ImageIR® 9800

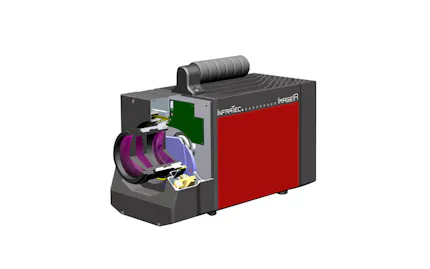

The new ImageIR® 9800 is the ideal device for high-resolution thermographic measurements of highly dynamic processes, even at low object temperatures. The radiometrically calibrated infrared camera, operating in the long-wave atmospheric window (LWIR), delivers razor-sharp images and distortion-free sequences even with short integration times and at low radiation intensity. This is made possible, among other things, by a cooled focal plane array photon detector with (1,280 × 1,024) IR pixels and a pixel pitch of 12 µm.

Short integration times for analyzing fast processes, even at low radiation intensities

Measurement of objects at great distances using telephoto lenses

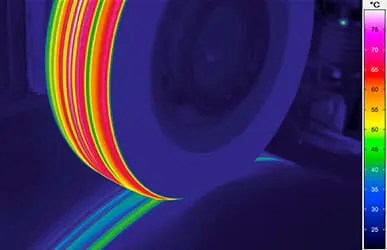

Sharp and distortion-free images even for fast-moving objects

Thermal resolution of 0.03 K and measurement accuracy of 1%

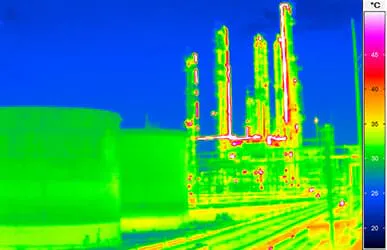

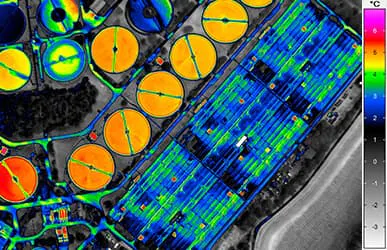

High resolution thermal images for monitoring large areas

Highly accurate and repeatable measurements

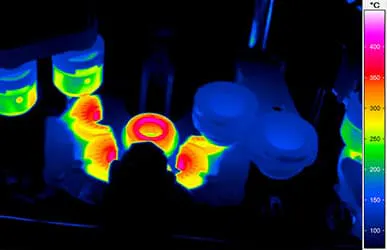

Analysis of extreme temperature changes and gradients in full frame

Precise detection of smallest temperature differences @30°C: 0.03 K

Smaller pixel sizes avoid geometrical measurement errors

Accurate temperature measurements of fast processes

Measurement in the range of (7.7 … 12.5) µm

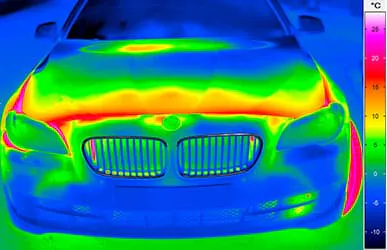

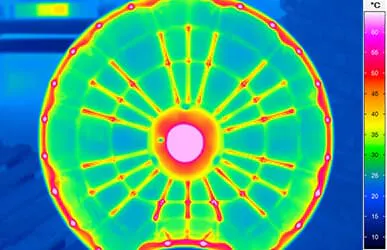

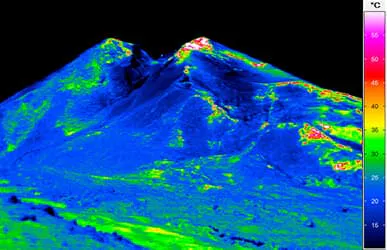

Monitoring the condition of wind turbine rotor blades during operation presents a major challenge for many standard infrared cameras. The ImageIR® 9800, which operates in the LWIR spectral range between (7.7 … 12.5) µm with a cooled photon detector, masters this task with bravura. This camera reliably captures highly dynamic processes requiring extremely short integration times, even at low radiation intensities (e.g., low surface temperatures). Combined with appropriate telephoto lenses, InfraTec's new ImageIR® series model also allows for temperature measurements of objects located at great distances.

Fast Measurement, Broad Temperature Range

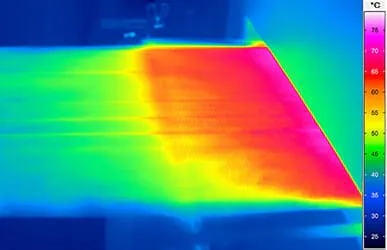

The ImageIR® 9800 allows full-frame images to be captured at frame rates of 180 Hz. In sub-frame mode, the frame rate can be increased to more than three times this value. Thanks to extremely short integration times and snapshot mode – where all detector pixels are exposed simultaneously instead of sequentially line by line – images remain sharp and distortion-free even when test objects move at high relative speeds within the image field. This is essential for accurate, unadulterated thermographic temperature measurement. Precise analysis of fast-moving objects is further supported by a wide range of trigger options for pinpointed, repeatable, time- or event-controlled data recording.

