Thermography in the Electronics & Electrical Industry

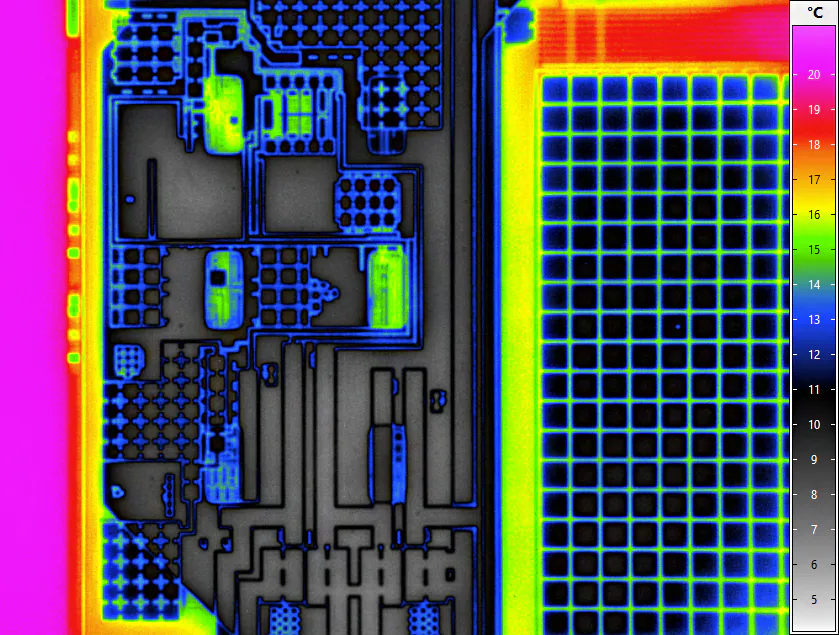

Invisible defects, hotspots, unstable prototypes? Our thermography systems make even µm structures and µK differences visible— contactless, fast, and precise. Ideal for development, failure analysis, or inline quality assurance.

InfraTec Cameras and Systems for Electronics

Get maximumIR resolution – large & small test objects: detectors with up to (2,560 × 2,048) IR-pixels; pixel resolution < 1µm

Measure the smallest temperature differences – precise & innovativ: < 0,015 K; with lock-in down to the µK range

Detect the shortest reactions – fast & synchronous: up to 105 kHz, trigger, 10 GigE

Benefit from customized solutions – modular & scalable: lenses, software, complete test stations

Non-contact Measurement in Electronics with an Infrared Camera

The thermographic inspection of electronic components and assemblies is an established test procedure for failure detection and quality management – from the development of first prototypes to serial production.

