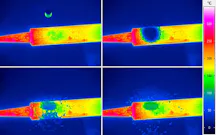

Subwindowing

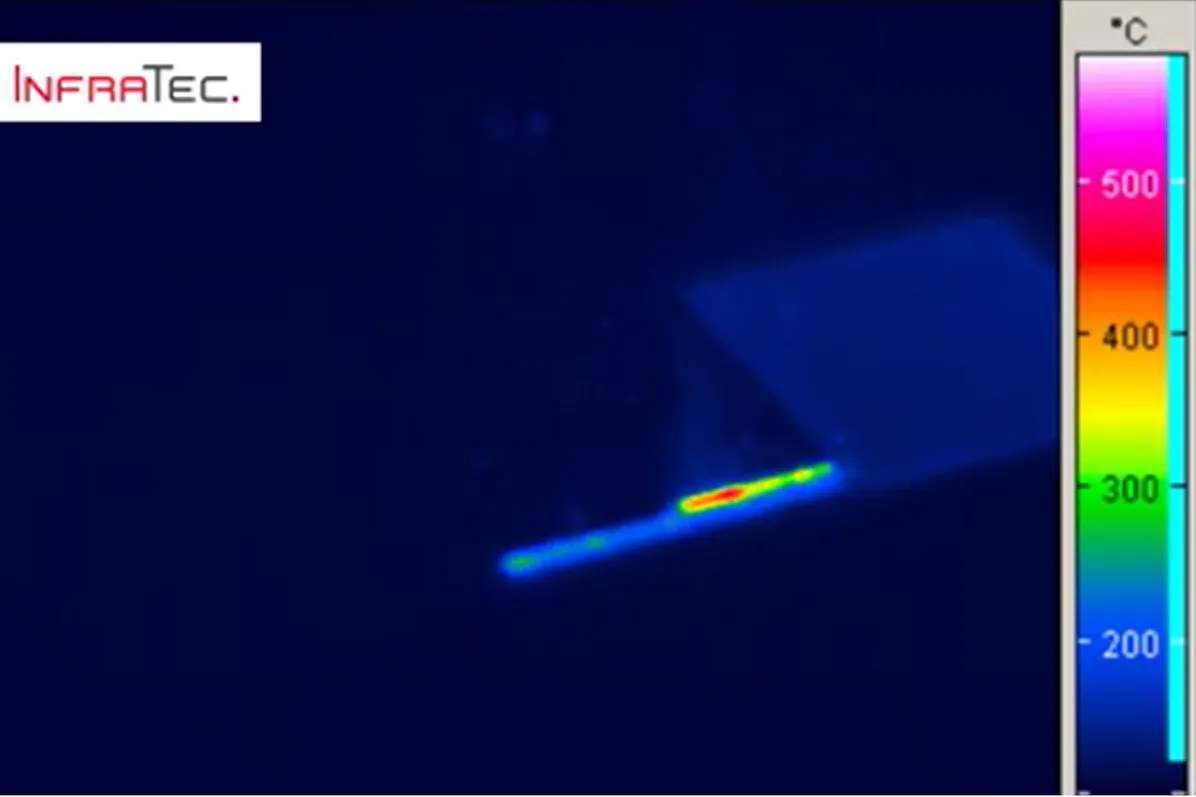

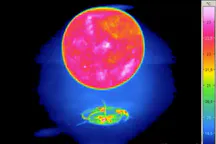

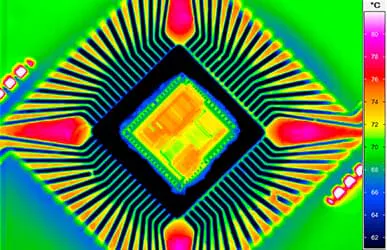

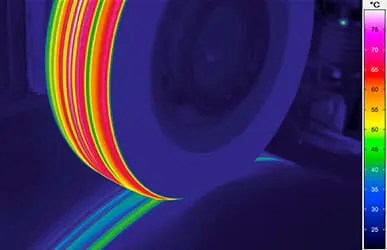

Window Mode of ImageIR® – Up to 105,000 Hz

