ImageIR® 8800

High resolution and speed – the cooled long-wave infrared camera

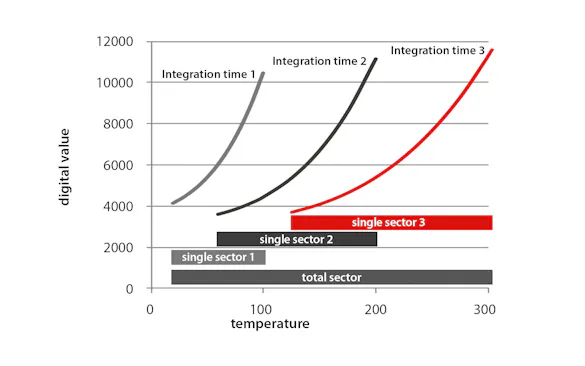

Calibration of a multitude of calibration curves for precise temperature measurement

Detection of smallest details with detector of (640 × 512) infrared pixels

Snapshot detector with short integration times

Modular concept for high flexibility

Precise long-time measurements without shutter

Large detector enables highest sensivity

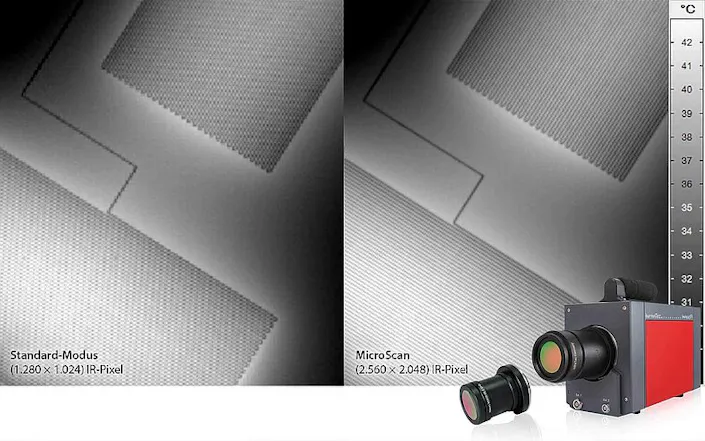

(1,280 × 1,024) IR pixels by genuine camera hardware

Analysis of extreme temperature changes and gradients in full frame

Highly accurate and repeatable measurements

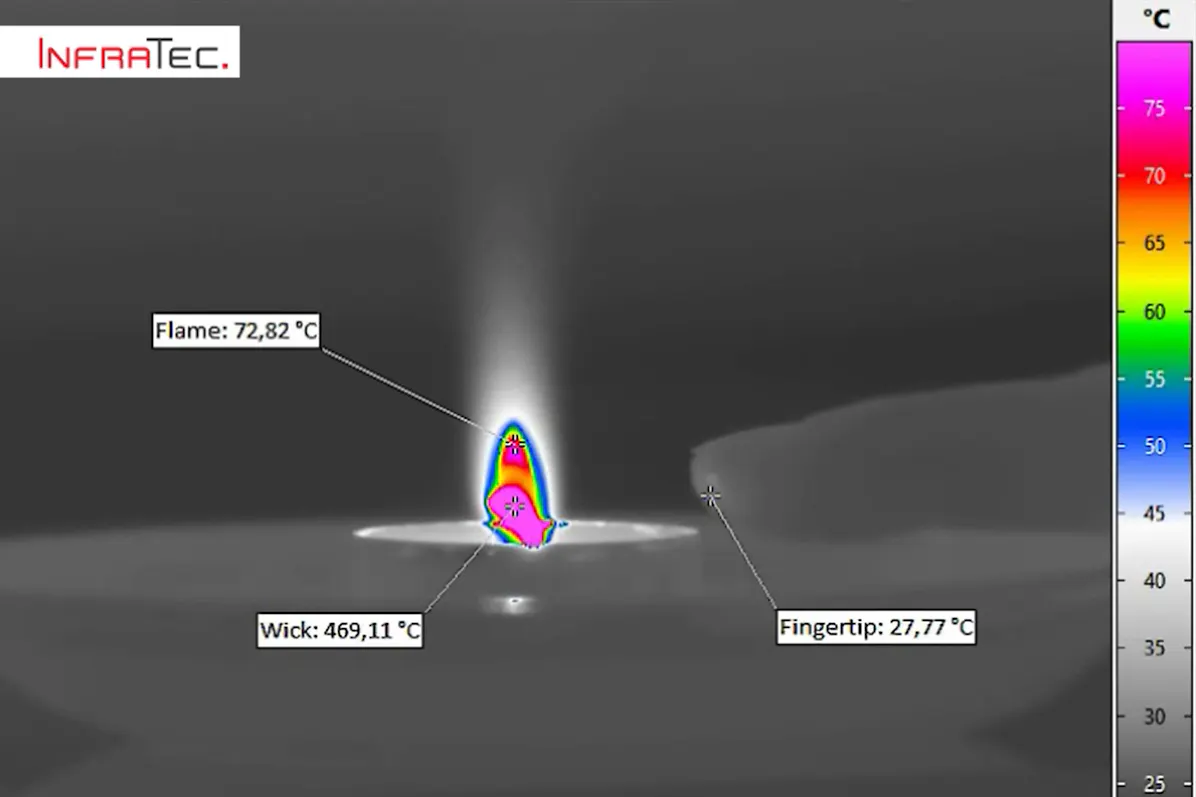

Accurate temperature measurements of fast processes

High-speed, long-distance interference proof data transmission

Measurement in the range of (7.7…10.2) µm

Measure Precisely over a Long Time

A high long-term stability of the thermographic measurement with infrared camera systems of the ImageIR® 8800 series is achieved without any shutter by an excellent thermal decoupling of the electronics module which will emit heat during its operation from the optical and detector module being most important for the signal receipt. Also external temperature changes is being taken care of by a multitude of calibration curves and internal calibration routines.

Download HDR White Paper

Download the HDR white paper to get further information how it works and what the benefits are.

Increase Your Flexibility by Using the Modular Design Concept