Areas of Application for Thermal Imaging in Electronics

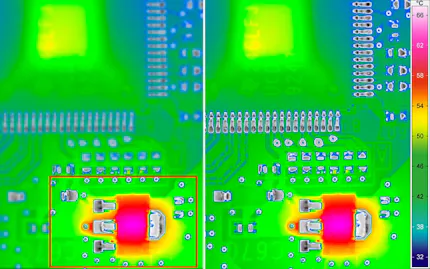

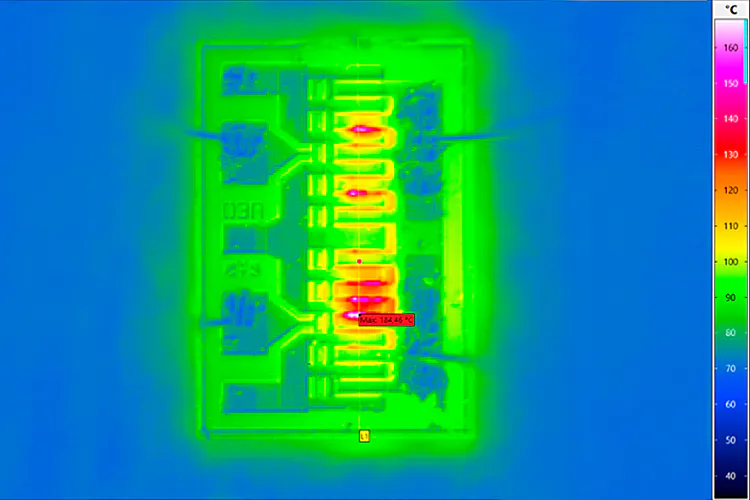

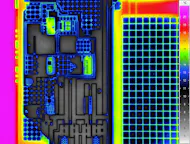

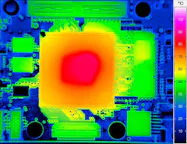

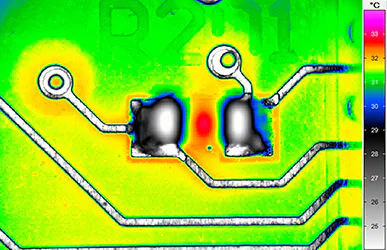

Electronic failure analysis for hotspot detection

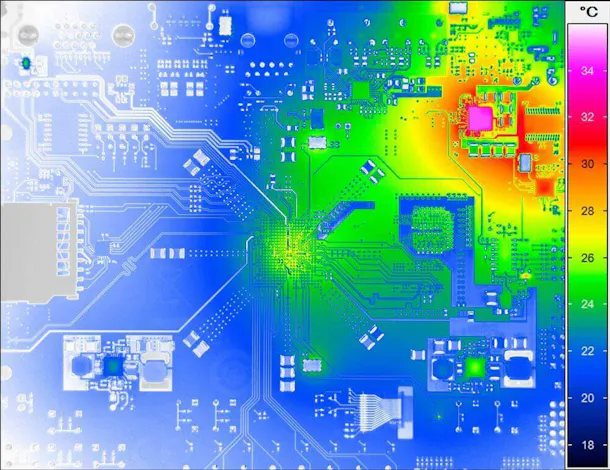

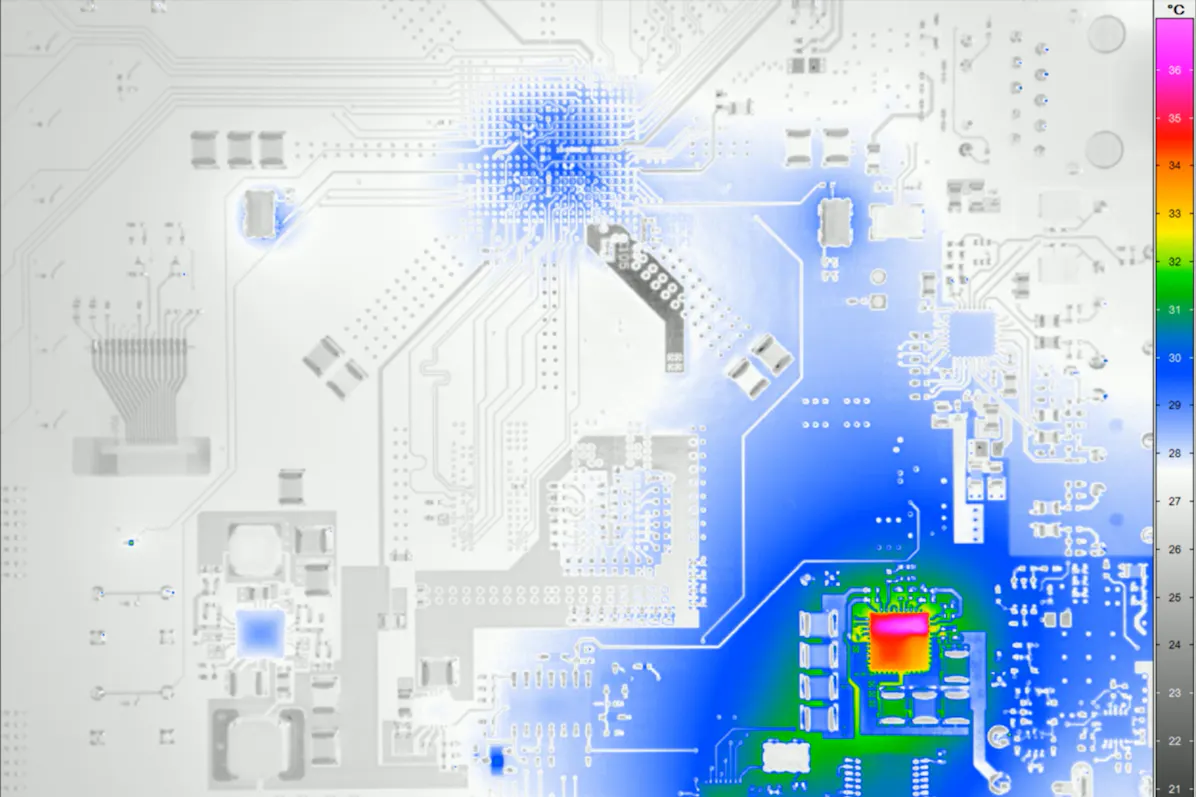

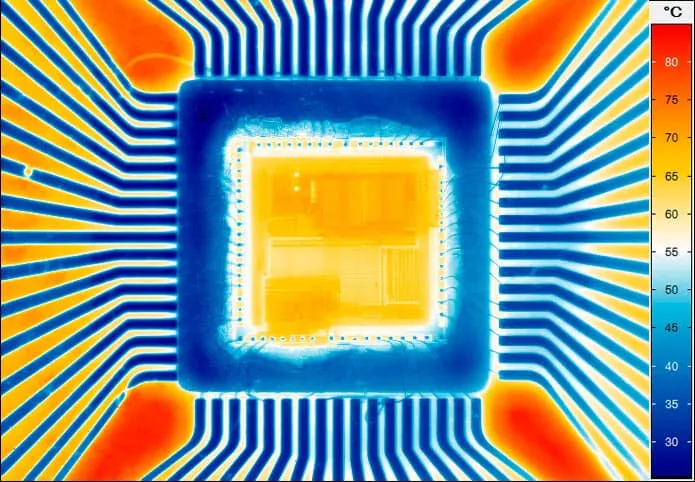

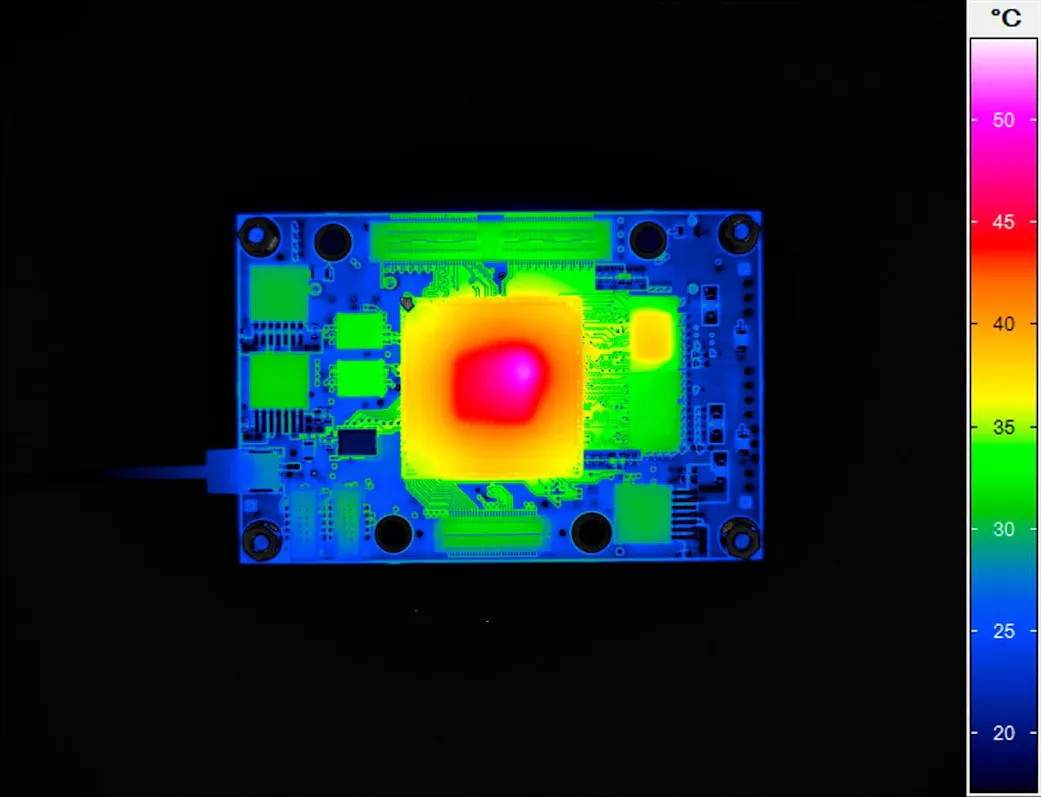

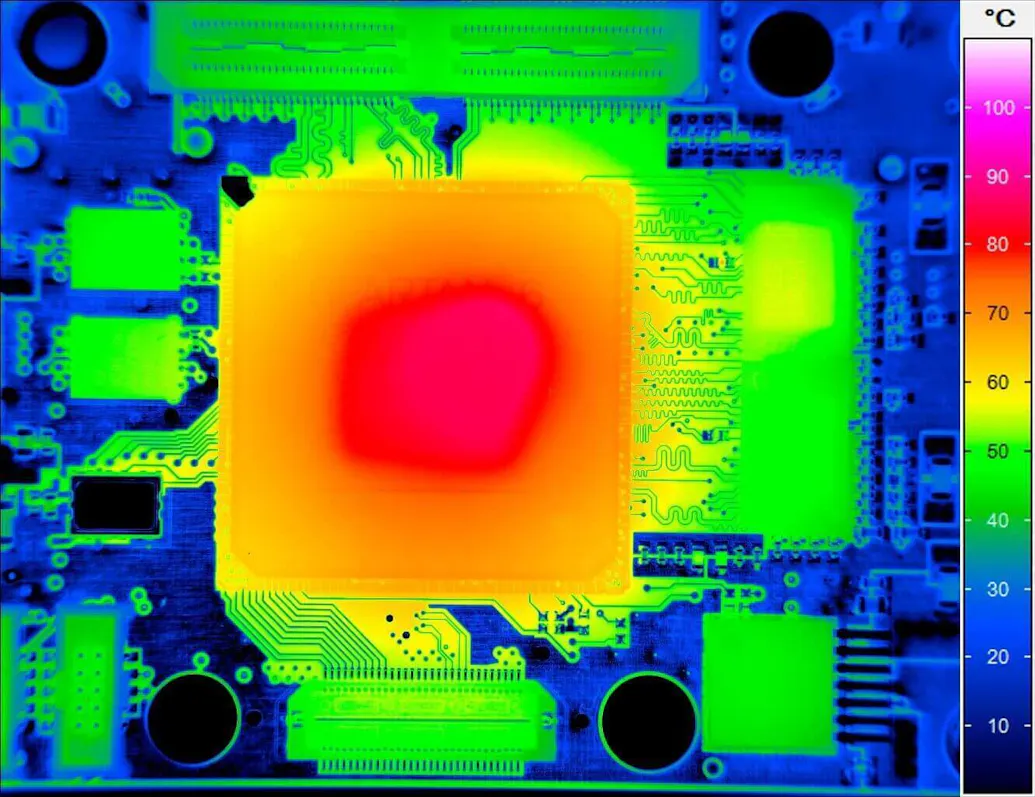

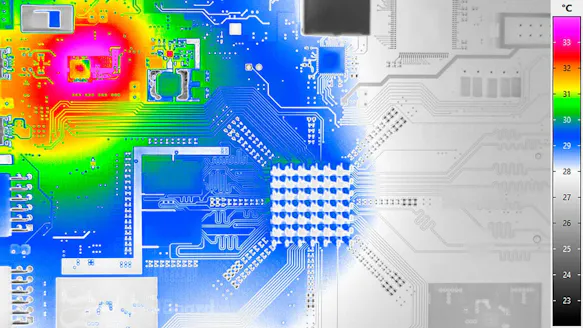

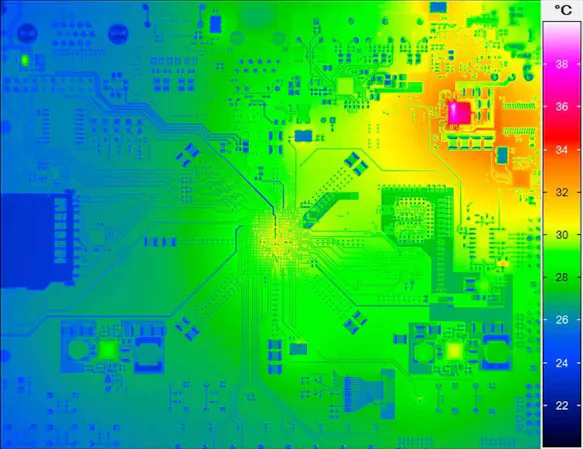

Thermal Mapping, measurement of atypical temperature distributions on the surface of printed circuit boards, integrated circuits, and multichip modules to detect connection faults and defective components

Thermal design

Thermal management, temperature-time behavior, board layout, analysis of cooling concepts, thermal design process

Service life analysis

