ImageIR® 8300 hp

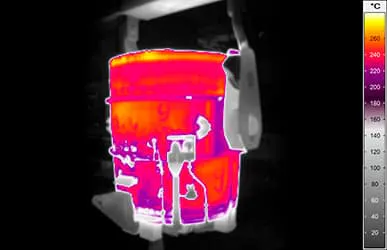

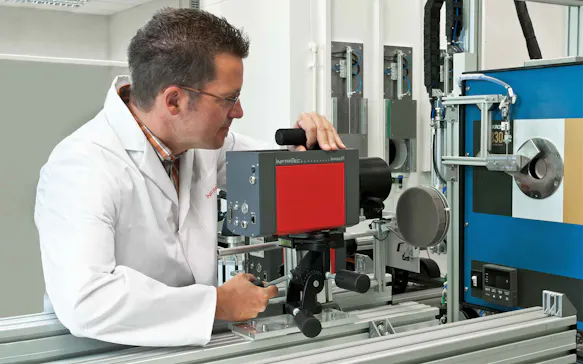

The infrared camera ImageIR® 8300 hp of the high-end camera series ImageIR® provides the requirements for high-speed thermography at the top level.

Full-frame rate up to 355 Hz in the format (640 × 512) IR pixels

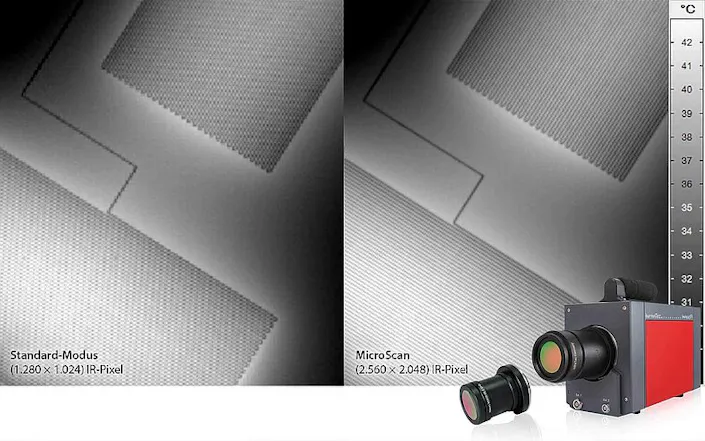

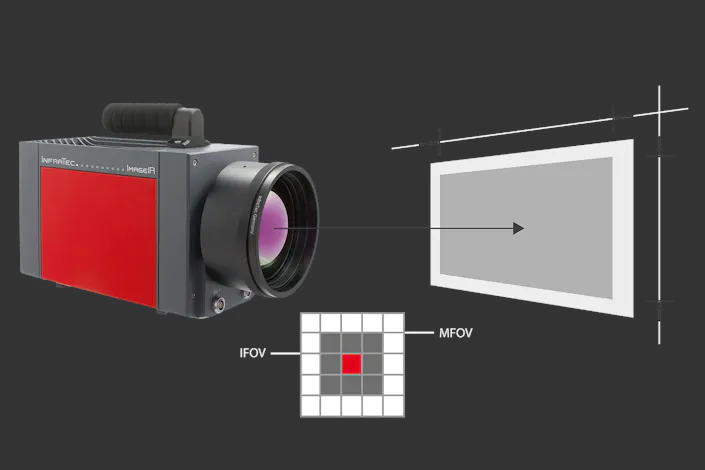

Opto-mechanical MicroScan with (1,280 × 1,024) IR pixels

Outstanding thermal resolution better than 20 mK

Integrated trigger interface guarantees a repeatable high-precision triggering of quick procedures

Large detector enables highest sensivity

(1,280 × 1,024) IR pixels by genuine camera hardware

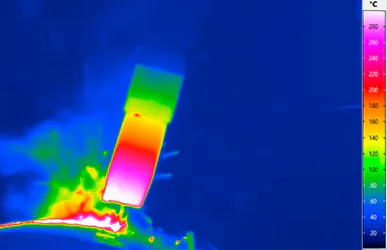

Analysis of extreme temperature changes and gradients in full frame

Highly accurate and repeatable measurements

High-speed, long-distance interference proof data transmission

Flexible setting of temperature measurement ranges/integration times beyond calibration ranges

Facilitates the analysis of objects with extreme temperature gradients

Next generation of Infrared Detector Interface Boosts Camera Full-frame Rate

The new ImageIR® 8300 hp with InSb-MWIR focal-plane array photon detector of the latest generation with (640 x 512) IR pixel now allows 355 Hz full-frame rate. Thus, ImageIR® 8300 hp reaches a three times higher frame rate in full frame mode than previous camera systems in this perfomance category. In combination with ultra-short integration times ultrafast industrial processes or research tasks can be recorded and analysed with maximum detail.