The ImageIR® series is based on a modular concept and allows for successive upgrading and changes of powerful components like motorized lenses or a high-speed shutter. Already in its basic configuration it can be delivered with different detectors which support your application the best way. Like this you will always remain flexible and optimally adapt your camera systems to your respective needs.

Measure Correctly with an Accuracy of +/- 1%

If your measurement object has a temperature of 18.7 °C will always measure 18.7 °C and exactly this is taken care of by the infrared camera systems of the ImageIR® 8800 series. You can rely on a correct measurement with an accuracy of +/- 1%

Easily Transfer Your Radiometric Data to the Computer

You will be able to work with both radiation proportional data formats and also directly with temperature data in °C or °F. You will receive the data by setting your specific parameters in the easy handling acquisition interface of the ImageIR® series at a frame rate of up to 2.5 kHz.

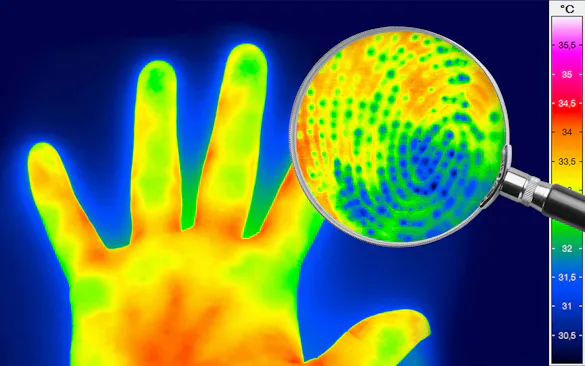

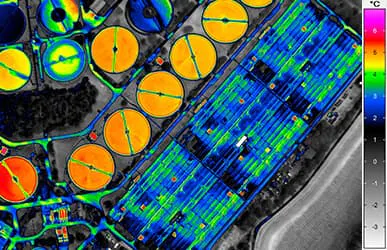

Highest Homogeneity will Provide you with a Brilliant Picture

A infrared camera out of the ImageIR® 8800 series offers highest homogeneity by combining cooled detector technology of the latest generation with other high precision components. Precise thermography measurements therefore will not be influenced by any fixed pattern and thermal images will be absolutely clear.

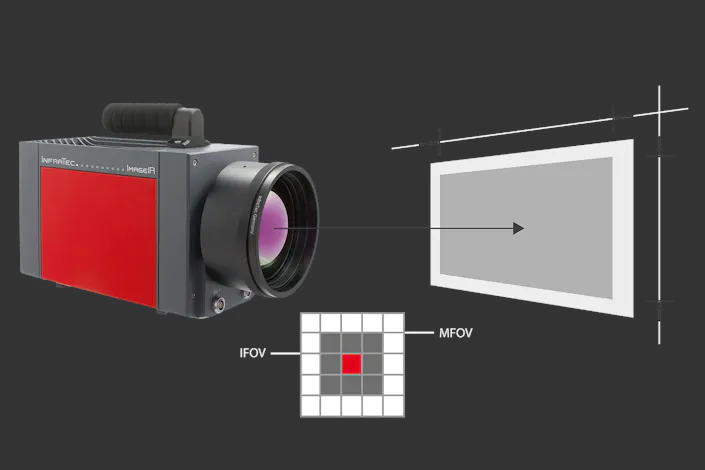

Avoid Measurement Errors Using Highest Geometrical Resolution of (640 × 512) Infrared Pixels

Compared with digital cameras operating in the visible spectrum thermographic detector technologies still suffer from lower pixel numbers. Therefore every pixel counts as in former times of digital photography. The ImageIR® 8800 series offers you (640 × 512) pixels of the high-resolution detector.