Analysis of temperature behavior during load cycles as well as during switch-off and switch-on cycles, investigation of thermal aging, and validation of simulation calculations related to self-heating

Inline quality assurance in electronics manufacturing

Versatile tool for quality assurance of process parameters and products during production

Thermography Allows the Detection of

elevated contact resistance,

higher impedance caused by cable constriction

hidden cracks in connection points,

power losses due to high frequency (HF) mismatch,

faulty thermal connections of heat sinks,

short circuits, soldering defects such as cold solder joints,

thermally active watermarks as a protective measure against cyberattacks in the hardware and software area

design of boards and testing of cooling concepts

Advantages of Thermal Imaging in these Fields of Application

Safe temperature measurement even on live parts

Complete recording of the temperature distribution and its temporal progression of complex assemblies during operation

Does not affect the high frequency (HF) impedance of the test object or the heat dissipation from it, which helps to reliably avoid corresponding measurement errors

Clearly determining temperature differences in the µK range

Information on thermal characteristics of components and circuits as early as the design phase

Live Online Events 2026

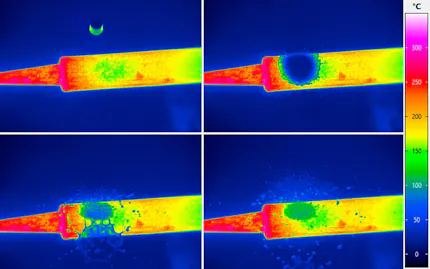

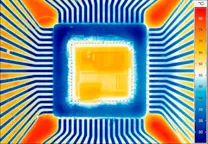

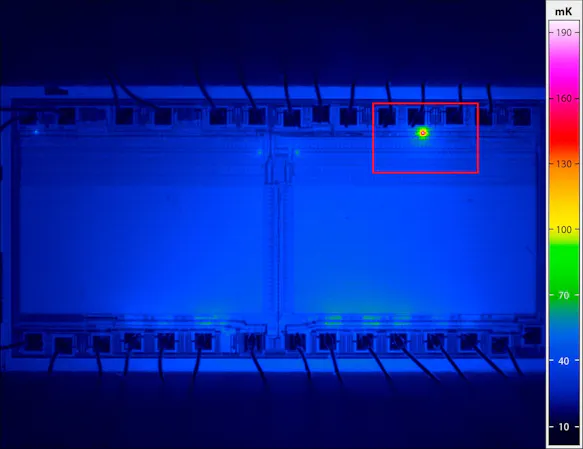

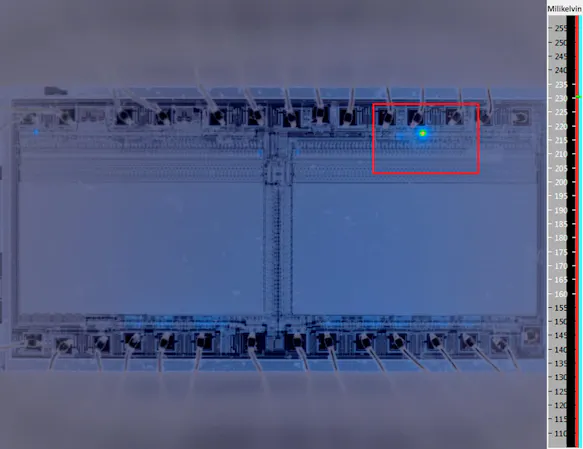

Lock-in Thermography: Clearly Determine Temperature Differences in the µK Range

Thermal imaging has become a standard procedure in electronics. With increasing miniaturization and ever lower supply voltages, failure analysis is becoming more complex. Classic infrared cameras with resolutions of up to < 20 mK are sufficient in many cases, but they do have their limitations.

