Micro-Thermography

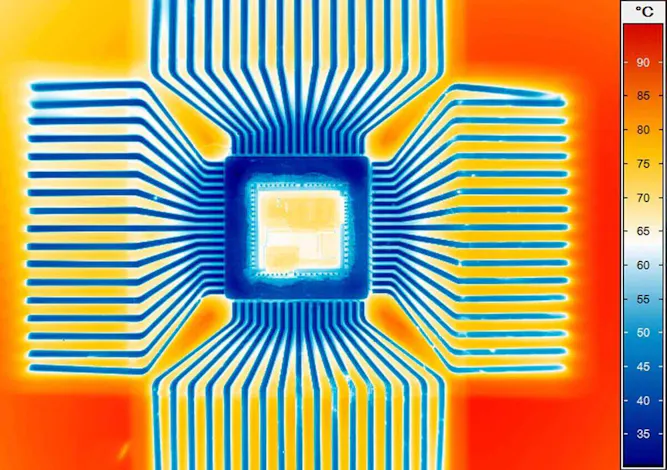

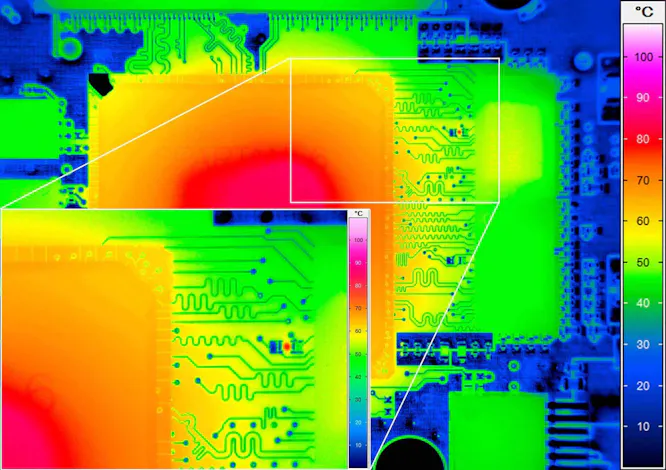

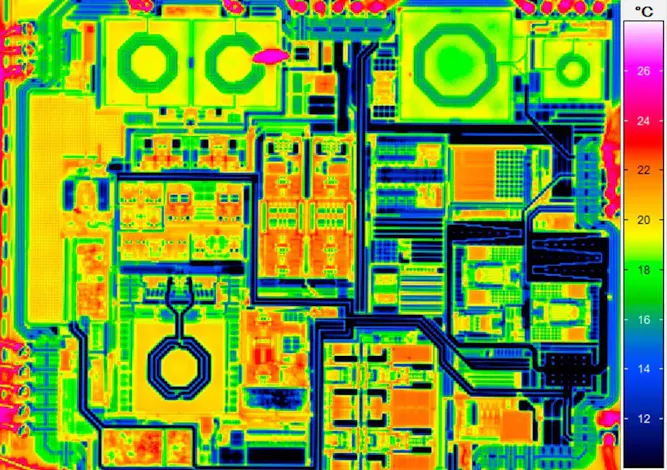

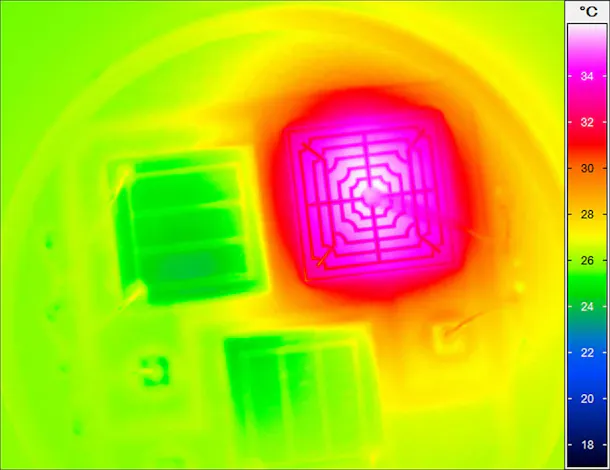

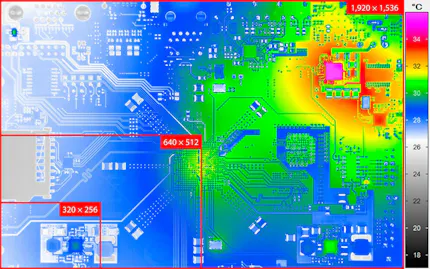

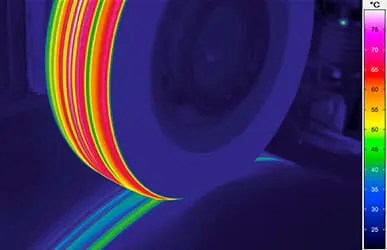

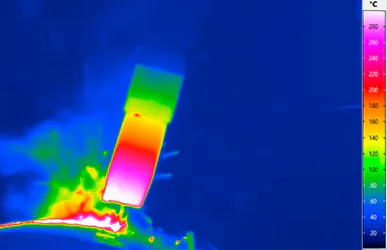

Thermal optimisation of the assembly process and components is a central issue in the development of new products. The temperature distribution of energised PCBs and individual components can be analysed very well by using powerful thermal imaging systems, while hotspots can be tracked in the image area at the same time.

Micro-Thermography Opens Up New Possibilities for Quality Control and Development

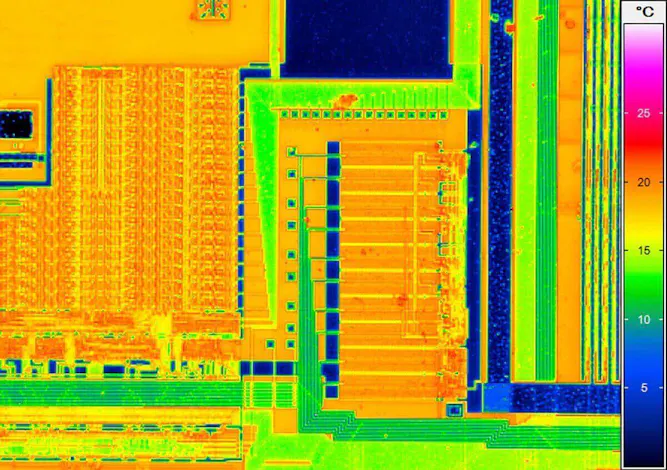