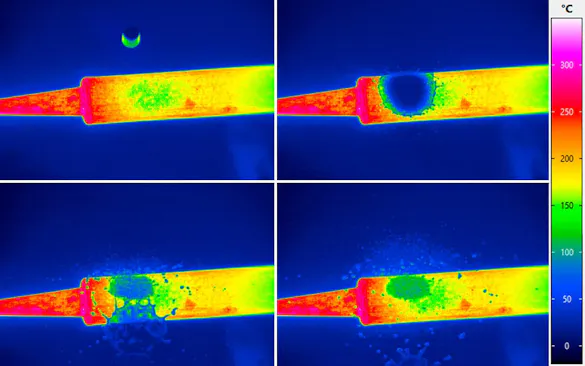

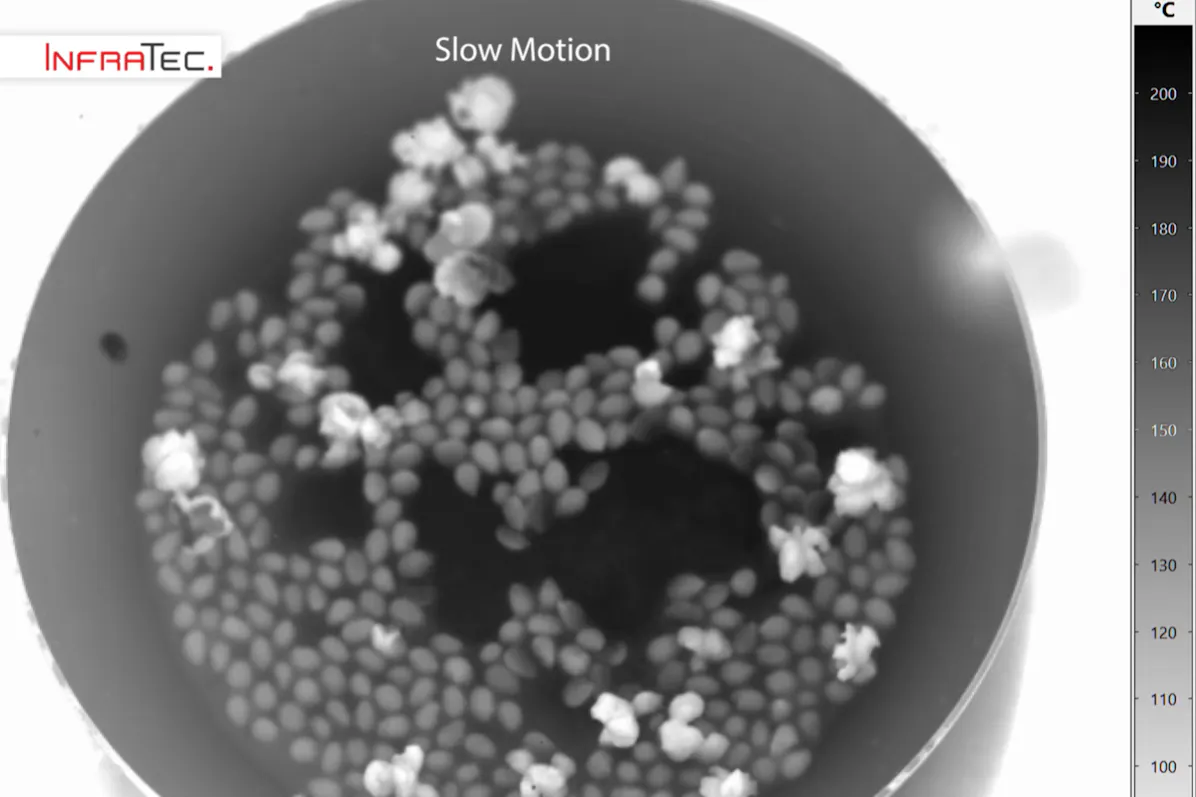

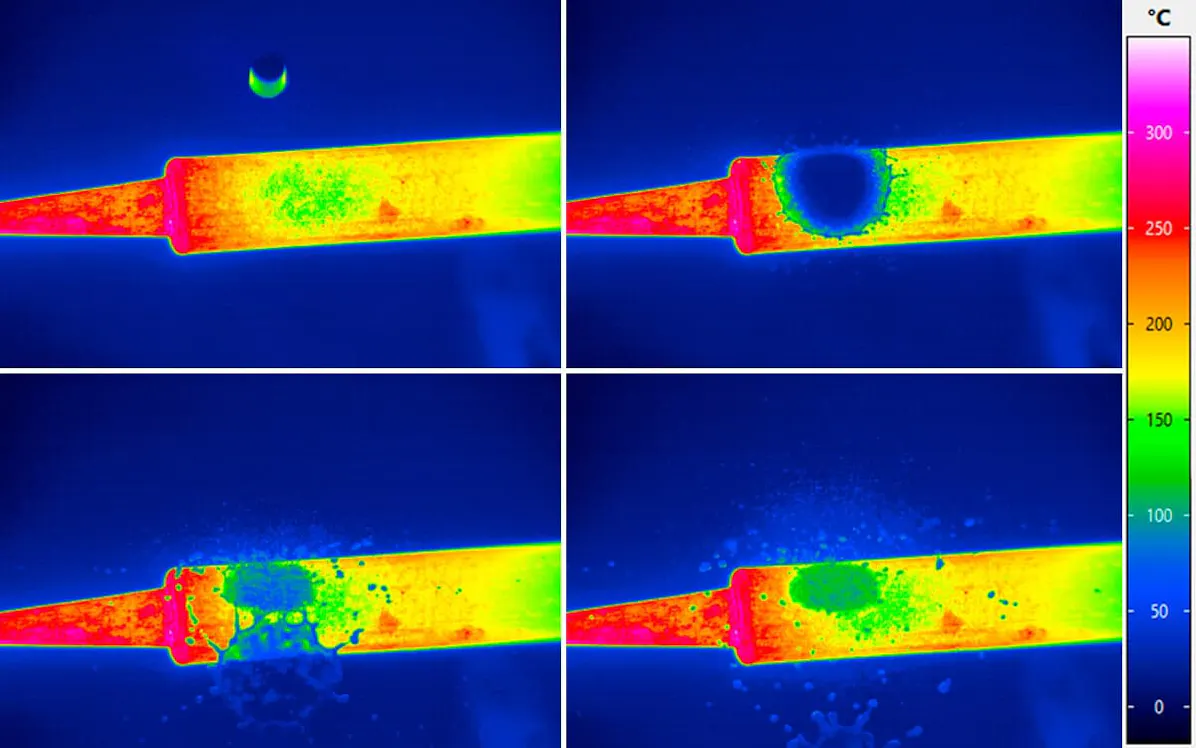

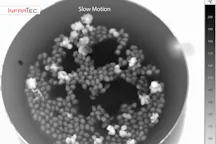

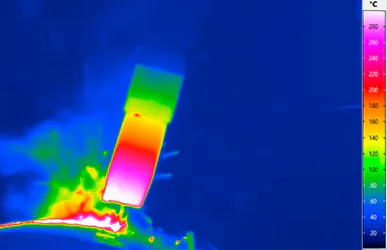

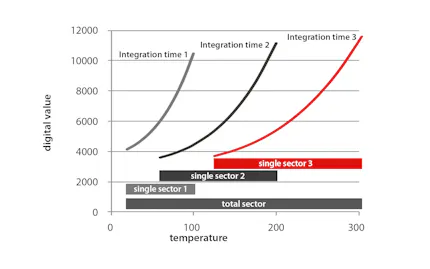

The ImageIR® can be operated in full, half, quarter and sub mode. With the camera control software, it is possible to use the extended subwindowing function. Using click-and-drag, freely definable sections can be set up quickly and conveniently. Subwindow image frequencies of up to 105,000 Hz can thus be achieved.