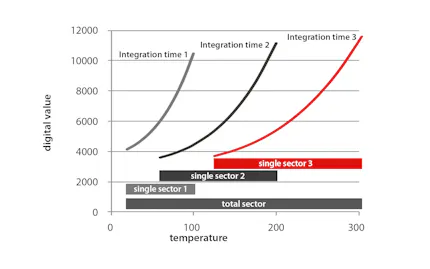

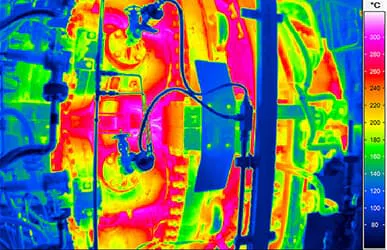

This new high-end InfraTec camera also demonstrates its strengths in tasks such as monitoring combustion gases or exhaust gas flows from vehicles at long distances. Thanks to the HDR function, the ImageIR® 9800 can capture extremely large temperature gradients and variations between -40 °C and 3,000 °C fault-free and continuously. An integrated filter wheel automatically provides filters appropriate for the respective measurement range.

When it comes to detecting thermal signatures and distant objects, the ImageIR® 9800 is the perfect counterpart to the ImageIR® 9400. Both IR cameras are equipped with high-resolution SXGA detectors, cover a wide field of view (FOV), and their spectral ranges – (7.7 ... 12.5) μm and (1.5... 5.5) µm – complement each other perfectly.

InfraTec ImageIR® High-end Infrared Camera Series

Clear Images, Precise Measurement Data

Regardless of the specific measurement task, the ImageIR® 9800 always delivers razor-sharp images with high spatial resolution and an excellent signal-to-noise ratio. With a thermal resolution of 30 mK and a measurement accuracy of 1%, this robust camera is the ideal choice for a wide range of demanding industrial and research applications. The integrated linear motor focus – one of many optional features – simplifies handling and guarantees optimum measurement results, even in challenging scenarios.

Configure Your Camera System

Each measurement or testing task has its own characteristic basic conditions. For getting optimal results camera, detector and lens have to be perfectly matched to one another. The field of view calculator helps you to determine the appropriate combination.

ImageIR® 9800: The Customised Solution for a Wide Range of Measurement Tasks

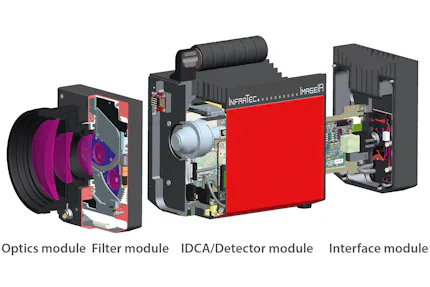

Like all cameras in the ImageIR® series, the ImageIR® 9800 has a modular design and can be equipped with a wide range of lenses. This allows for individual configurations tailored to the user's specific requirements. If the measurement task changes, the infrared camera can be retrofitted to meet the new demands.

A modern interface concept forms the foundation for the performance and flexibility of the ImageIR® 9800 in terms of data acquisition and processing. Via the 10 GigE interface, high-resolution full-frame images with frame rates of up to 180 Hz can be stored and processed directly on a high-performance PC or laptop. The ImageIR® 9800 features four configurable digital and analogue inputs and two outputs for camera control and the output of control signals.

Technical Specifications

| Spectral range | (7.7 … 12.5) µm |

| Pitch | 12 µm |

| Detector | T2SLS |

| Detector format (IR pixels) | (1,280 × 1,024) |

| Image recording principle | Snapshot |

| Readout mode | IWR |

| Aperture ratio | f/2.4 |

| Detector cooling | Stirling cooler |

| Temperature measuring range | (-40 ... 1,500) °C, up to 3,000 °C* |

| Measurement accuracy | ± 1 °C or ± 1 % |

| Temperature resolution at 30 °C | Better than 0.03 K |

| Frame rate (full / half / quarter / sub frame) | Up to 180 / 354 / 672 / 5,800 Hz |

| Window mode | Yes |

* Depending on model

** In selected measurement ranges

*** Simulated values acc. to Johnson criteria for detection, recognition and identification with atmospheric extinction coefficient of 0.2/km and a probability of 50%.

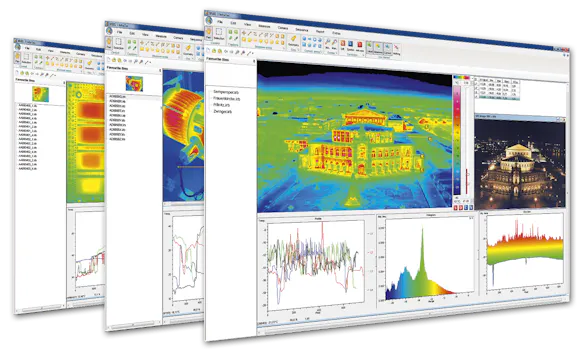

Comprehensive Thermography Evaluation Software for Efficient Operation

The software family IRBIS® 3, which was developed by InfraTec, is part of a complete system of the camera series ImageIR®. The comfortable and professional thermography software IRBIS® 3 professional offers a wide range of analysis- and editing tools to analyse sophisticated thermal investigations. The combination of ImageIR® together with the professional thermographic software meets all requirements that are set as standard for efficient high-performance tools for thermographic investigations.

Data Sheet

Get all the information you need at a glance in our data sheets.

Do You Have Questions? We Are Here For You!

Many requirements call for customized solutions. Our specialists provide personal support – whether you have technical questions, need assistance in selecting suitable system solutions, or want to ensure the optimal use of your infrared camera. Give us a call or send us an email. Together, we will find the right solution.

Choose Your Infrared Camera

Choose from more than 30 infrared camera models. Our product range includes includes compact and system cameras, high-end systems as well as zoom cameras and OEM solutions.