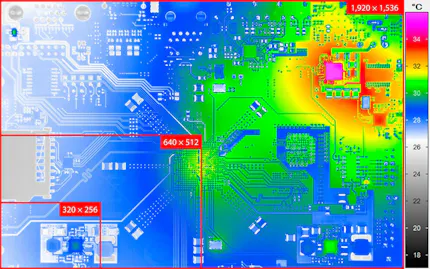

Inspection is further facilitated by the fact that the thermal imaging camera itself provides a visual overview of the inspection situation. This allows thermal irregularities to be detected and assessed at an early stage – a key advantage for condition-based maintenance concepts. In critical situations, initial measures can be taken on site even before a detailed analysis has been completed. Predefined temperature thresholds for alarm triggering and other customizable configurations support maintenance teams in efficiently integrating thermal imaging cameras into their strategies for ensuring machine availability.

Fast Movements Can Be Resolved by Infrared Camera Systems with High Frame Rates

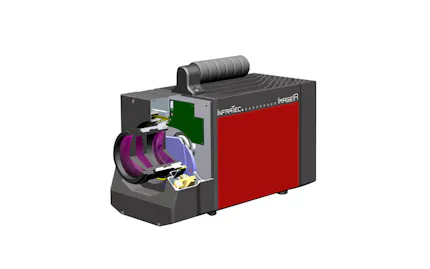

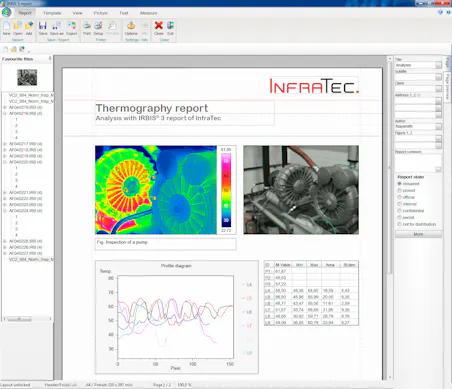

Many mechanical movements run at high speeds. Infrared camera systems should be able to resolve such movements to selectively detect faults. Frame rates of up to 240 Hz in full frame mode of the inspection cameras out of the VarioCAM® High Definition series series or up to 105,000 Hz with the ImageIR® camera series provide with exactly this advantage. Combined with sequence analysis tools of the thermographic software IRBIS® 3 smallest faults can be found right in the moment of emergence and subsequently those faults can be eliminated.

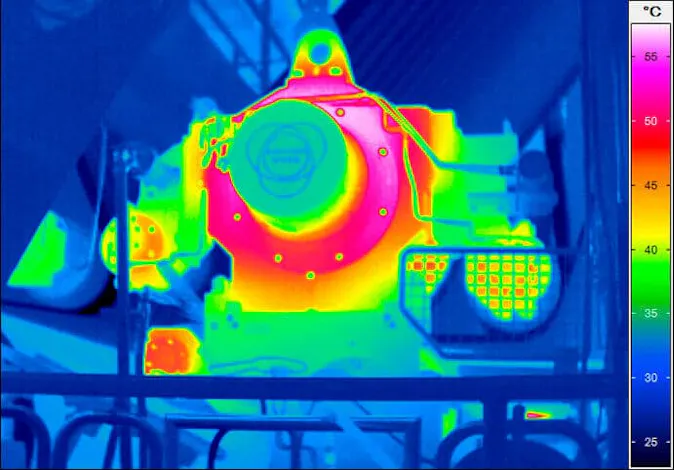

Thermography Brake Test Bench and Tyre Test Bench

The long-life fatigue strength and wearout are important characteristics of mechanical components. Manufacturers test these with certified procedures. Thermal measuring can be the decisive relief needed for evaluations under stress.