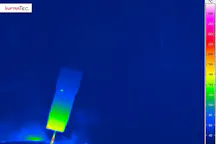

Overview of Benefits of High-Speed-Thermography with ImageIR®

High-speed measurement up to 105,000 Hz

Snapshot detectors and complementary components provide for highest measurement speed

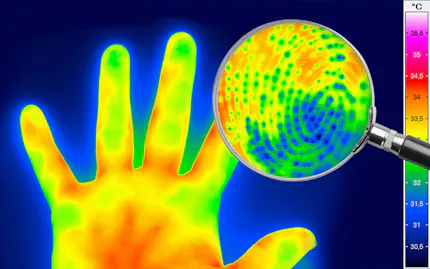

Fully radiometric real-time sequences with up to 16 bit data depth

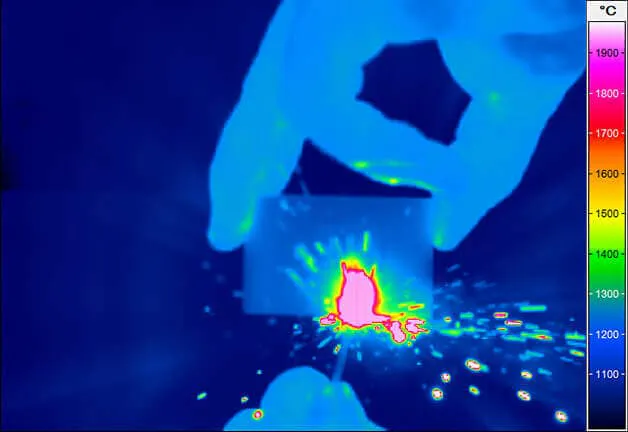

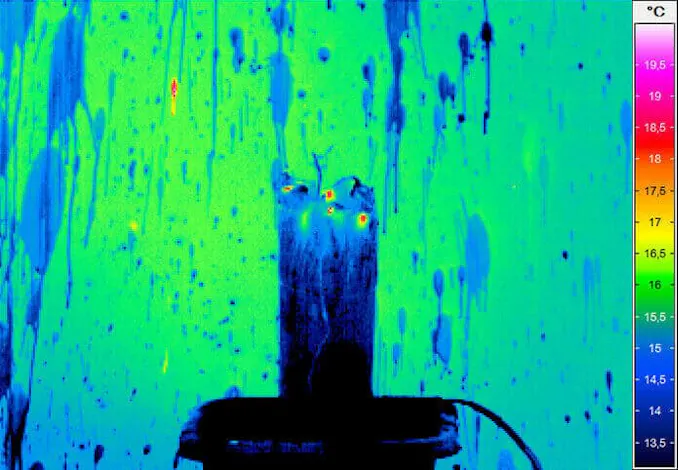

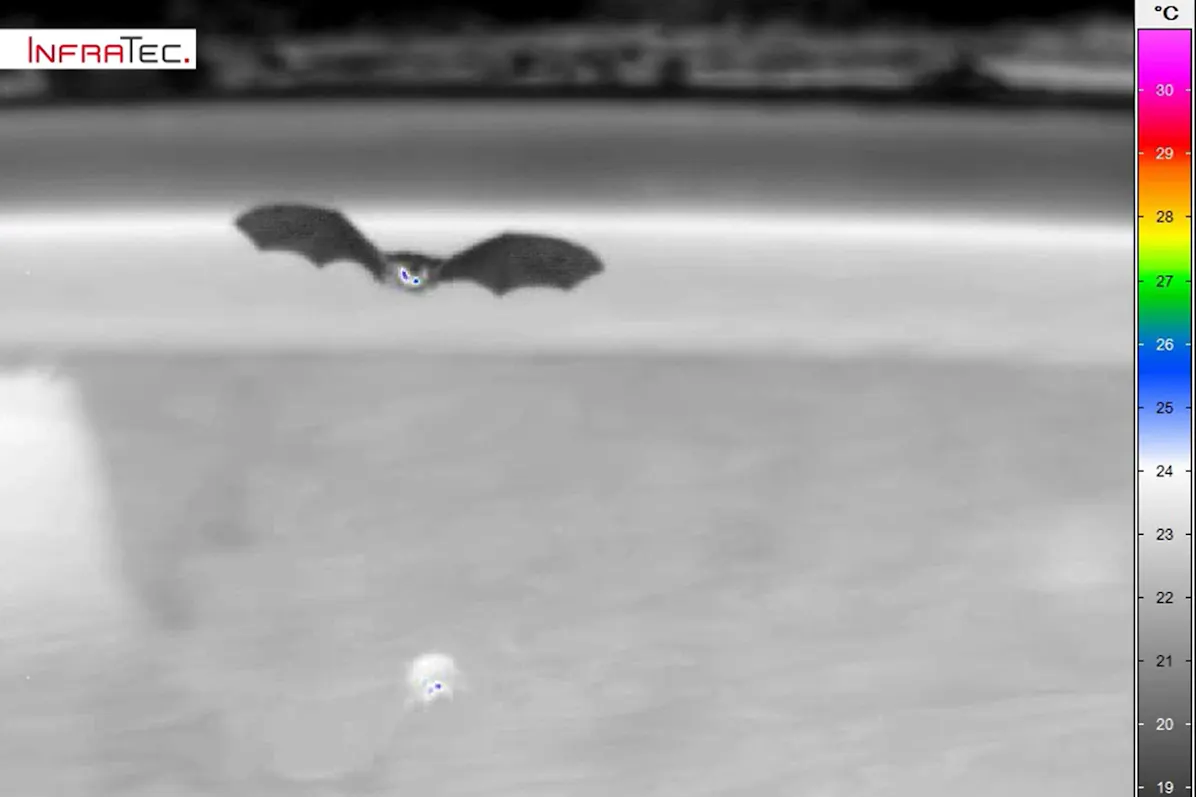