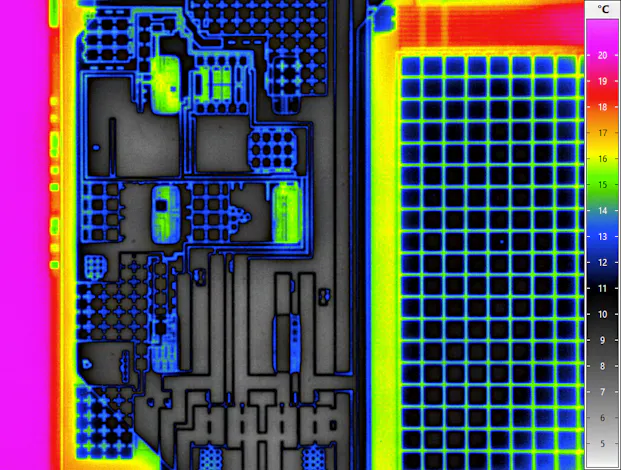

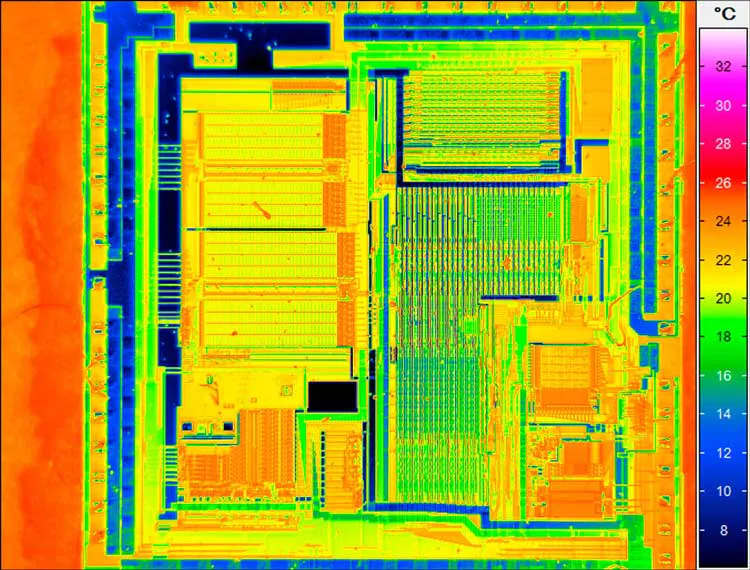

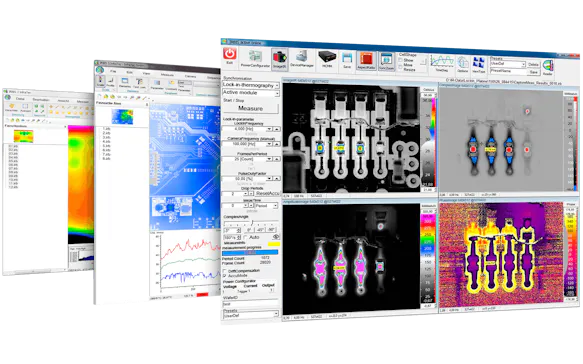

Lock-in Thermography is used to detect minute temperature differences in the µK range. In this process, the test object is analyzed non-destructively using periodic excitation. When using the lock-in method, the measurement time increases significantly compared to real-time measurement as the desired resolution increases and can take several minutes. It is therefore particularly helpful if such measurements can be made in one step using a large-format, high-resolution camera.

Benefits at a Glance:

Highest sensitivity: detect temperature differences in the µK range

Non-destructive analysis: Reliably detect defects through periodic excitation

Optimal results for complex components: Thanks to large-format, high-resolution cameras

Improved efficiency: Less stitching, less effort, lower costs

Detection and allocation of faults in the µK range

Electronics and Semiconductor Module Testing by means of Lock-in Thermography

Find out in our white paper how you can use lock-in thermography to detect faults in electronic and semiconductor components. Benefit from our practical tips and achieve the best possible measurement results with the E-LIT test bench from InfraTec.