Focus the Thermal Radiation Loss-free with Quality Lenses

In the field of thermography, low temperatures result in lower infrared radiation and thereby in smaller signal for the infrared camera. That is why all the available signal should be used. The lens is the part of the infrared camera getting in touch with the infrared radiation first and therefore it plays an important role. Precision lenses being coated with an anti-reflection film for avoiding disturbtions take care that the whole infrared radiation will be focussed to the detector of the ImageIR® 8800 series. You will find a wide range of lenses like for instance telephoto or wide-angle lenses.

Acquire Thermal Images in a Millisecond of Time

The exact and fast control of the detectors of the ImageIR® 8800 infrared camera series provides the possibility to acquire and analyse thermal images at a time scale of milliseconds. Thereby it allows an easy analysis of fast processes regarding their thermal changes. Thermal images can be stored at a frame rate of up to 100 Hz in full frame mode and provide insights into thermal changes of fast running processes.

Statements of our Customers

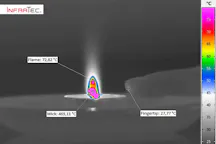

As a satisfied customer and project partner, Deutsche WindGuard Engineering GmbH congratulates on your company’s 30th anniversary. We thank InfraTec for the competent support in our daily operations and the excellent cooperation in research projects like PreciWind. For many years we have been using hardware and software from InfraTec for thermographic flow visualisation and analysis. In our aeroacoustically optimised large wind tunnel Bremerhaven (DWAA), for example, two VarioCAM® HDx head 615 accompany daily operations in thermographic flow visualization primarily of lift profiles from wind energy and aviation. For aerodynamic measurement of wind turbine rotor blades in operation, Deutsche WindGuard uses an ImageIR® 8800 in cooperation with BIMAQ (Bremen Institute for Measurement and Automation).

Technical Specifications

| Spectral range | (7.7 … 10.2) µm |

| Pitch | 15 µm |

| Detector | MCT |

| Detector format (IR pixels) | (640 × 512) |

| Image format with opto-mechanical MicroScan (IR pixels) | (1,280 × 1,024) |

| Image recording principle | Snapshot |

| Readout mode | ITR |

| Aperture ratio | f/2.0 |

| Detector cooling | Stirling cooler |

| Temperature measuring range | (-40 ... 1,700) °C, up to 3,000 °C* |

| Measurement accuracy | ± 1 °C or ± 1 % |

| Temperature resolution at 30 °C | Better than 0.025 K |

| Frame rate (full / half / quarter / sub frame) | Up to 233 / 874 / 2,892 / 14,593 Hz |

| Window mode | Yes |

* Depending on model

** In selected measurement ranges

Configure Your Camera System

Each measurement or testing task has its own characteristic basic conditions. For getting optimal results camera, detector and lens have to be perfectly matched to one another. The field of view calculator helps you to determine the appropriate combination.

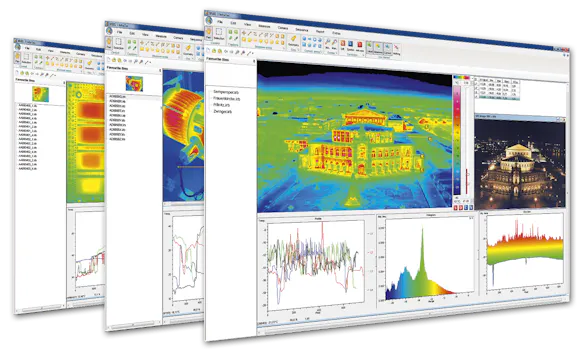

Comprehensive Thermography Evaluation Software for Efficient Operation

The software family IRBIS® 3, which was developed by InfraTec, is part of a complete system of the camera series ImageIR®. The comfortable and professional thermography software IRBIS® 3 professional offers a wide range of analysis- and editing tools to analyse sophisticated thermal investigations. The combination of ImageIR® together with the professional thermographic software meets all requirements that are set as standard for efficient high-performance tools for thermographic investigations.

Product Flyer

Get all the information you need at a glance in our product flyers

Would You Like to Know More?

It is not unusual for tasks to be associated with special requirements. Discuss your specific application needs with our specialists, receive further technical information or learn more about our additional services.

Choose Your Infrared Camera

Choose from more than 30 infrared camera models. Our product range includes includes compact and system cameras, high-end systems as well as zoom cameras and OEM solutions.