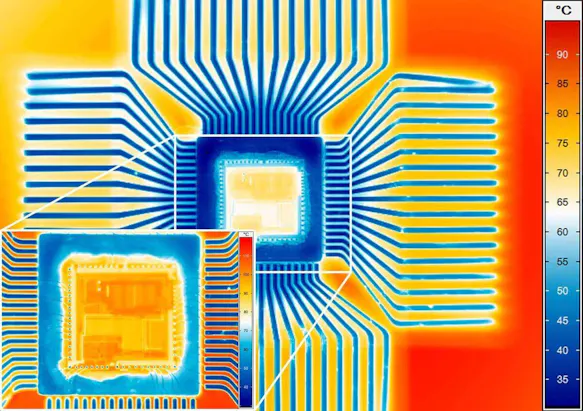

Complex electronics are becoming more powerful and smaller, so that in their development, thermal management is becoming increasingly important. The placement of electronic components on printed circuit boards is done in a small space, so good heat dissipation is necessary. Microthermography allows for the thermal analysis of extremely small structures in the micrometer range, providing a detailed representation of the temperature distribution on complex electronic assemblies and components.

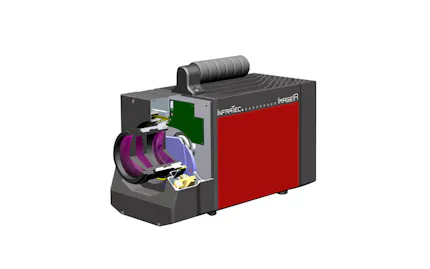

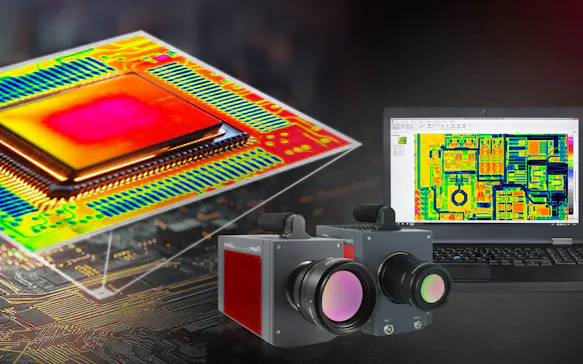

The thermal imaging camera series VarioCAM® High Definition and ImageIR® by InfraTec can be equipped with microscope objectives of different magnification factors.