Fields of Application for Thermography in Electronics Testing

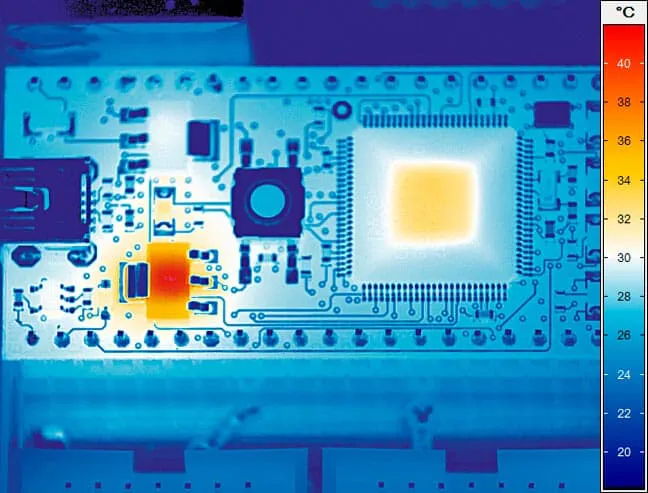

Thermography is now a key tool in electronics development and manufacturing. It helps engineers and quality managers visualize heat distribution, identify sources of error at an early stage, and ensure the reliability of electronic assemblies. From the initial design phase up to series production, it provides valuable information for stable processes and high-quality products.

Electronic Failure Analysis and Hot-spot Detection

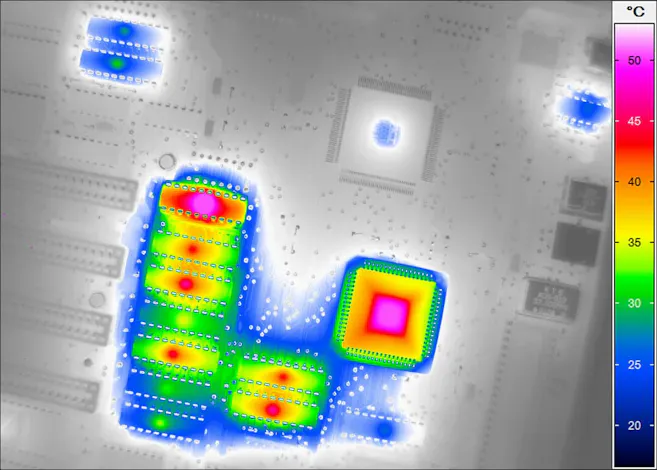

Failure analysis using thermography is essential for investigating the causes when the function of electronic products is impaired or safety-related problems occur. Infrared cameras allow accurate identification of atypical temperature distributions, both in terms of area and spatially. When high-resolution cameras are used in conjunction with lock-in thermography, even the slightest temperature differences in the µK range can be measured. High geometrical resolution enables analysis up to the smallest details.

Examples of Applications for Electronic Failure Analysis

Reliable detection of increased resistance during heat transfer

Detection of thermal anomalies in integrated circuits and their precise localization

Locating short circuits and other defects

Perform electronic circuit testing on integrated circuits, electronic circuits and power electronic circuits for hot spots

thermos optical failure analysis in PCB design in the event of overheating

3D depth analysis of faults in multilayer printed circuit boards and multi-chip modules by adjusting the lock-in frequency

Electronics testing to identify thermal bridges, overheating, and other anomalies in electronic devices and circuits

Advantages of Thermal Imaging in Failure Analysis

Early detection of defects and safety-related weak points

Full-surface visualization of atypical temperature distributions in real time

Non-destructive analysis even for sensitive or complex assemblies

High precision up to the µK range thanks to lock-in thermography

Rapid localization of the cause instead of merely measuring symptoms

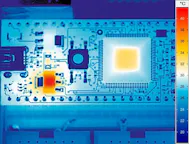

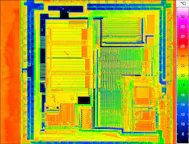

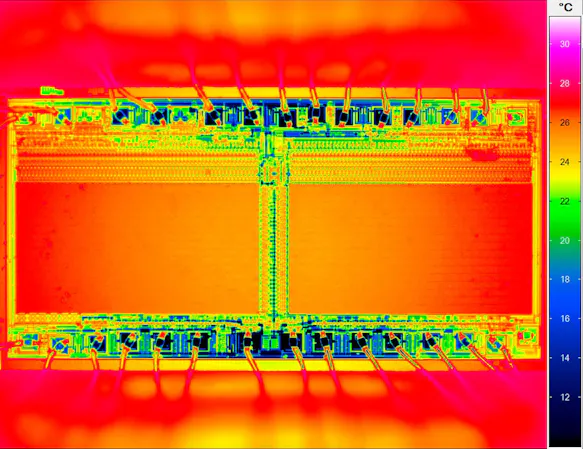

Thermal Design – Thermal Management Layouting

Thermal design of electronic components is a key factor in the development of new chip technologies and applications in power electronics. Thermography can be used for thermal mapping (the spatial acquisition and evaluation of the temperature distribution on electronic components) to identify components with excessive heat generation and mutual thermal interactions between components at an early stage. As a result, early adjustments to prototypes can significantly reduce development costs.