The infrared camera saves images with following frame rates:

Full frame: up to 355 Hz

Half frame: up to 670 Hz

Quarter frame: up to 1,200 Hz

Line: up to 5,000 Hz

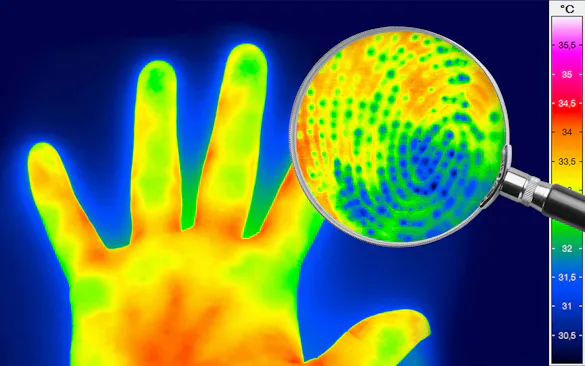

Like all camera models of this series ImageIR® 8300 hp reaches an outstanding thermal resolution of better than 0.025 K (25 mK, typically 20 mK) and was developed for most demanding operations in research and development and process monitoring fields. Its modular structure consisting of the optical-, detector- and interface section, makes the camera easily compatible to the related applications and for tailored configurations.

An integrated trigger interface guarantees a repeatable high-precision triggering of quick procedures. Two configurable digital in- and outputs serve as control ports for the camera or as generator of digital control signals for external devices.

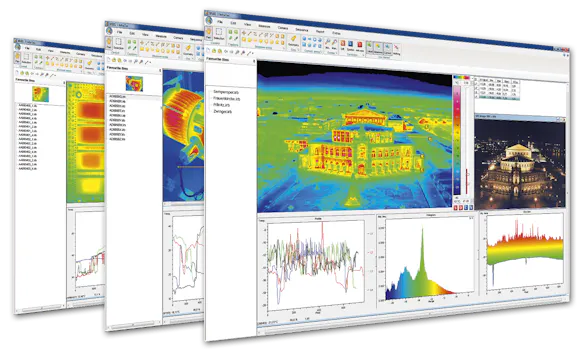

In combination with InfraTec´s thermographic evaluation software IRBIS® 3 professional, ImageIR® 8300 hp sets new standards as an efficient high-performance tool for demanding thermography studies.

10 GigE Interface for a Strong Increase in Output

The new 1 Gigabit Ethernet interface of the high-end camera series ImageIR® opens this extremely fast transmission standard with a NIC specially developed by InfraTec. This works with optical or electrical transceiver modules that are easy to change and are called SFP+. For all models of the ImageIR® 8300 hp with their (640 × 480) IR pixel detectors this leads to a transfer rate in the full frame mode up to 355 Hz. Users can store large quantities of data to a computer easily and reliably.

Different 10 GigE fiber SFP+ transceivers allow transmission ranges of up to ten kilometers with the same low sensitivity to electromagnetic interference. A corresponding standard SFP ensures backward compatibility with the conventional GigE interface. This combination allows the ease of use of the cameras with the new 10 Gigabit Ethernet interface in existing systems - though at a reduced transmission rate.

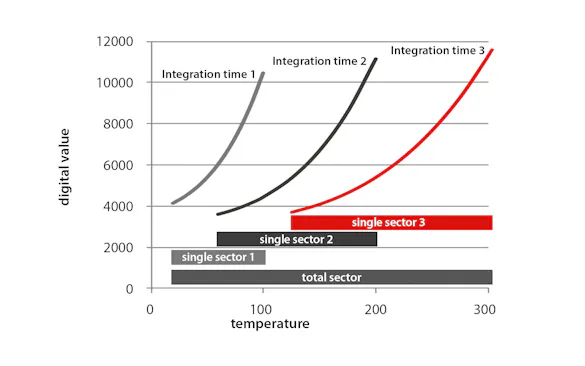

HighSense – Always the Optimal Camera Setting

Cameras of the ImageIR® series have a reliable factory calibration. Thanks to HighSense, ImageIR® users have the option of setting up individual temperature measuring ranges based on the factory calibration that best suit the respective task.

Depending on the measuring task, the required temperature range can be selected and the optimum integration time for this purpose is calculated – or one decides to proceed in reverse order. Thus, the calibration can be retained even in the case of changed integration times.

The software also offers the possibility of storing a large number of such areas clearly arranged. Individually named and permanently stored, the operator can quickly access them. The same applies to changing, renaming and deleting profiles. HighSense is available for different camera models of the ImageIR® series. This function can optionally be added to systems already delivered.

Download HDR White Paper

Download the HDR white paper to get further information how it works and what the benefits are.