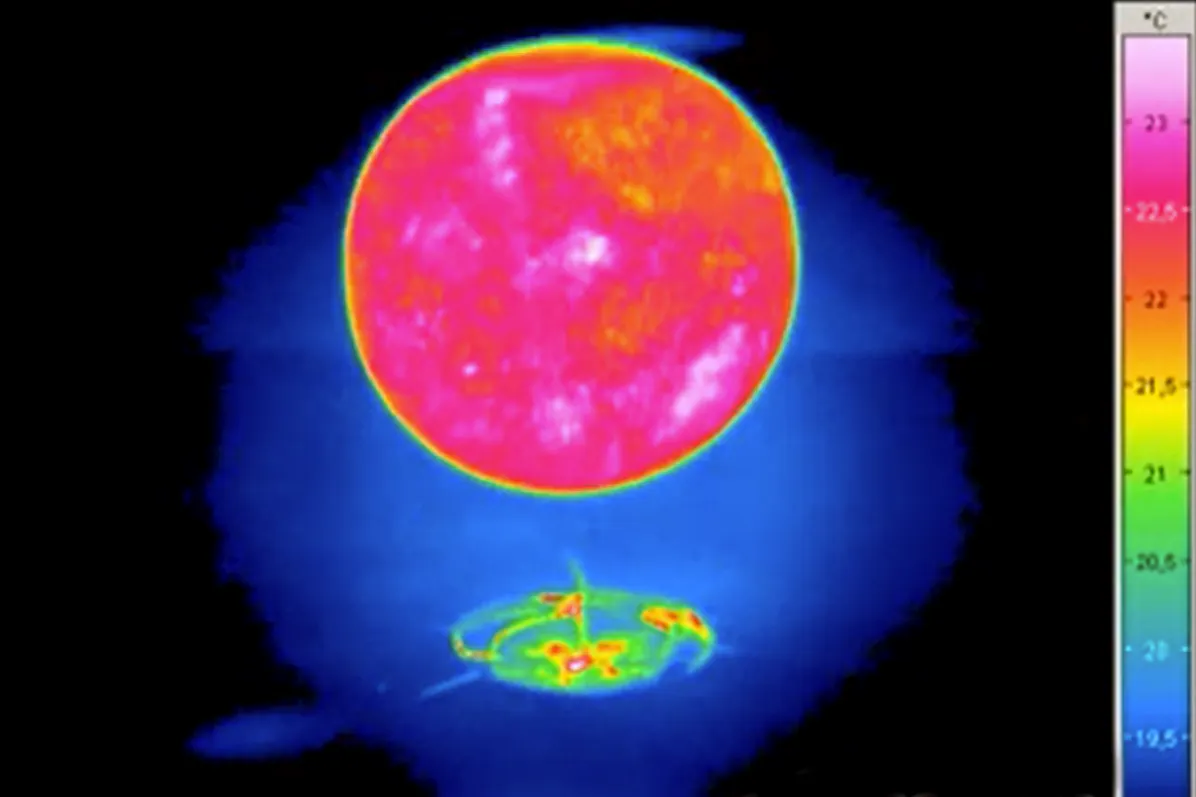

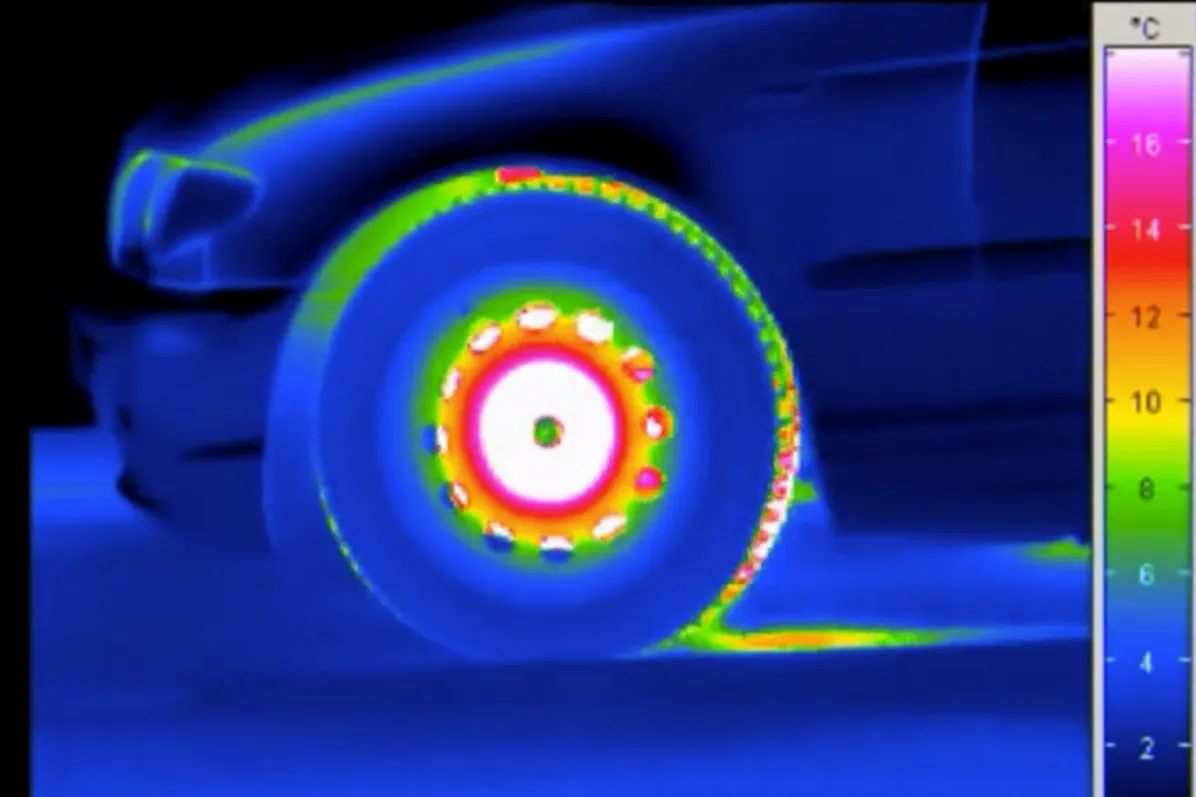

Capture of extremely rapid temperature and motion sequences

High-speed capture of radiometric thermal images on Notebook/PC via 10 GigE interface