Using the 8x microscope of ImageIR®, for example, high-resolution detail shots of eletronic assemblies and components can be produced with a pixel size of up to 2 µm. By using the opto-mechanical real-time MicroScan unit of the infrared camera series VarioCAM® High Definition, which is designed for continuous operation, up to (2,048 x 1,536) IR pixels can be achieved. At this resolution, even the smallest defects in measurement areas can still be reliably detected.

Live Online Events 2026

Online Events On Demand

Micro-Thermography – Contactless Temperature Measurement in the Micrometer Scale

What are the physical characteristics of micro-thermography?

What are the technical requirements for an IR camera system?

Which selection criteria are important and relevant?

In which application areas is micro-thermography used?

Infrared Lock-in Thermography for Inspection of Electronics and Integrated Circuits

Failure analysis and defect inspection, quality and process control and flexible R&D solution

Hotspot detection on printed circuit boards, integrated circuits, semiconductor material and multi-chip modules

Detection of faulty thermal connections of heat sinks, short circuits, soldering defects and wire bonding errors

Complementary technical lecture Semiconductor IR-LIT Analytics – Challenges and Case Studies from Marko Hoffmann; Infineon Technologies Dresden GmbH & Co. KG

Would You Like to Know More?

It is not unusual for tasks to be associated with special requirements. Discuss your specific application needs with our specialists, receive further technical information or learn more about our additional services.

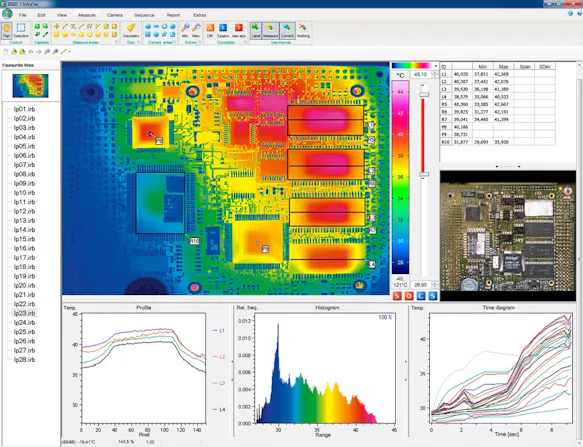

Accurate Readings through Special Software

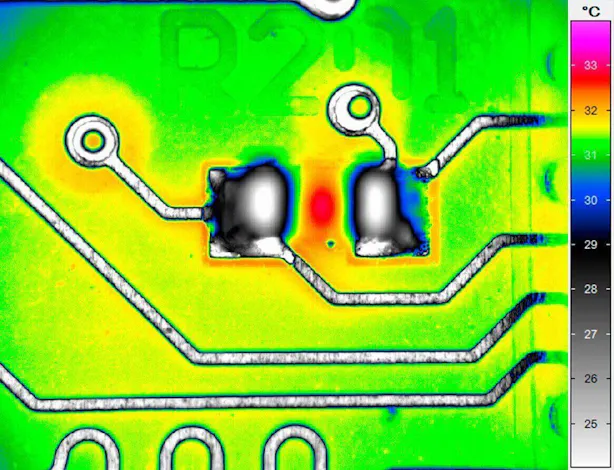

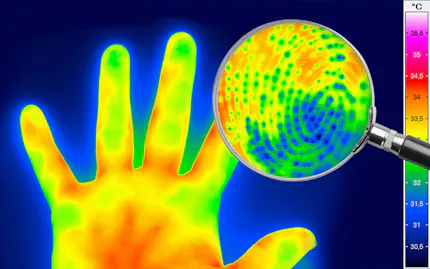

In contact-less temperature measurement, using infrared thermography in electronic assemblies, it should be noted that objects often have different emission behavior. For example, ceramics and plastics have a relatively high emissivity, while copper conductors and leads are very low.

When using the correction models for automatic pixel-wise adjustment of the emissivity, as contained in the thermography software IRBIS® 3 from InfraTec, measurement errors can be avoided effectively. This function is performed after recording the emissivity distribution of a uniformly-heated test specimen. In the subsequent thermographic images, a precise correction of the emission levels takes place, thus giving a correct determination of the temperature of each individual object.