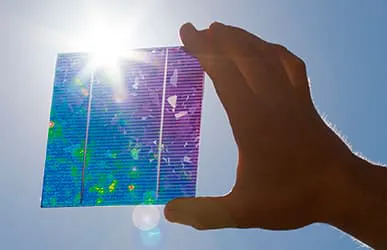

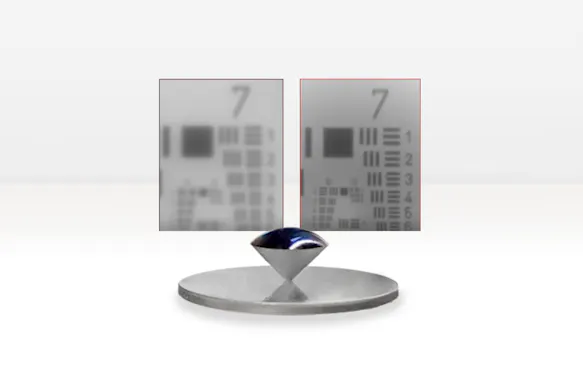

Solid Immersion Lens (SIL) for ImageIR®

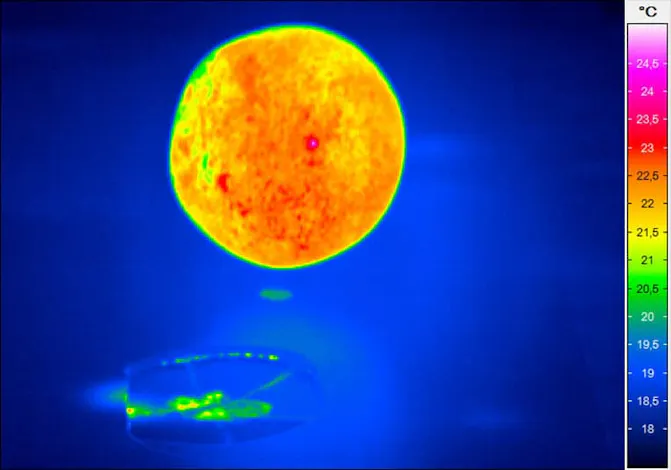

In order to make particularly small structures clearly visible, an infrared camera with a large detector format is suitable. In some cases, special measurement and testing tasks require a further increase in spatial resolution. In the field of micro-thermography, high-performance infrared microscopic lenses are used for this purpose. Their benefits can be further increased in conjunction with Solid Immersion Lenses (SIL). Mounted on the optics, these immersion media significantly improve the resolution of even the smallest structures in the µm range.

Technical Specifications of ImageIR® 8300 hp

| Spectral range | MCT: (1.5 ... 5.5) µm; InSb: (1.5 ... 5.7) µm |

| Pitch | 15 µm |

| Detector | MCT or InSb |

| Detector format (IR pixels) | (640 × 512) |

| Image format with opto-mechanical MicroScan (IR pixels) | (1,280 × 1,024) |

| Image recording principle | Snapshot |

| Readout mode | ITR / IWR |

| Aperture ratio | f/3.0 |

| Detector cooling | Stirling cooler |

| Temperature measuring range | (-40 … 1,500) °C, up to 3,000 °C* |

| Measurement accuracy | ± 1 °C or ± 1 % |

| Temperature resolution at 30 °C | MCT: Better than 0.02 K; InSb: Better than 0.025 K |

| Frame rate (full / half / quarter / sub frame) | MCT: Up to 232/828/2,300/3,725 Hz; InSb: Up to 355/670/1,200/5,000 Hz |

| Window mode | Yes |

* Depending on model

** In selected measurement ranges

Configure Your Camera System

Each measurement or testing task has its own characteristic basic conditions. For getting optimal results camera, detector and lens have to be perfectly matched to one another. The field of view calculator helps you to determine the appropriate combination.