Quick data acquisition with InfraTec's high-end systems

Powerful evaluation software IRBIS® 3 rotate available

Online Events On Demand

Efficient Material Testing – Non-destructive and Contactless

Theoretical background – mechanical force, stress and temperature Methods for analysis

Examples from practice with application samples – elastic periodical load test and fatigue test

Short overview about InfraTec products

Complementary technical lecture

"Contribution of Thermoelastic Stress Analysis in mechanics of materials and structures: some illustrations" from Prof. Vincent Le Saux, École Nationale Supérieure de Techniques Avancées Bretagne

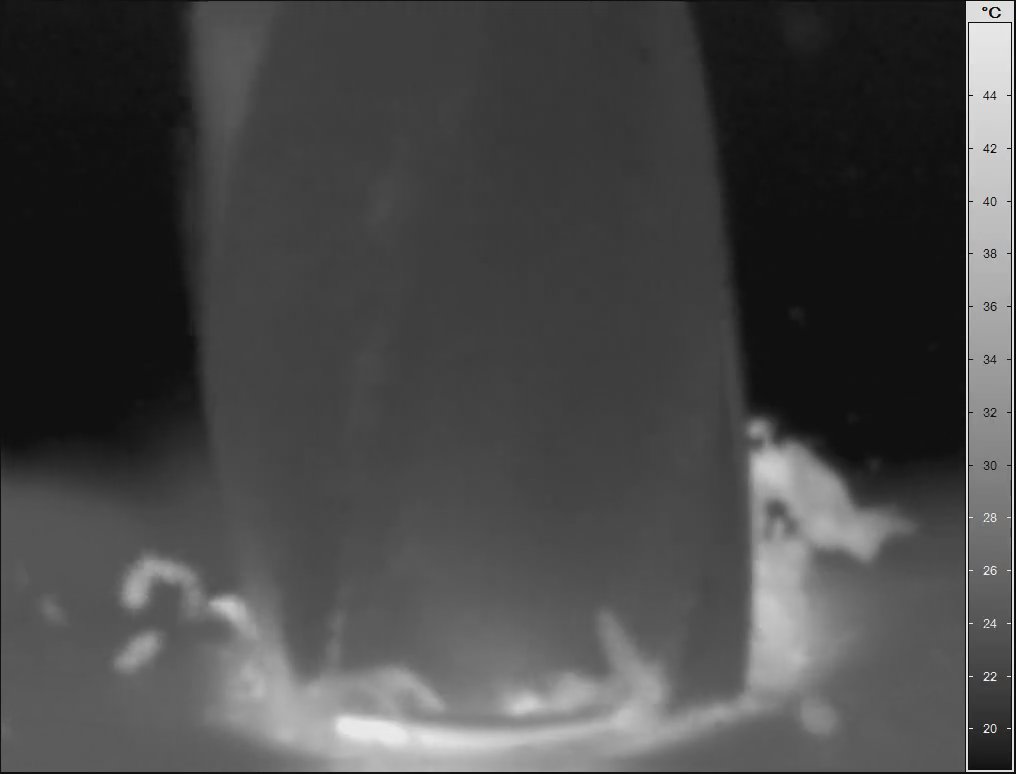

Flow Analysis Using Thermal Imaging

General information about infrared thermography and presentation of different infrared camera techniques

Presentation of different flow types and how to measure them with thermography

Demonstration of different application possibilities, e.g.: aerodynamic optimisation, heat management industry, environmental research, geological research

Technical lecture “A Non-Intrusive Particle Temperature Extraction Methodology Using Infrared and Visible-Image Sequences for High-Temperature Particle Plumes”, Jesus D. Ortega, PhD, MSME, MBA / Anderson School of Business and School of Engineering, The University of New Mexico, USA

Would You Like to Know More?

It is not unusual for tasks to be associated with special requirements. Discuss your specific application needs with our specialists, receive further technical information or learn more about our additional services.

Fast Reporting of Essential Inspection Results

A big advantage of infrared camera systems for companies is the easy handling and the low maintenance needs. Especially the cameras of the VarioCAM® HD series come with a rugged design making them most suitable for usage in rough industrial environments. The thermographic software IRBIS® 3 provides efficient analysis of thermographic data and reporting for the transfer of crucial inspection results.