Thermography in Glass Industry

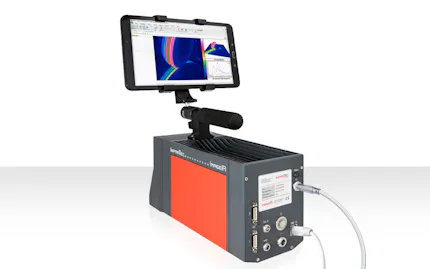

Make your processes more efficient by using an infared camera in the glass industry. InfraTec offers advanced infrared measuring instrument.

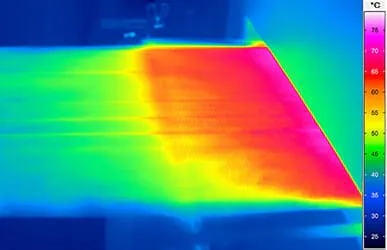

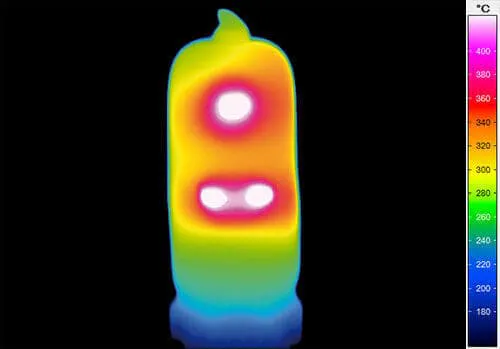

Generally, glass appears to be non-transparent in the infrared spectrum

Spectral thermography allows measurements on and through glass

Motorised filter wheel facilitates fast filter change

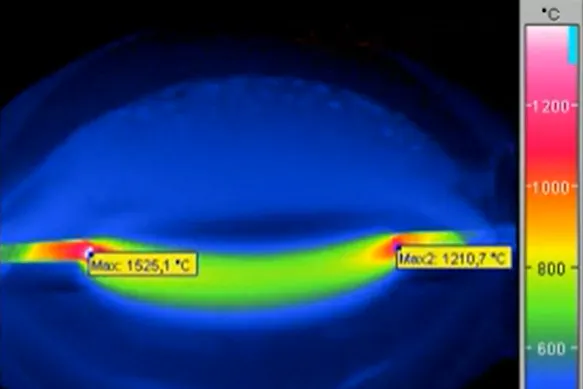

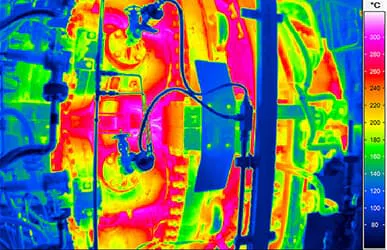

Attention to Sources of Error On-Glass Measurements

In contrast to the visible light spectrum, glass – being looked at with an infrared camera – generally appears in a non-transparent way, since its transmission factor is very low in the infrared range. Therefore, it is mostly possible to determine the temperature of glass without making specific arrangements, even though in case of thinner glass layers and high temperatures behind glass, radiation of transmission can lead to distorted thermographic measurement results. The glass temperature then would be disproportionally high.

Would You Like to Know More?

It is not unusual for tasks to be associated with special requirements. Discuss your specific application needs with our specialists, receive further technical information or learn more about our additional services.

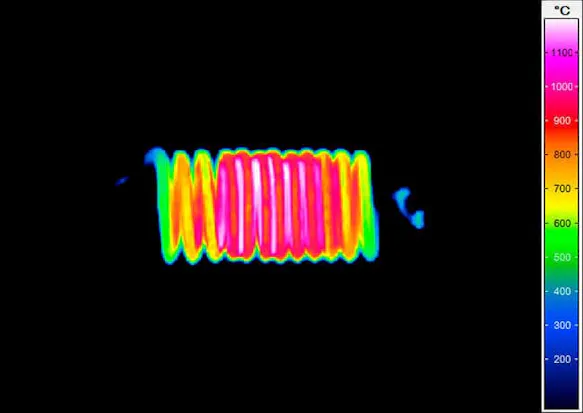

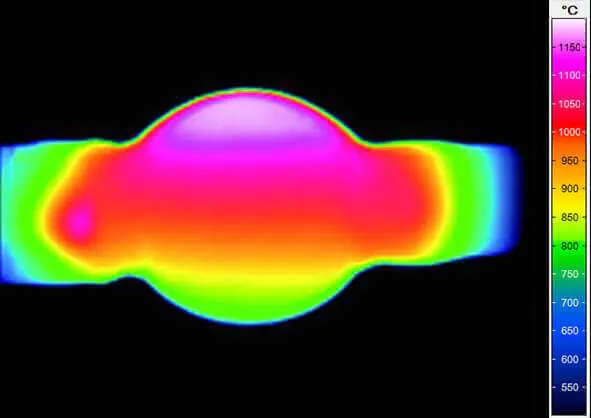

Precise Glass Measurement with Thermography Through Spectral Filters

The problem of glass measurement can be solved by applying InfraTec’s infrared camera systems of its high-end camera series ImageIR®. These are possible to be equipped with spectral filters being deployed in a filter wheel. Filters will be individually adjusted according to the specific glass of the customers. On the one hand, these filters allow measuring the surface temperature of glass without any impact of the transmission radiation of objects behind glass. On the other hand, measurements of objects with high temperature behind glass can be carried out without having an influence on the glass surface temperature. Since the infrared camera’s filter wheel is power-driven and remotely controllable, switching between both modes can be ensued by a keystroke at the control computer.