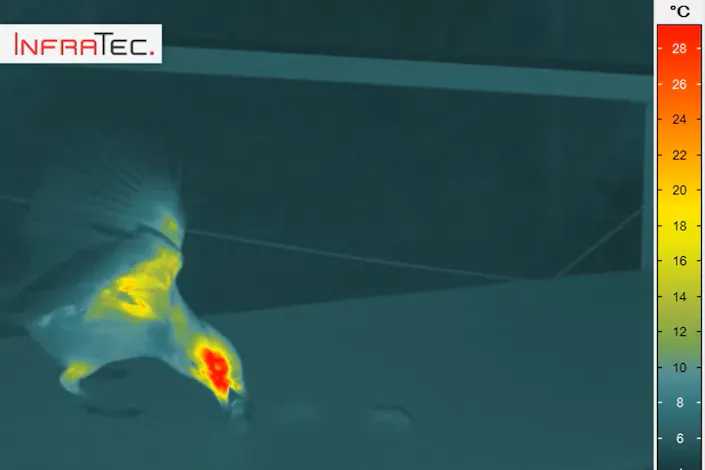

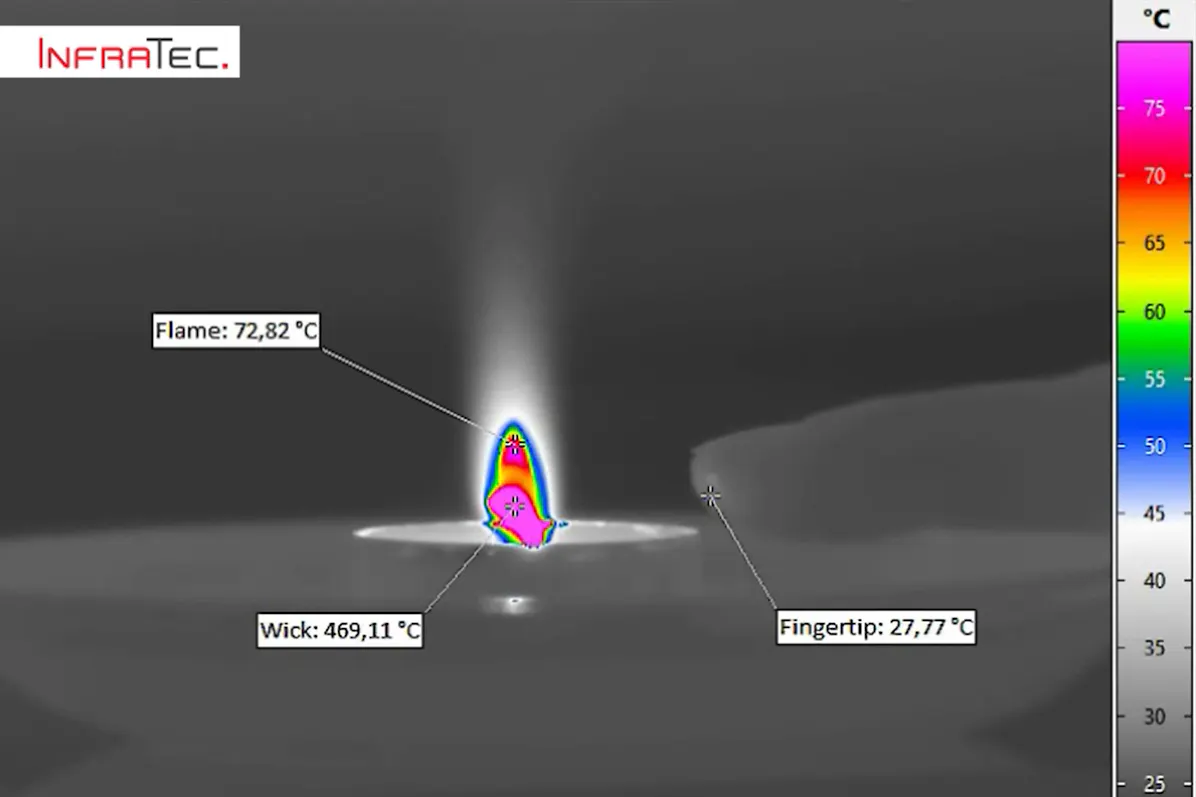

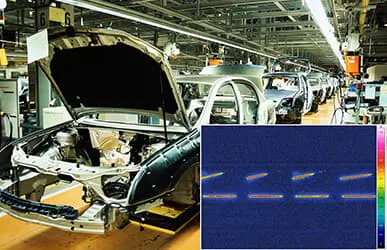

The ImageIR® 8300 hp in Use for Research Applications

The SPIRIT Project

InfraTec expands its know-how in the field of thermography by participating in various research projects. The ImageIR® 8300 hp is used, for example, in the SPIRIT project. A total of eight partners from Austria, Italy and Germany are working together to simplify the use of inspection robots for quality control of complex shaped parts. Up to now, robots for solving such tasks have been programmed specifically for each application. This is usually very time-consuming and causes high costs. In future, in contrast, a simple set-up will be sufficient for the robot-supported testing task.

Comprehensive Thermography Evaluation Software for Efficient Operation

The software family IRBIS® 3, which was developed by InfraTec, is part of a complete system of the camera series ImageIR®. The comfortable and professional thermography software IRBIS® 3 professional offers a wide range of analysis- and editing tools to analyse sophisticated thermal investigations. The combination of ImageIR® together with the professional thermographic software meets all requirements that are set as standard for efficient high-performance tools for thermographic investigations.

Product Flyer

Get all the information you need at a glance in our product flyers

Do You Want to Know More About the InfraTec Service?

Our experienced service team will be happy to assist you.

Choose Your Infrared Camera

Choose from more than 30 infrared camera models. Our product range includes includes compact and system cameras, high-end systems as well as zoom cameras and OEM solutions.