Choose the Optimum Camera Setting for Every Measurement Situation with HighSense

Different measurement scenarios often require temperature measurement ranges or integration times that vary from the initial factory calibration and are individually adjusted. Usually the calibration is invalid as a result of such adjustments and the thermographic camera no longer provides any accurate temperature measurements. HighSense opens up an alternative. Thanks to this innovative function, the measurement accuracy of the cameras is also preserved when integration times or the measurement ranges are changed. With maximum flexibility users also save costs, for example, by avoiding additional application-specific special calibrations.

This is How Users Set up Individual Customized Temperature Measurement Ranges

HighSense enhances the existing factory calibration of the thermographic camera. It enables the possibility of setting up individual customized temperature measurement ranges in two different ways.

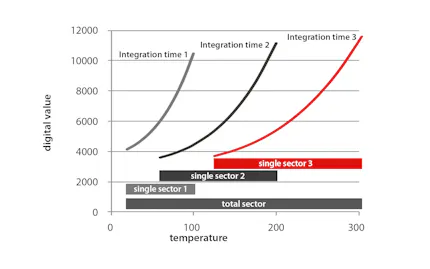

The first one allows for the selection of a desired integration time. After entering the integration time via the intuitive software interface, the resulting temperature measurement range is calculated automatically and can be used for accurate measurements. At the same time, the selected lens as well as neutral density filters or spectral filters are also taken into account.

The second way addresses the issue of the temperature measurement range. This can be specified by defining an upper and lower limit. Afterwards, the appropriate integration time is calculated again to achieve the optimum signal-to-noise ratio and stored as setting parameter for the planned measurement task. Depending on whether a particularly high thermal sensitivity or the maximum possible frame rate is paramount – with the appropriate adjustment of integration times and the resultant automatically generated temperature measurement ranges the HighSense feature offers considerably more flexibility in order to optimally fulfil the measuring tasks at hand.

No Additional Calibration of Individual Sub-frames

In addition, the calibration of individual sub-frames is no longer necessary. The adjustment of the calibration data, which applies to these frames, takes place automatically as well. On this basis, accurate temperature measurement values are also provided for the corresponding window modes. Thus, the choice of the temperature measurement range as well as the integration time does not depend on whether the image should result in full-frame mode or in sub-frame mode, which can be used to achieve a higher frame rate.

Conveniently Store Settings for Recurring Tasks

Thanks to HighSense, users of the ImageIR® have the option to set up individual measurement ranges based on the factory calibration, which are best suited to the task at hand. The software also offers the possibility of storing a multitude of such ranges in a clearly visible way. Individually named and permanently stored, the user can access these settings quickly. The same holds true when it comes to changing, renaming and deleting the profiles.

HighSense is available for various camera models of the ImageIR® series. Systems that have already been delivered can optionally be enhanced by this function.

Would You Like to Know More?

It is not unusual for tasks to be associated with special requirements. Discuss your specific application needs with our specialists, receive further technical information or learn more about our additional services.