Examples of Applications in Thermal Management Layouting

Analysis of temperature development and heat dissipation in PCB (printed circuit boards) design

Sensible arrangement of components

Determination of the optimal operating points of components

Optimization of energy processing in the field of power electronics

Improvement of heat distribution in switching power supplies and power supply systems

Development of strategies for cooling and heat dissipation under real conditions

Thermal management for quality assurance

Validation of simulation calculations for self-heating of electronic objects

Advantages of Thermography in Thermal Design

Full-surface display of temperature distribution instead of selective measurement helps to ensure that errors are not overlooked

Non-contact and non-destructive, even with sensitive components

High temporal resolution to visualize dynamic heat processes

Service Life Analysis

When developing new electronic components or assemblies, there is initially no application-specific data or information available on service life and performance losses. Predicting these parameters as accurately as possible can be a decisive competitive advantage. Manufacturers and developers therefore carry out complex temperature or load cycle tests to simulate the aging of electronic components.

The high reliability of InfraTec infrared cameras pays off, especially in 24/7 long-term and reliability tests. With the latest models, programmed measurement series for long-term and stress tests can be stored directly on the camera's internal memory (SDK). Add-ons to the IRBIS® 3 analysis and evaluation software also enable the use of programming and development environments that facilitate real-time data acquisition and signal processing.

Remote control reduces sources of interference such as camera shake when touching the camera.

Examples of Applications in Service Life Analysis

Analysis of temperature development during electrical, thermal, or mechanical stress tests on and around electronic objects

Measurement of temperature-time behavior during long-term tests

Advantages of Thermal Imaging in Service Life Analysis

Early prognoses on the service life and performance losses of electronic components

Realistic simulation through temperature and load cycle tests

Complete documentation of temperature-time curves during long-term tests

High reliability in continuous operation (24/7) for valid results

Reduction in costs and risks, as weak points are identified before market launch

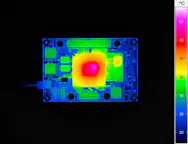

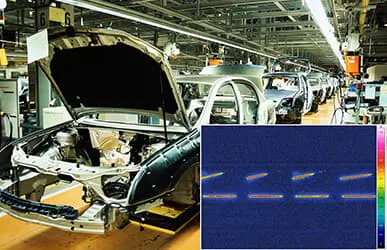

Electronics Manufacturing

In electronics manufacturing, thermographic temperature measurement is used as a versatile tool in quality assurance.

Application Examples in Electronics Manufacturing

Permanent monitoring of critical technological parameters

Inline inspection of products in production

Final functional testing

Advantages of Thermal Imaging in Electronics Manufacturing

Inline quality control during production without interrupting the process

Early failure detection → lower rejection rates, increased process stability

Contactless analysis, even on sensitive or live components

Fast end-of-line analysis for reliable product release

Continuous thermo optical process monitoring of critical parameters for reproducible quality

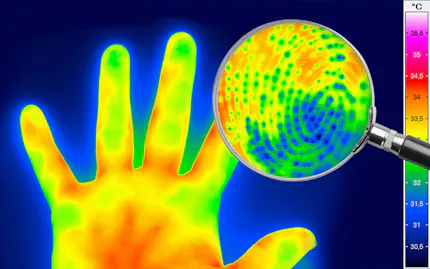

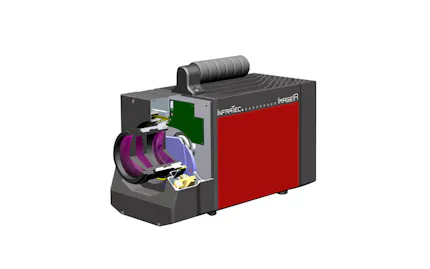

High-performance Thermography Systems by InfraTec

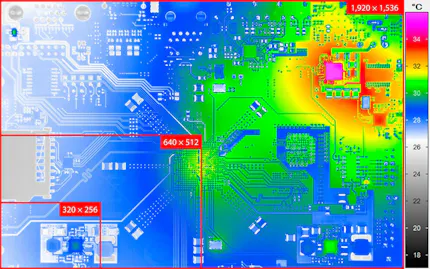

up to (2,560 × 2,048) native IR pixels for analysis of complex assemblies – 16 times the resolution of standard VGA cameras with (640 × 512) pixels

with pixel resolutions of less than up to 1.3 µm with InfraTec's microscopes and even less than 1 μm using SIL lenses

allow easy manipulation of the DUT (Device Under Test) during measurement

between defective and intact structures in the range of a few microkelvins due to high thermal resolution up to < 0.015 K or in the µK range in combination with the lock-in method

of up to ± 1 °C or 1% for reliable measurements and comparability

Analysis of very fast temperature pulses in full-frame format or up to 105 kHz in partial-frame mode