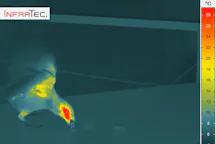

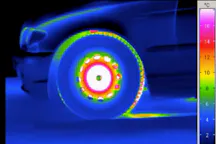

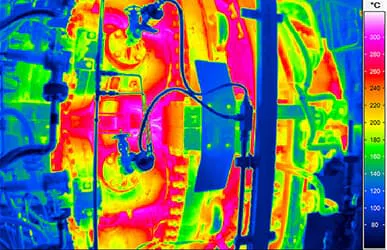

High-speed Measurement with VarioCAM® High Definition

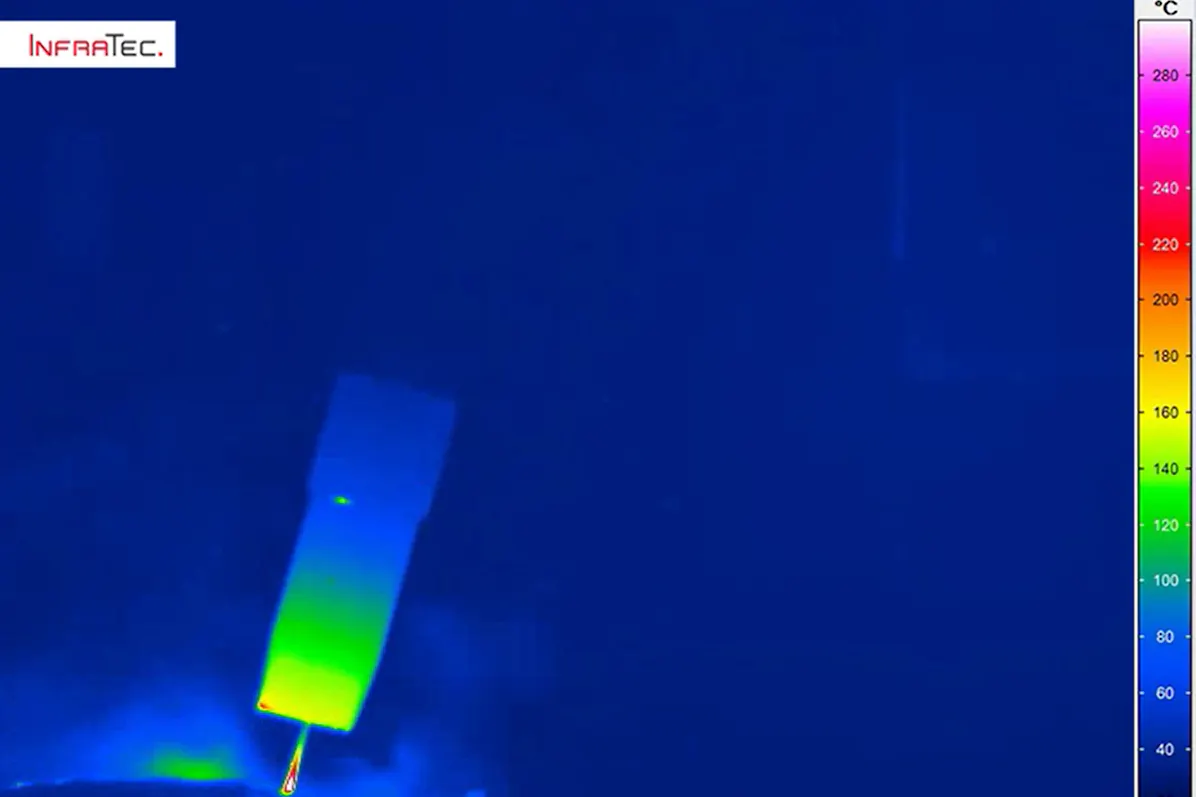

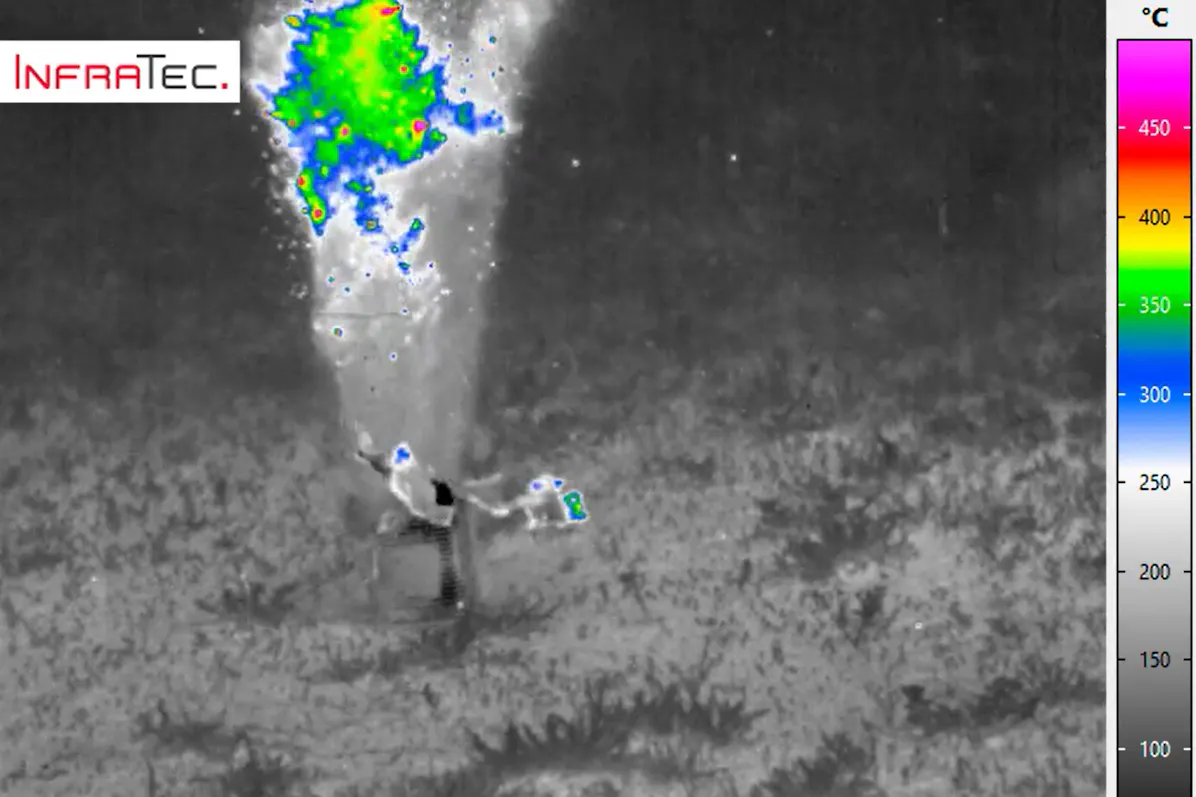

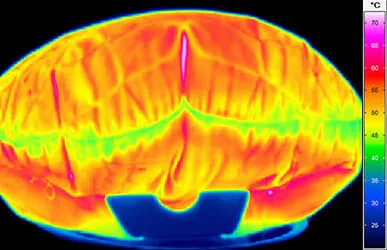

The infrared camera VarioCAM® High Definition enables the usage of the sub-frame mode (sub-windowing) for rapid temperature changes. This means thermographic sequences with refresh rates of up to 240 Hz can be created with the camera series VarioCAM® HD. A defined sub-frame of the detector is picked out to achieve these extremely high refresh rates.

Besides the storage of thermographic sequences via GigE interface with the thermography software IRBIS® 3 online, there is the option to save fully radiometric sequences with 16 bit data depth directly in the camera memory, to analyse there or transmit to the software IRBIS® 3. No measurement information is lost with high-speed online measurement. Data can be analysed in detail and subsequently processes.

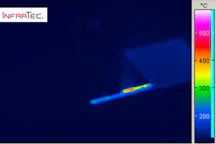

Overview of Benefits of High-Speed Measurement with VarioCAM® High Definition

High-speed measurement up to 240 Hz

Fully radiometric real-time sequences with 16 bit data depth

Capture of extremely rapid temperature and motion sequences

High-speed capture of radiometric thermal images on Notebook/PC via GigE interface