Optimal setup for LIT, low jitter, and low latencies

Direct linking of temperature measurements with other process parameters

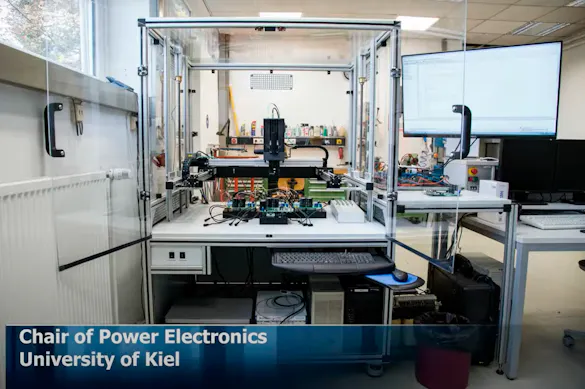

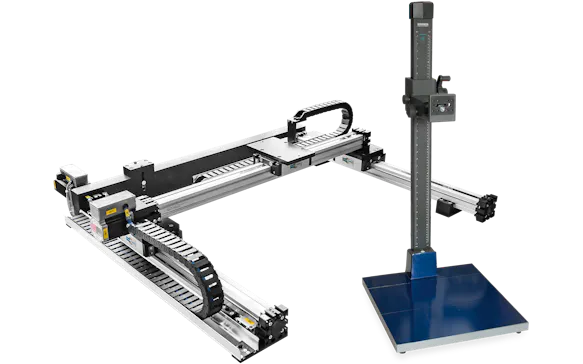

Individual Configuration of Thermographic Systems for Electronics and Electrical Engineering

Depending on the respective task, users can get the equipment configured meeting their specific needs. The starting point will usually be the thermographic camera. Cooled or uncooled detector? Which detector format? Shall the thermographic system support lock-in thermography? How much flexibility is desired for the distance between the measurement object and the camera? What influence does this have on the choice of microscopic lenses and close-ups? Depending on what the answers to these questions will be, InfraTec can offer thermographic systems of various performance levels - from the individual camera to the automated modular E-LIT test bench.

Examples for Thermography in Electronics Applications

Events On Demand

We offer a wide range of on-demand webinars on thermography in the electronics and electrical industry, providing in-depth information on specific applications and solutions.

Infrared Lock-in Thermography for Inspection of Electronics and Integrated Circuits

Micro-Thermography – Contactless Temperature Measurement in the Micrometer Scale

Thermography Solutions for Power Electronics – Precise, Non-contact and High-speed

Find out more about the on demand events

Futher Relatet Online Event Topics

Excellent Coordination of Infrared Camera, Thermography Software and Peripherals

InfraTec places great importance on the optimal interaction between infrared camera and thermography software. In electronics manufacturing, IRBIS® 3 software supports both passive and active thermography methods. It offers powerful tools for users to accurately detect and precisely display defects.

Functions & Benefits for Fault Localization:

Comparison of current thermograms with reference images

Display of amplitude and phase images in lock-in thermography

Individual parameter settings for precise fault localization

When measuring printed circuit boards and hybrid assemblies, the variety of materials (metals, ceramics, plastics) poses a particular challenge. Different surface properties require precise adjustment of the emissivity. With the IRBIS® 3 software, the emissivity for each individual pixel can be both determined and adjusted, automatically correcting the measured temperature to take into account the emissivity and ambient temperature.

Precise Temperature Measurement with IRBIS® 3:

Emissivity can be set individually for each pixel

Automatic temperature correction, including environmental influences

Correction models take into account environmental radiation, the windows used, and the attenuation properties of the measurement path

Lenses

The extensive range of high-quality precision interchangeable lenses allows the field of view to be adapted to almost any measurement situation:

Wide angle, normal and telephoto lenses

Close-up attachments

Microscope lenses

Solid Immersion Lenses (SIL)

Accessories

Additional to the lenses, users can choose from a wide range of accessories:

Excitation controllers for active thermography

Two-axis positioning systems

X-Y measurement tables

Motorised microscope stands

Would You Like to Know More?

It is not unusual for tasks to be associated with special requirements. Discuss your specific application needs with our specialists, receive further technical information or learn more about our additional services.

FAQ Thermography in Electronics

The principle of non-contact thermographic temperature measurement allows the accurate determination of the temperature of small objects with low heat capacity. Even when using the smallest contact temperature sensors, this is often impossible because their heat dissipation frequently distorts the measurement results. In many cases, the use of thermocouples is prevented right from the start by the design or function of the circuit itself. In addition, the structures of electronic measurement objects are sometimes so small that temperature sensors cannot be attached to them at all.

Thermography systems with high geometric resolution can clearly visualize even the smallest structures and, in addition, precisely determine their temperature distribution and temporal progression. With the aid of special macro attachments and powerful infrared microscope lenses, users can thermographically measure hotspots only a few micrometers in size on the surface of components such as semiconductor devices. With the additional use of SIL lenses (solid immersion lenses) placed on the measurement object, even smaller structures can be detected. In combination with appropriate active thermography methods, temperature differences in the µK range can be clearly visualized for fault localization.

Electronic Guide: Electronics / Electrical Engineering

Download our electronic guide “Electronics / Electrical Engineering” and get further information about thermography systems for use in development and production.

Statements of our Customers

Working in R&D, I rely on precise tools, and the Infratec IR camera delivers. The software is intuitive, the ergonomics make it easy to use, and its capabilities are perfect for detailed thermal analysis. The customer support has been excellent. Knowing it's a quality product made in the EU gives extra confidence. Highly recommended.